Salt, Dust, Chloride Contamination Buying Guide

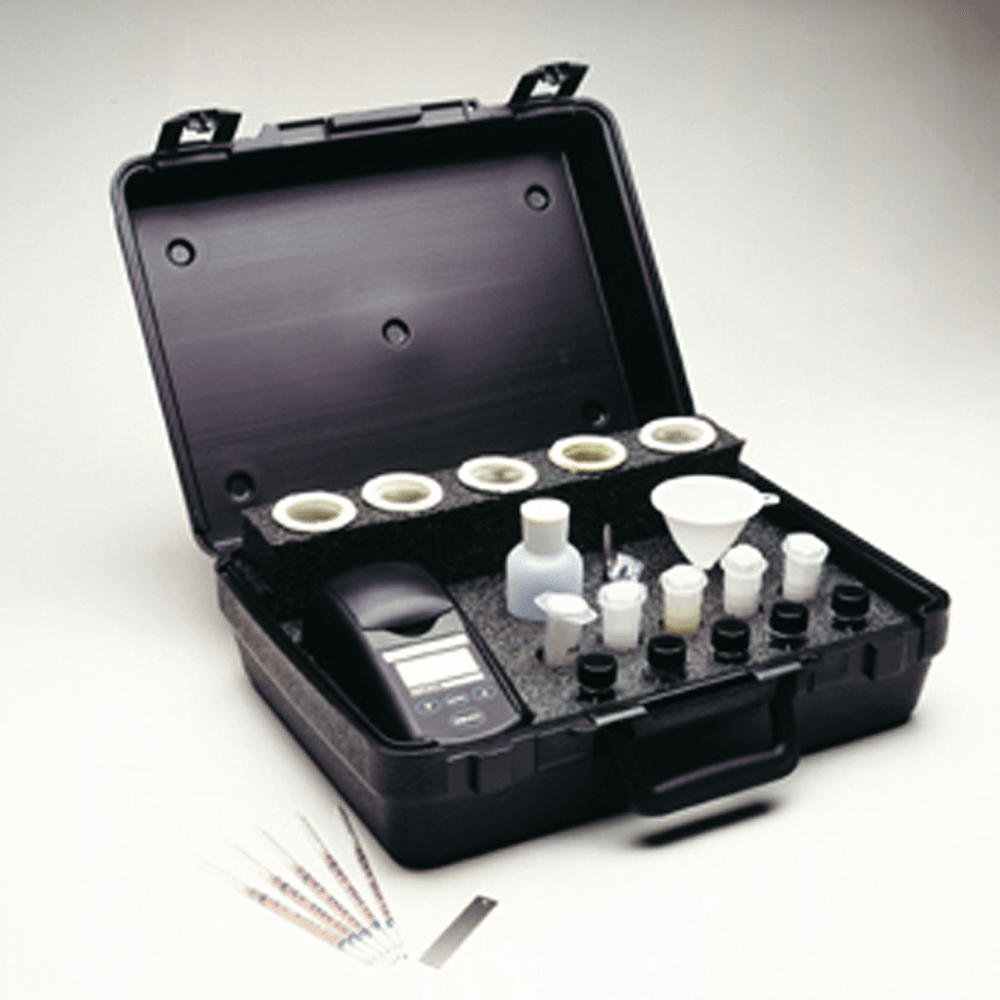

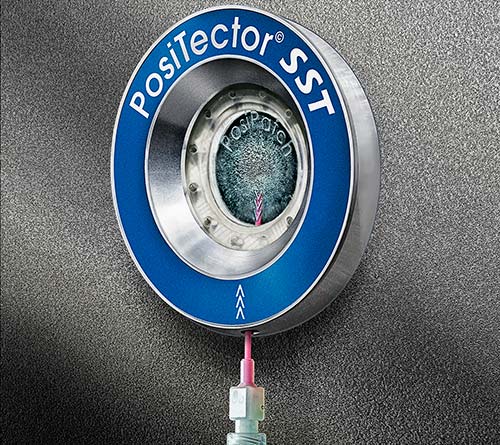

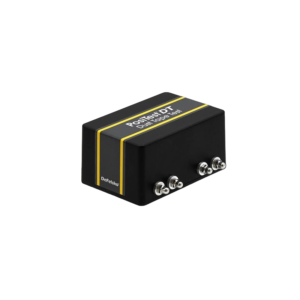

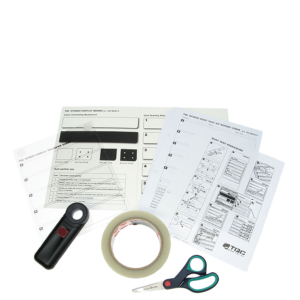

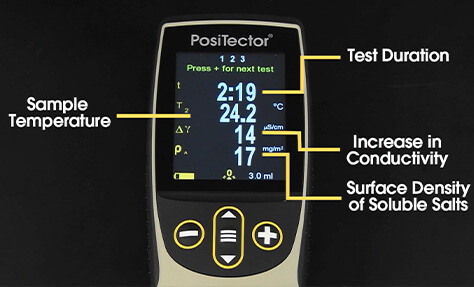

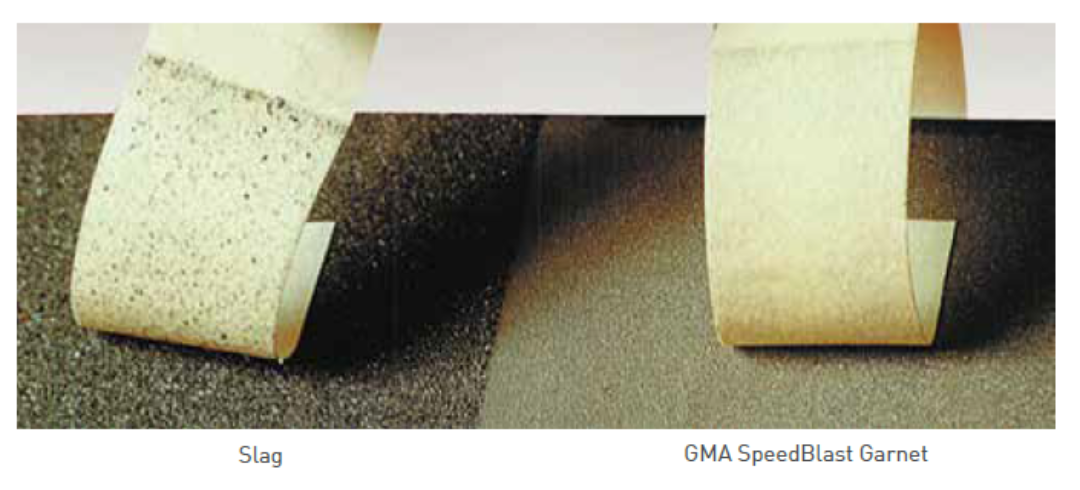

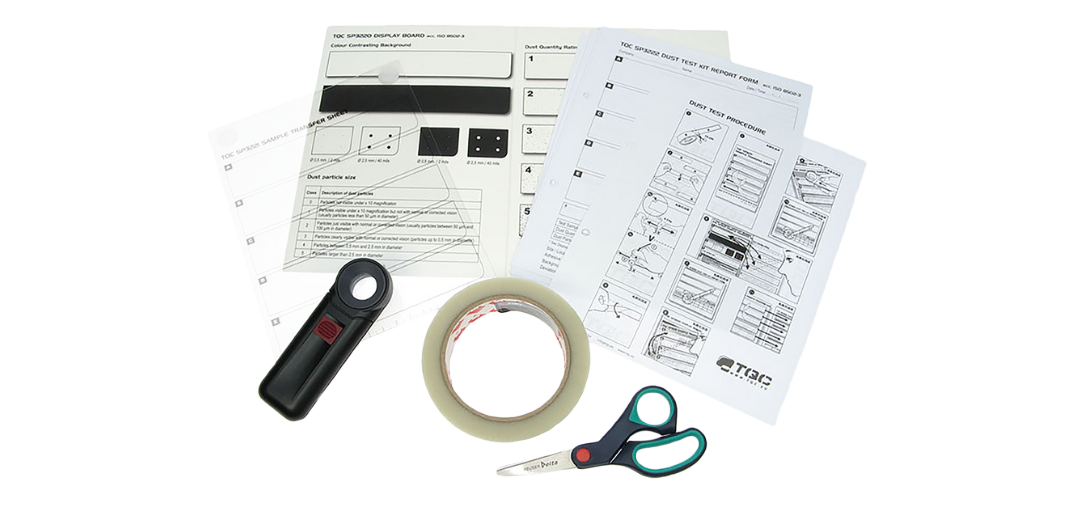

Achieving a flawless, long-lasting finish on steel surfaces starts with a clean foundation. Surface contamination from soluble salts and residual blast media are major factors affecting the long-term performance of coatings on steel surfaces. Before the application of protective coatings, substrates must be thoroughly inspected for the presence of surface contaminants such as soluble salts, dust, oil, and grease. Avoid premature coating failure and costly rework!

Ensure optimal coating performance on your steel projects. This buying guide will help you select the right surface contaminant test kit for your next project.

My Account

My Account