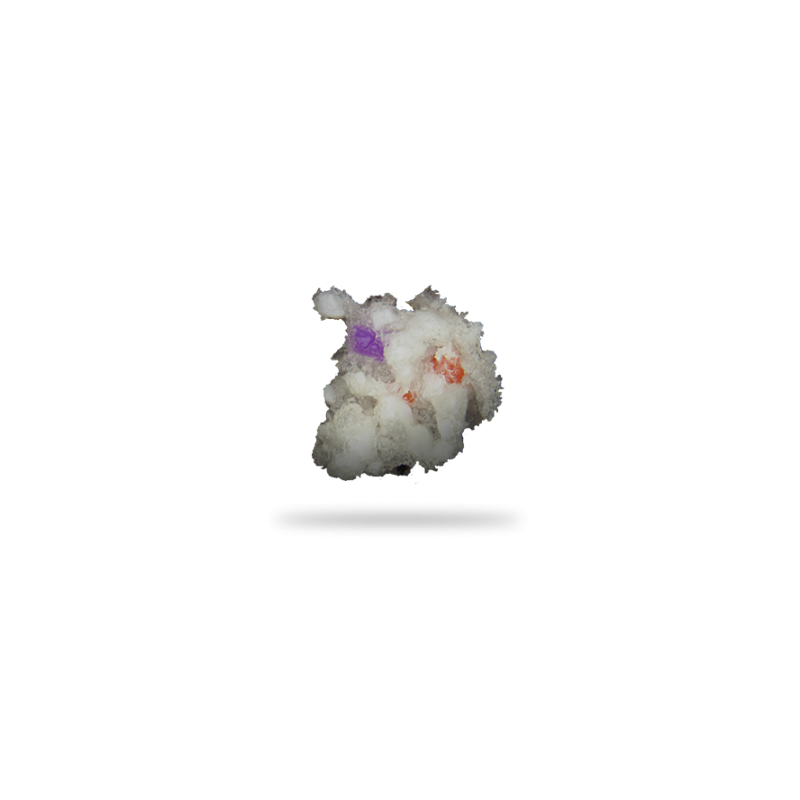

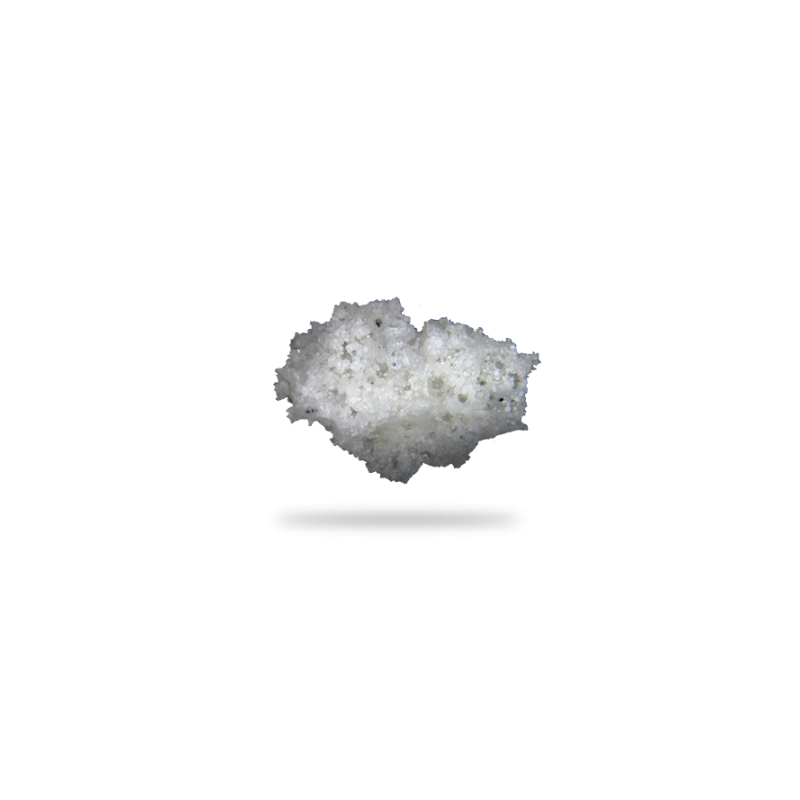

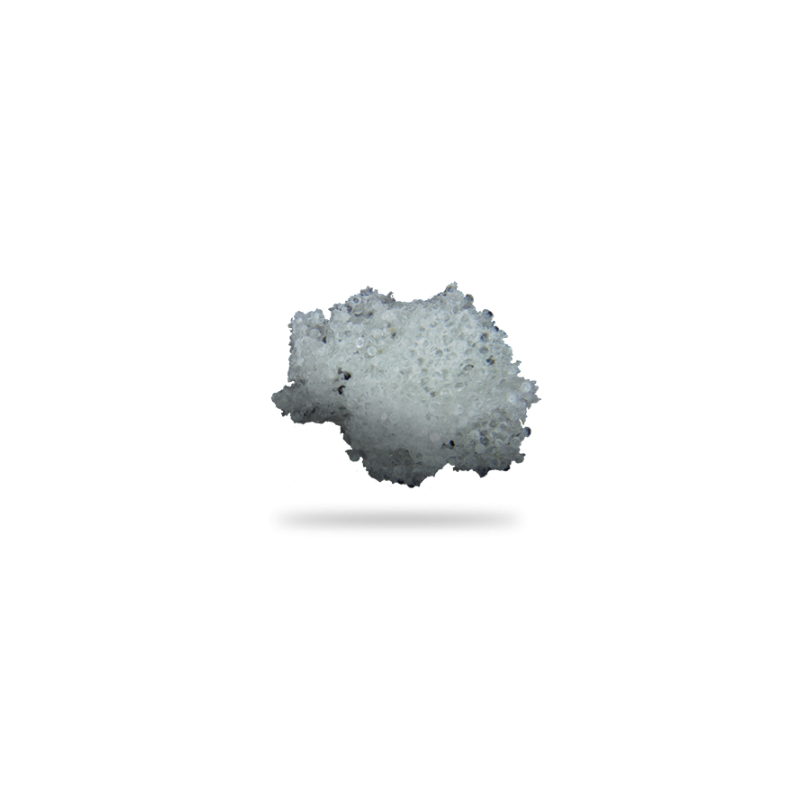

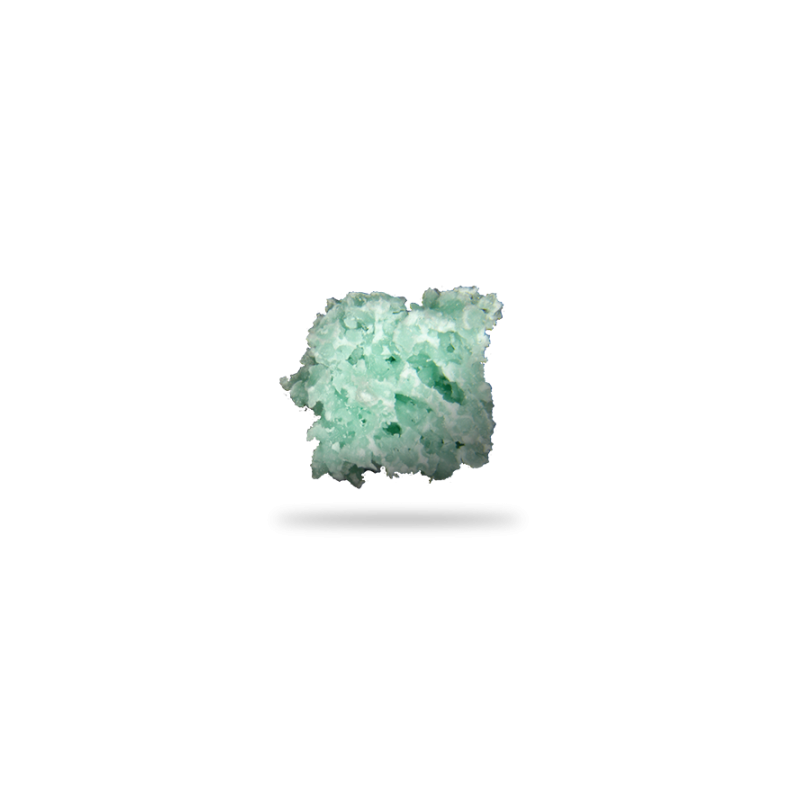

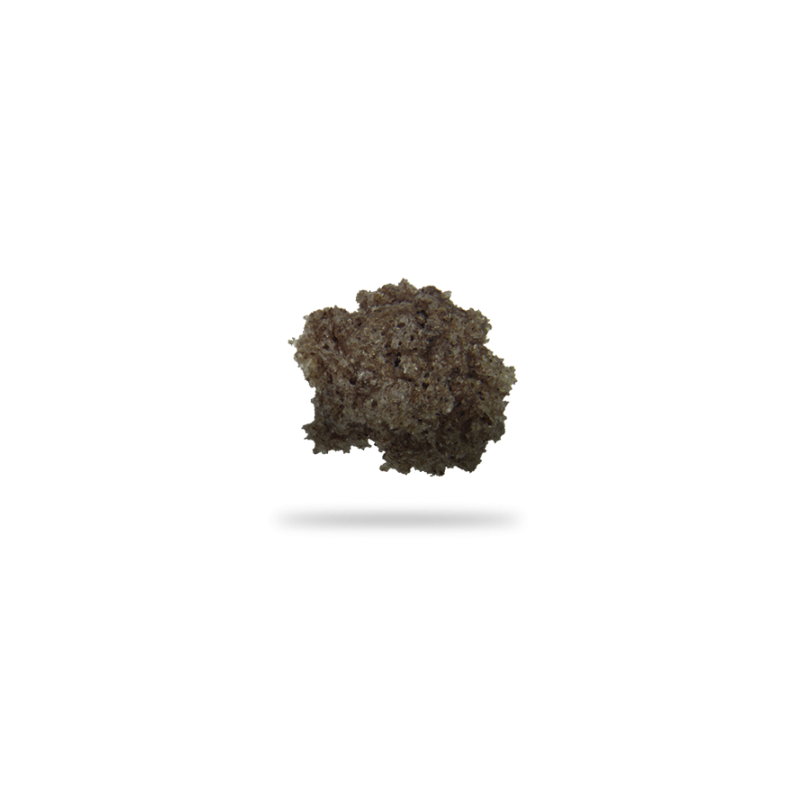

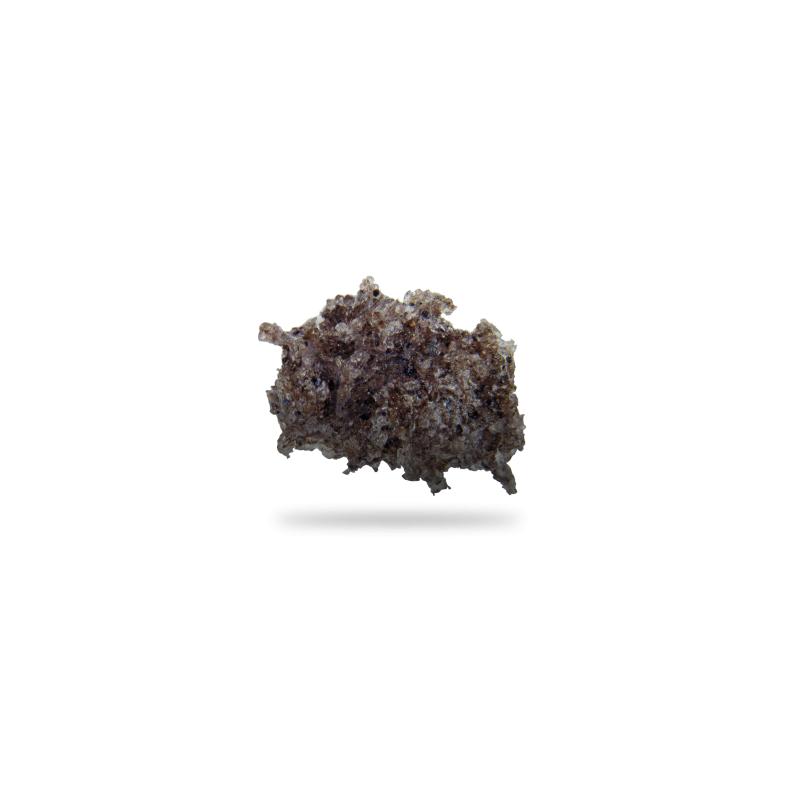

