Company Overview

BME Services is a global company providing industrial services and equipment across the UK, Europe, the Middle East, and West Africa. Based in Aberdeen, the company offers a wide range of services, including surface preparation and coatings, high-pressure water jetting, industrial wash bay and aftermarket services, NORM decontamination, and RPS survey.

The company was founded by the Borland family, who have over 50 years of experience in the oil & gas and marine industries. With a team of handpicked experts specializing in their fields, BME Services offers a wealth of experience to its clients.

The Challenge

CalMac – Caledonian MacBrayne contracted BME Services to remove a four-layer Jotun epoxy coating system from the top side of the Glen Sannox ferry boat. The Glen Sannox ferry boat had dimensions of 1102 ft x 183 ft (102.4 x 17 meters) and a total area of 21,527.8 ft2 (2,000 m2) Traditional manual blasting methods would have been time-consuming, and working at height could have been unsafe for the operators. The four-layer Jotun epoxy coating system had a thickness of approximately 1,000 microns.

Solution

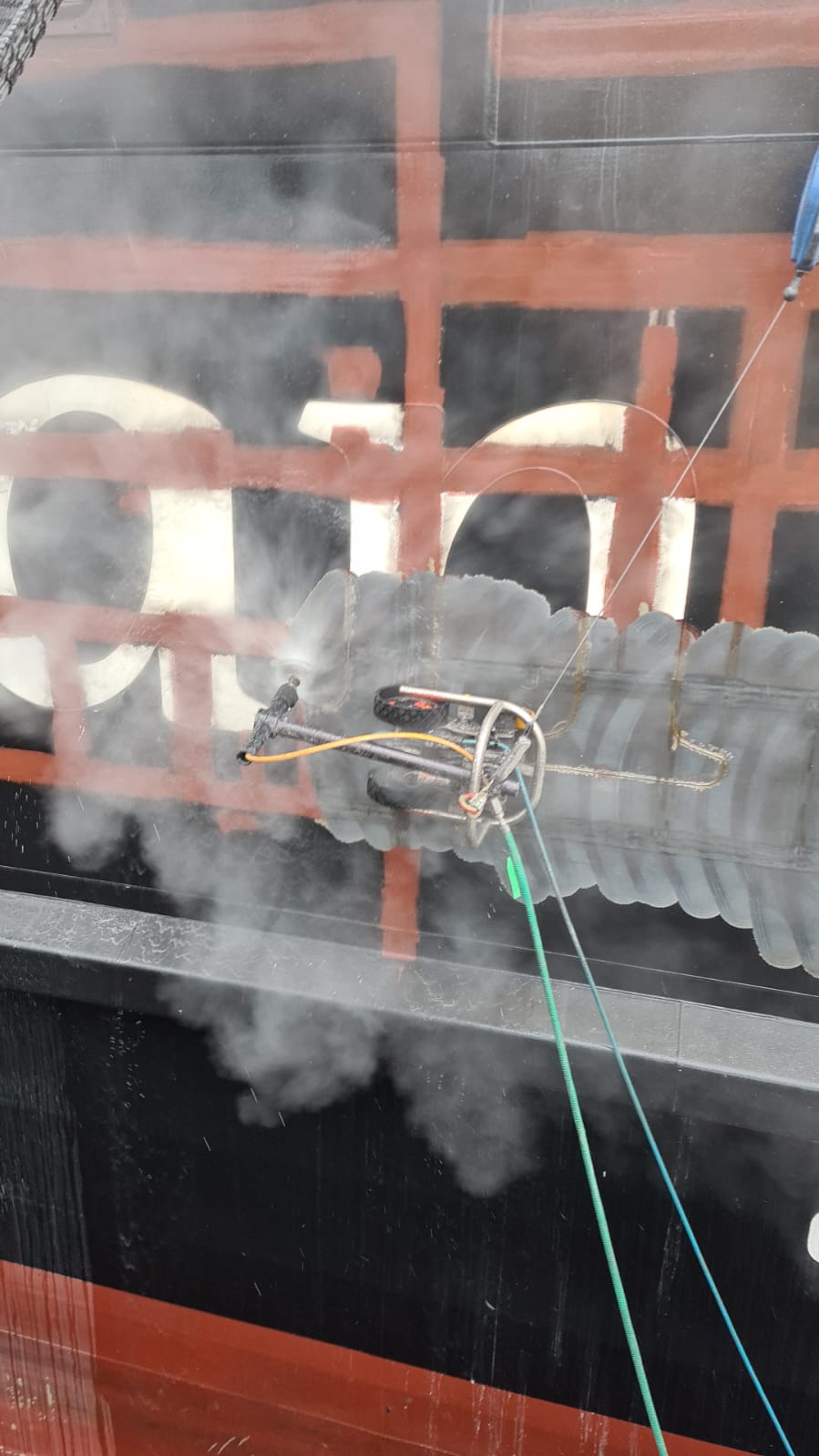

BME Services utilized UHP (ultra-high pressure) water blasting to remove the epoxy coating from the Glen Sannox ferry boat’s top side. BME Services deployed their VertiDrive robot for the UHP water blasting operation as it does not require working at height, making it a safer alternative for operators. For auxiliary equipment, BME used a 2500 Bar UHP pump running at 26 LPM (6.8 gal).

The Results

BME Services successfully completed the Glen Sannox ferry boat’s top-side project within eight days, deploying two staff members for the project, one robot operator, and one pump operator. The use of UHP water blasting and the VertiDrive robot allowed BME Services to complete the project faster, safer, and with consistent quality. An average of 1345.5 ft2/day (125 m2/day) was achieved, considering the inevitable pressure drop of the water as it has to flow all the way to the top side of the boat, it is significantly higher than the 269 ft2/day (25 m2/day) that would have been accomplished using traditional manual blasting methods.

CONCLUSION

