VERTIDRIVE LEADS TO 40% REDUCTION IN LABOR COSTS ON NAVY VESSEL PROJECT

AUSTRALIA

My Account

My Account

Catalog | Locations | Bulk Order | Quote List

In October 2021, Eptec, an industrial service provider, sought our expertise for a project at the Henderson Naval Shipyard in Australia. The challenge was to carefully remove a 7mils [175 microns] top coat of International Intershield 300 from an RAN Navy Vessel. The primary goals were clear: increase productivity, enhance safety, and crucially, reduce labor costs.

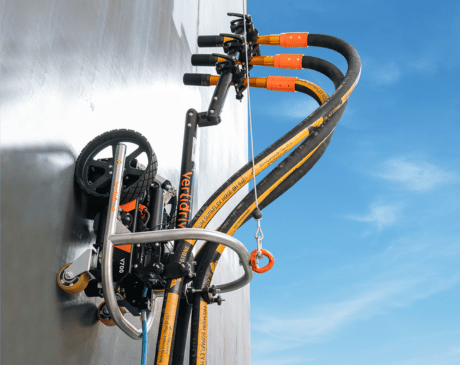

To address these needs, we recommended the VertiDrive, a state-of-the-art abrasive blasting system. The VertiDrive, equipped with 2 #7 Snakebite nozzles, was perfectly suited for this task, effectively removing the top layer while preserving the mid-coat. Protecting the mid-coat was accomplished by reducing the pressure to a careful 90psi at the nozzle. Additionally, an Amphiblast with 1600 air prep, along with GMA PremiumBlast abrasive, ensured a smooth and efficient operation. To provide comprehensive coverage, the set-up included two additional manual blasters on man lifts, focusing on areas requiring intricate detailing.

The results were compelling. The VertiDrive delivered a performance rate of 366 sq ft/hr, marking a significant improvement in productivity. Most notably, the use of the VertiDrive enabled our client to achieve a 40% reduction in labor costs by replacing the need for four blasters and one spotter, with just two blasters and one robot operator.

The results were compelling. The VertiDrive delivered a performance rate of 366 sq ft/hr, marking a significant improvement in productivity. Most notably, the use of the VertiDrive enabled our client to achieve a 40% reduction in labor costs by replacing the need for four blasters and one spotter, with just two blasters and one robot operator.This case highlights how the integration of innovative technology like VertiDrive can lead to significant gains in productivity and safety, as well as substantial reductions in labor costs – a testament to the value and efficiency we strive to deliver to our clients.

Learn how the VertiDrive Abrasive Blast Robot can streamline your surface preparation projects.

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

Registration is required to create a Quote.

Click Here to Login or Register.