Sandblasting Equipment

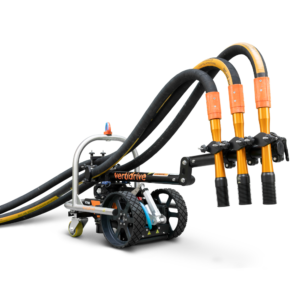

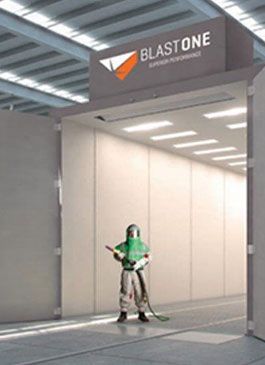

BlastOne has provided sandblasting equipment to commercial contractors since the 1970’s in the corrosion control industry the highest quality sandblasting and painting equipment available. From blast pots, hoses, and nozzles, to airlines, spray tips and even work gloves, we offer a complete line of superior products to help professionals stay comfortable, safe, and profitable on the job site. Our abrasive sandblasting equipment is backed by our quality guarantee and we also offer maintenance, repair, and training services to ensure your tools and supplies last longer and stay running – even in the most trying conditions.

My Account

My Account