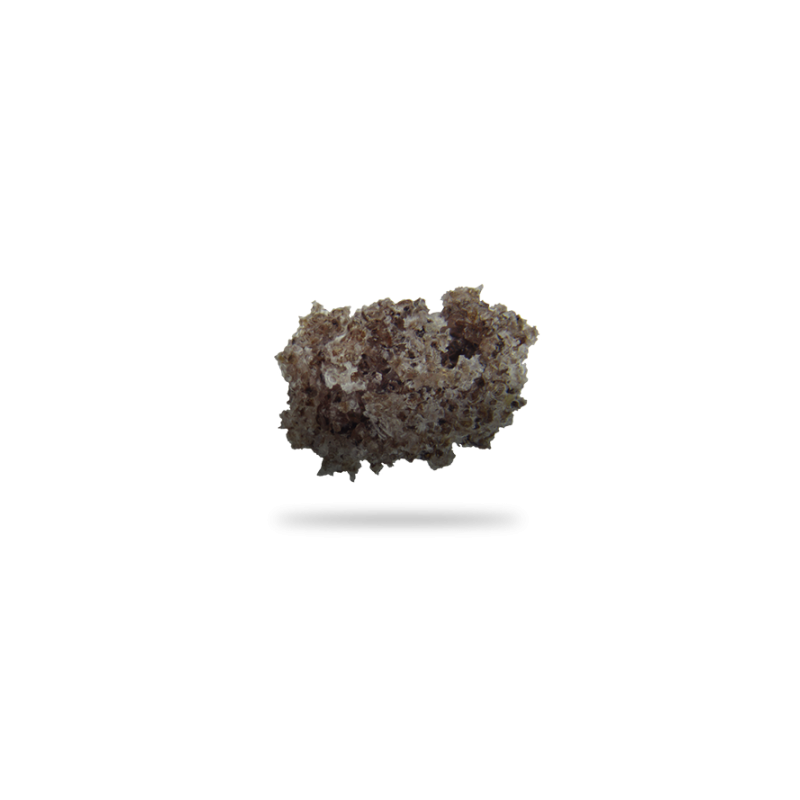

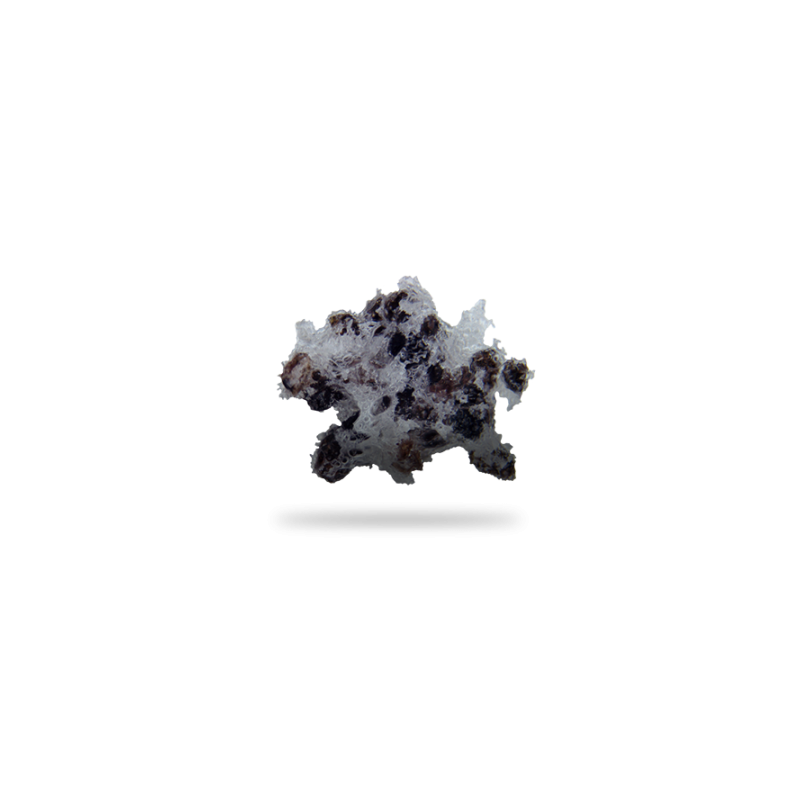

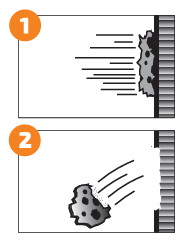

Sponge impregnated with 80-grit Aluminum Oxide to clean or profile metals, concrete and other materials. CARB certified.

Sponge-Jet Abrasive Buying Guide

BlastOne is your one-stop shop for all your surface preparation needs. Sponge-Jet abrasives are a revolutionary alternative to traditional blasting media, offering a gentler touch on delicate surfaces while maintaining exceptional cleaning power.

But with a variety of Sponge-Jet media options available, choosing the right one for your project can be a challenge. This guide will help you navigate the different Sponge-Jet abrasives offered by BlastOne and select the perfect media for your specific application.

My Account

My Account