Dust Collector Buying Guide

Is dust getting in your way? Whether you’re tackling dust on a sandblasting project or controlling hazardous materials, efficient dust collection is essential for a safe, clean, and productive work environment.

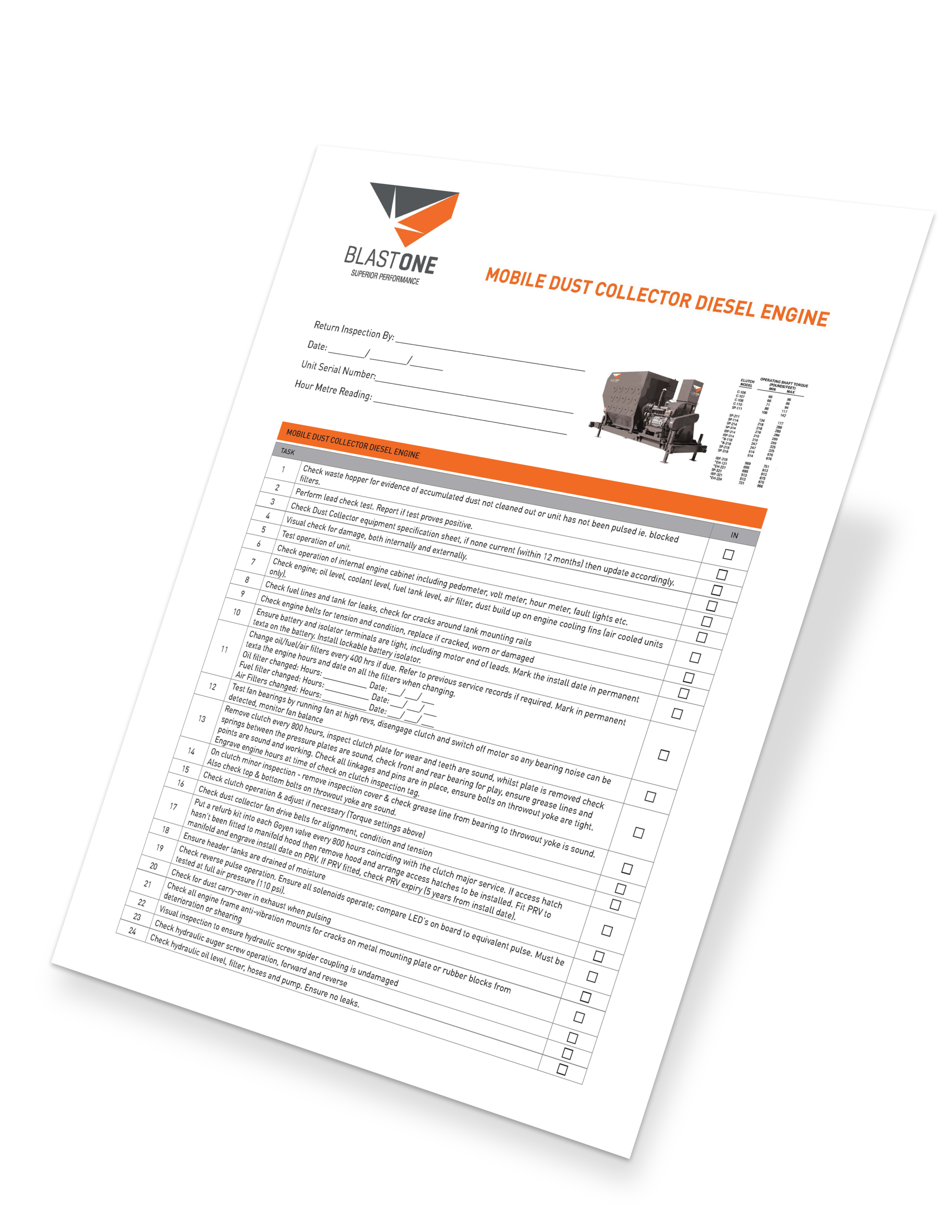

BlastOne offers high-performance portable dust collectors to capture dust generated during sandblasting. Our equipment handles both hazardous and non-hazardous materials, including lead, zinc, and chromates. Choose from units with airflow capacities ranging from 6,000 cfm to 100,000 cfm.

With nearly 50 years of experience, BlastOne is the industry leader in sandblasting dust collection solutions.

My Account

My Account