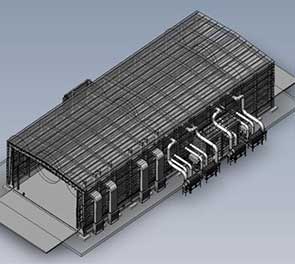

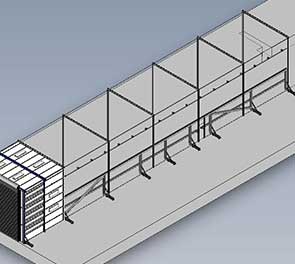

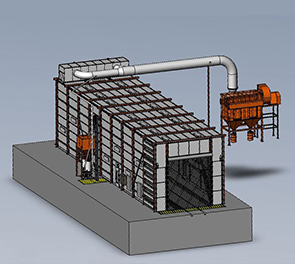

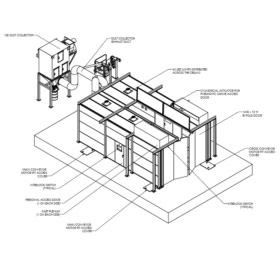

Explore the Blast One heavy-duty robotic blast room at Blast One International’s headquarters in Columbus, Ohio. This booth has a single entry and places all equipment on one side, with exhaust plenums at the rear instead of the usual flow-through design. It features a gantry-mounted Blastman B20 robot with up to eight axes of movement—longitudinal, vertical, and horizontal—using telescopic and joint boom configurations for different applications.

The system includes an oscillating conveyor for abrasive recovery, offering a simpler, more effective alternative to screw augers. Abrasives are lifted to an air wash system that removes dust and fine particles so only clean abrasives are reused. A Blast One dust collector, designed for blasting operations, captures dust during the process and uses an automatic pulsing system to clean its vertical cartridges, improving dust control and operational safety.

My Account

My Account