Industrial Defense & Heavy Equipment Blast & Paint Facilities

Many heavy equipment fabrication facilities are under pressure to reduce costs and improve efficiency. With our blend of experience and advanced technologies, customized to your specific operating requirements, we can rapidly ramp up your productivity and drive down your costs. Through supplying better equipment, better processes and better staff training, BlastOne can partner with you to revolutionize your corrosion control facilities. Our partnership with you will set in motion better outcomes now and in the future.

Heavy equipment needs an impenetrable durable barrier to protect the steel from corrosion. These assets are large investments, and if they become prematurely corroded, impact profitability and reduce productivity.

Abrasive blasting will ensure the surface is ready for quality coating application, which lengthens the lifespan of the coating.

Here are a few common issues we’ve found from working with the industry:

The Best Blasting Equipment

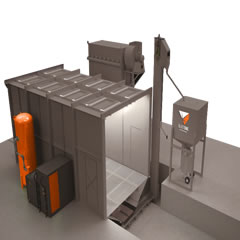

While it is possible in a multiple blaster facility to use multiple one/two man pots around a blast site, a better solution is a bulk blaster. These start at 75 cu.ft. capacity (as opposed to a one /two man pot with 6 to 10 cu.ft.) and go up to 160 cu.ft. capacity. The big efficiency gained here is only filling the blaster once a day. These units can run multiple operators for an entire shift without requiring refilling – no time lost on blow-down, filling and restarting.

A clean surface is the first step to having a quality finish on heavy equipment, trucks or trailers. Abrasive blasting removes dirt, dust, imperfections and unwanted contaminants from the body. White metal surface is an ideal finish for primer and epoxy sealing.

ROBOTS & AUTOMATION

If you wish to increase the output and reduce the costs of your blast and paint facility, if blaster employee turnover is high, or a poor safety record is a concern, BlastOne recommends automated surface preparation systems. Either the robotic manipulator arm style of blasting or wall or gantry mounted machinery can automate your blasting.

ABRASIVE RECOVERY SYSTEMS

Abrasive media is one of the biggest recurring costs for any blasting operator. A single contractor can blast up to 6 tons of abrasive in a single day. The quickest way to save on abrasive cost is recovering and recycling used abrasive.

BlastOne’s oscillating cross conveyor system which has a live sieve on it, efficiently removes coarse trash from the reusable media. The next stage of the cleaning process is the air wash. This passes a curtain of used abrasive across a low-suction extraction system to remove abrasive fines. The system works completely out-of-sight to not interfere with day-to-day operations, with external access to key component parts. It has proven to be efficient and effective, with little-to-no maintenance necessary.

My Account

My Account