OVERVIEW

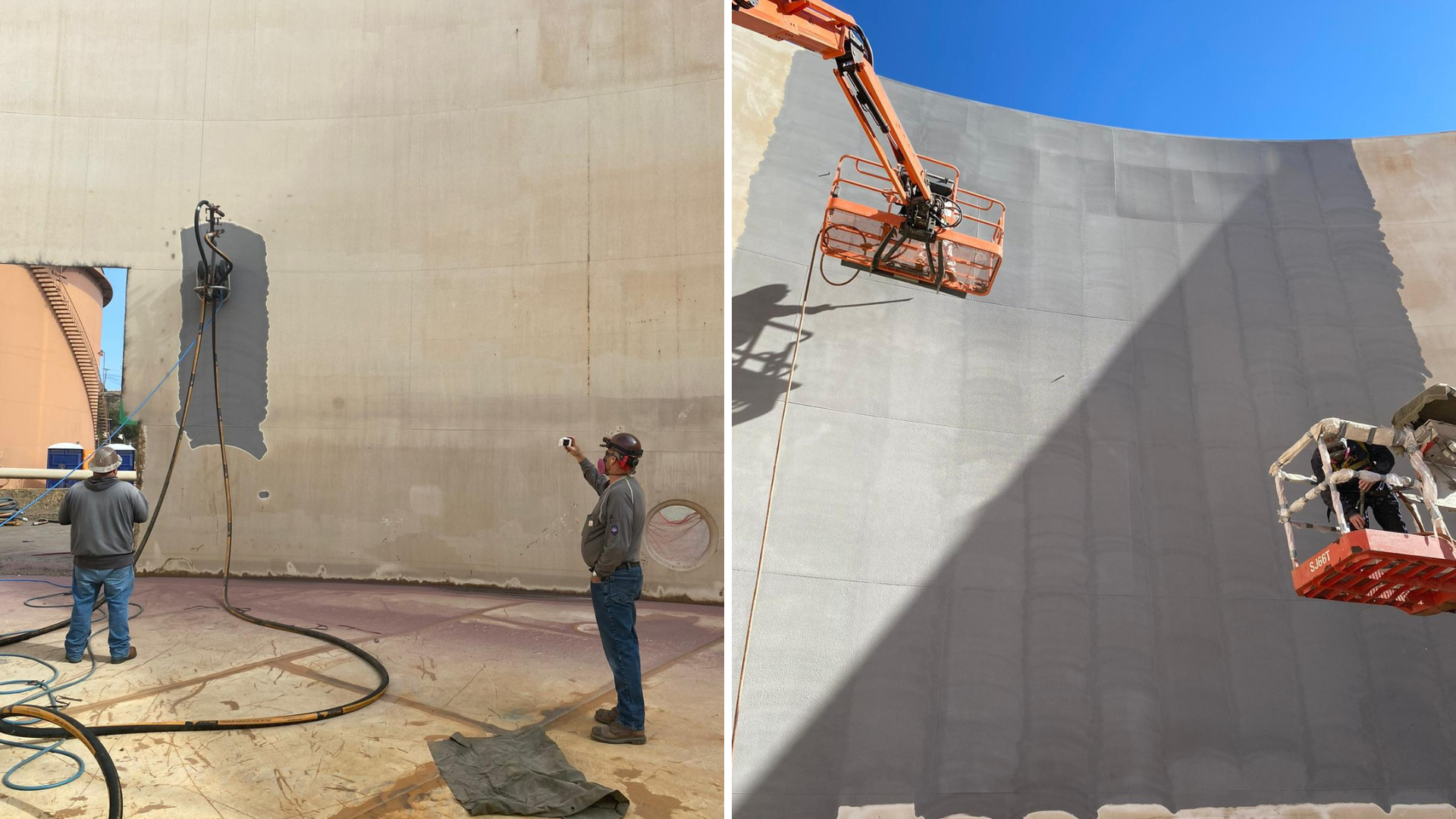

Redwood Painting Co., Inc. recently partnered with BlastOne to utilize the innovative VertiDrive Abrasive Blast Robot on a tank project. This collaboration resulted in significant improvements in project efficiency, cost savings, and overall safety.

