Garnet Buying Guide

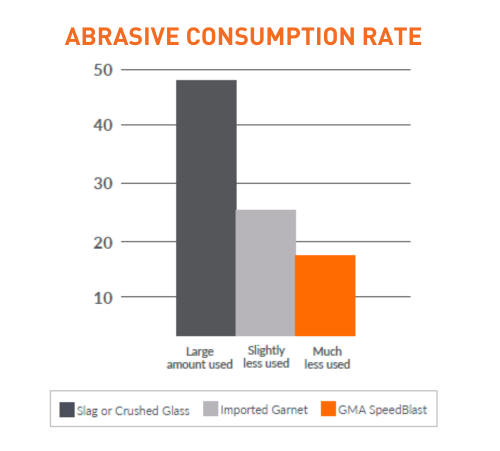

For over 40 years, BlastOne has been partnering with GMA Garnet to supply the cleanest and safest abrasives to contractors throughout the US, Australia, and New Zealand. GMA has produced the highest-quality almandine garnet abrasives for the global abrasive blasting and waterjet cutting industries globally.

Have an upcoming project? BlastOne understands the requirements and project specifications different projects entail. BlastOne has helped contractors on different

projects across the globe for more than four decades, and we understand the requirements that different projects bring. As America’s undisputed industry expert, we understand abrasives. Let’s connect on your next job bid.

My Account

My Account