This kind of project highlights the importance of expertise and specialized equipment in industrial cleaning operations. BME Services’ ability to utilize UHP water blasting and the VertiDrive allowed them to complete the Glen Sannox ferry project faster and safer than traditional methods.

BME Services’ commitment to safety is evident in their use of robotics and other specialized equipment, which contribute to a safer working environment for their employees.

Overall, BME Services’ success in this project showcases their ability to provide efficient, safe, and high-quality industrial solutions. With their experienced workforce, specialization, and cutting-edge equipment, they are well-equipped to meet the unique needs of their clients.

Considering the VertiDrive for Your Projects?

Learn how the VertiDrive Abrasive Blast Robot can streamline your surface preparation projects.

The M7 in short

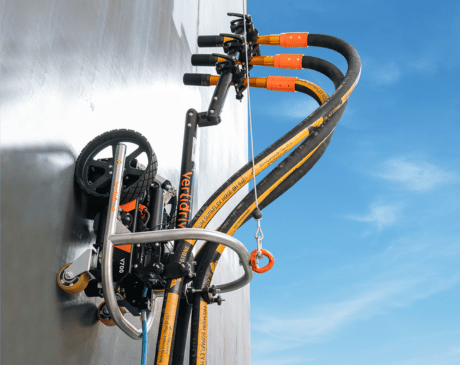

The VertiDrive M7 magnetic crawler provides numerous advantages over traditional manual blasting, regardless of whether you choose UHP water jetting or dry abrasive blasting. Here are some compelling reasons to utilize the M7:

- Versatility: The M7 is a versatile solution that can be utilized for multiple purposes in the steel surface preparation stage, including washing, UHP blasting for de-coating, rust removal, and abrasive blasting. This means that you can use the same robot for various applications, saving you time and money.

- Health and Safety: By using our magnetic crawlers, operators can maintain a safe distance from harmful dust and other toxic particles that are released during manual blasting. Basic personal protective equipment (PPE) are often sufficient. Still, be extra careful and prepared when the jobsite is littered with hoses under high pressures. Additionally, operators won’t have to deal with heavy thrusts from UHP and abrasive blasting nozzles, which can keep your staff healthy and happy.

- Consistent Quality: Our robotic surface preparation solutions enable you to achieve consistent SA or WJ standards every time, satisfying even the most demanding inspectors.

- Increased Production Rates: The M7 magnetic crawler can complete surface preparation tasks at a faster rate than manual blasting. Ultimately, completing your projects faster, resulting in less downtime for the asset owner and provides a competitive edge for the contractor.

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account