ABOUT WAREHOUSE SERVICES

Warehouse Services is a leading provider of steel pallets and industrial storage solutions. They are known for their commitment to quality, durability, and customer satisfaction. With a focus on efficiency and innovation, Warehouse Services has become a trusted partner in the logistics and manufacturing industries, offering products that are built to last and tailored to meet the specific needs of their clients.

PROJECT OBJECTIVE

To meet increasing demand and improve the quality of their steel pallet production, Warehouse Services aimed to enhance their manufacturing capabilities. Their primary objective was to implement a blasting and painting solution that would allow them to improve the surface preparation and finishing of their products, ensuring consistent quality while increasing productivity. The project aimed to achieve an efficient, scalable system that could support future growth.

BACKGROUND

The existing manufacturing setup at Warehouse Services needed an upgrade to integrate in-house blasting and painting processes. These additions were necessary to maintain the company’s high-quality standards and to improve efficiency across production. By incorporating a dedicated blast and paint booth, Warehouse Services intended to streamline their workflow, reduce outsourcing, and better control the quality of surface preparation and finishes.

CHALLENGE

Warehouse Services faced the challenge of integrating both blasting and painting capabilities within their existing facility in a way that would be easy to implement and scalable for future growth. They required a system that could handle the heavy-duty blasting and coating required for steel pallets while ensuring operational efficiency and safety.

SOLUTION

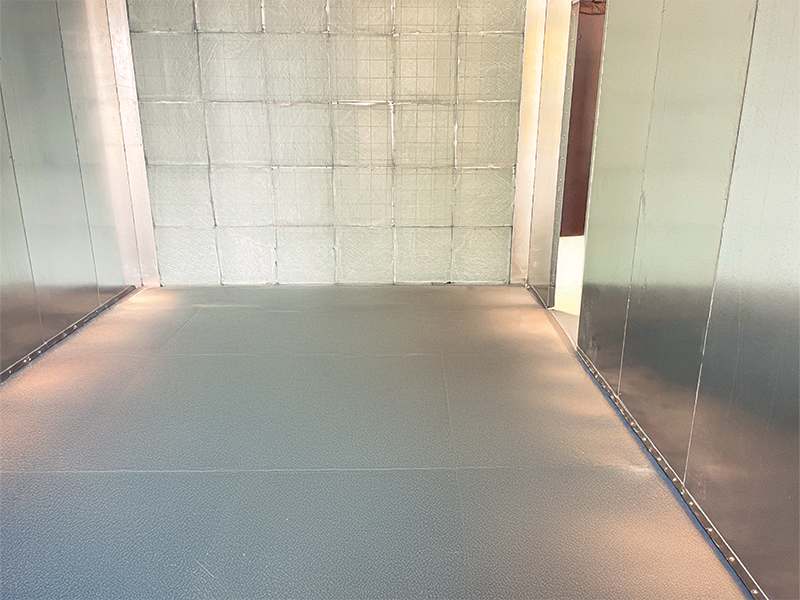

BlastOne provided Warehouse Services with a complete blast and paint booth solution tailored to their needs. The blast booth was constructed with inside dimensions of 12’W x 12’H x 26’L, featuring 2” rock wool insulation for noise reduction, rubber protection on the walls, and a heavy-duty roll-up door. The booth was equipped with ceiling-mounted LED light fixtures with protective covers and safety interlock switches on all doors, ensuring a safe working environment. The full-floor abrasive recovery system incorporated a sweeper-style recovery mechanism, a bucket elevator with a vibrating screen, and an airwash to optimize abrasive reuse, enhancing environmental sustainability and cost-efficiency.

The paint booth was designed with similar dimensions to provide flexibility in the production line, equipped with double-swing product doors, a semi-downdraft ventilation system, and a high-powered blower motor for efficient airflow. The booth was also integrated with a make-up air unit for temperature control, allowing for consistent and high-quality paint application. The paint booth setup included a paint mix room to ensure the proper handling and mixing of paints, further contributing to safety and efficiency.

Both booths were designed to operate independently while ensuring seamless integration into the existing production workflow, minimizing disruptions during installation. The solution also included a dust collection system for the blast booth with an 8,000 CFM cartridge dust collector, auto-pulsing system, and ducting, maintaining air quality and ensuring compliance with safety standards.

RESULTS

With the new blast and paint booths in place, Warehouse Services has significantly enhanced their production capabilities. The integration of these booths has allowed them to complete the surface preparation and finishing of their steel pallets in-house, ensuring a higher level of quality control and consistency across their products. The use of the full-floor abrasive recovery system has not only reduced material waste but also improved operational efficiency, making the production process more environmentally friendly.

The new blasting system has ensured precise and effective removal of rust, mill scale, and surface contaminants, while the paint booth has enabled the quick and consistent application of protective coatings. This combination has led to improved durability of Warehouse Services’ steel pallets, meeting the high-quality standards their clients expect.

Additionally, the upgraded facility has increased the overall throughput of Warehouse Services, allowing them to meet growing demand with ease. The ability to control both blasting and painting in-house has streamlined the production process, reduced dependence on third-party services, and ensured faster project turnaround times.

The investment in these new capabilities has positioned Warehouse Services for future growth, enhancing their ability to serve customers effectively while maintaining the high standards they are known for. This strategic upgrade has provided Warehouse Services with the tools needed to stay competitive in a demanding market, ensuring that they can continue to deliver top-quality products in a timely and cost-effective manner.

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account