Sponge-Jet Equipment Buying Guide

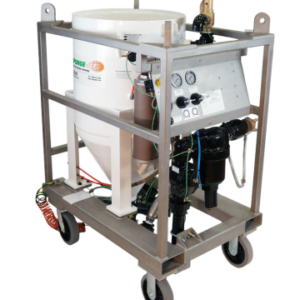

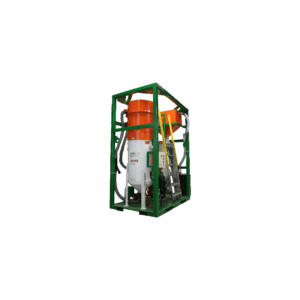

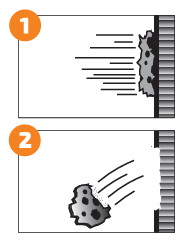

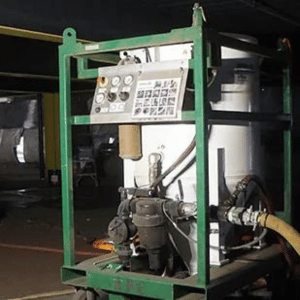

BlastOne is a leading supplier of industrial blasting equipment, with years of experience developing high-production tools to maximize your efficiency. Sponge-Jet equipment utilizes a revolutionary media blasting method to achieve superior cleaning and surface preparation results, while significantly reducing dust and waste.

This translates to a cleaner work environment, reduced media consumption, and most importantly, doubled productivity compared to traditional blasting methods. Learn more about our Sponge-Jet technology and how it can revolutionize your surface preparation process.

My Account

My Account