So far, this is the second tank we’ve done with the Vertidrive.

And, just by our experience of being blasters and, you know, holding onto nozzles with our hands, there’s really no way we can compete with the Vertidrive.

It literally uses less grit. It’s better on our bodies, all the way around. It’s just a better unit.

I could see it being used a lot more, especially here in the refineries, when we have all these tanks to do.

But as a Redwood Painting employee, we can’t compete with the Vertidrives. They work unbelievably.

– Kurt Passetti, Redwood Painting

CHALLENGES

Traditionally, tank surface preparation involves manual blasting, a labor-intensive process with several drawbacks:

Time-consuming

Manual blasting takes considerable time, impacting project schedulesHigh abrasive consumption

Traditional blasting methods waste a substantial amount of abrasive materialIncreased equipment needs

Manual blasting often requires a larger footprint of on-site equipmentSafety concerns

Manual blasting exposes workers to dust, debris, and potential ergonomic hazards

SOLUTION

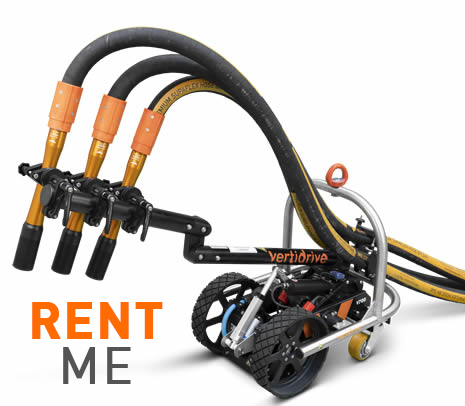

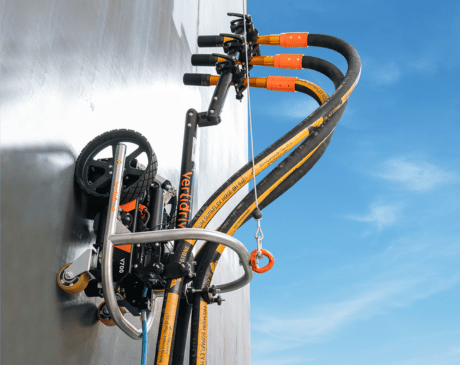

Redwood Painting addressed these challenges by incorporating the VertiDrive Abrasive Blast Robot into their project. The VertiDrive is a magnetically-attached robotic system that automates the abrasive blasting process.

KEY BENEFITS:

Up to 5x more productive compared to manual blasters

Use up to 3 SnakeBite Strike #10 nozzles simultaneously

Automate timing & speed

Blast walls, floors, even upside-down

Wireless control with joy stick

Keeps operators out of harm's way

RESULTS

The VertiDrive delivered impressive results for Redwood Painting:

Reduced Project Timelines

The VertiDrive significantly accelerated the tank surface preparation process, leading to substantial time savings and faster project completion

Reduced Abrasive Consumption

The VertiDrive’s controlled blasting approach minimized abrasive waste, achieving reductions of up to 75% compared to manual methods. This translates to significant cost savings.

Equipment Improvement

By utilizing high efficient equipment, Redwood increased production rates while improving overall project costs.

Enhanced Technical Support

BlastOne provided exceptional on-site technical support, ensuring efficient operation and faster completion.

CONCLUSION

Redwood Painting’s successful implementation of the VertiDrive Abrasive Blast Robot showcases the transformative capabilities of this technology. The VertiDrive demonstrably reduces project timelines, minimizes abrasive consumption, and lowers overall project costs. Additionally, the VertiDrive promotes a safer work environment by eliminating the need for manual blasting operations.

Considering the VertiDrive for Your Projects?

Learn how the VertiDrive Abrasive Blast Robot can streamline your surface preparation projects.

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account