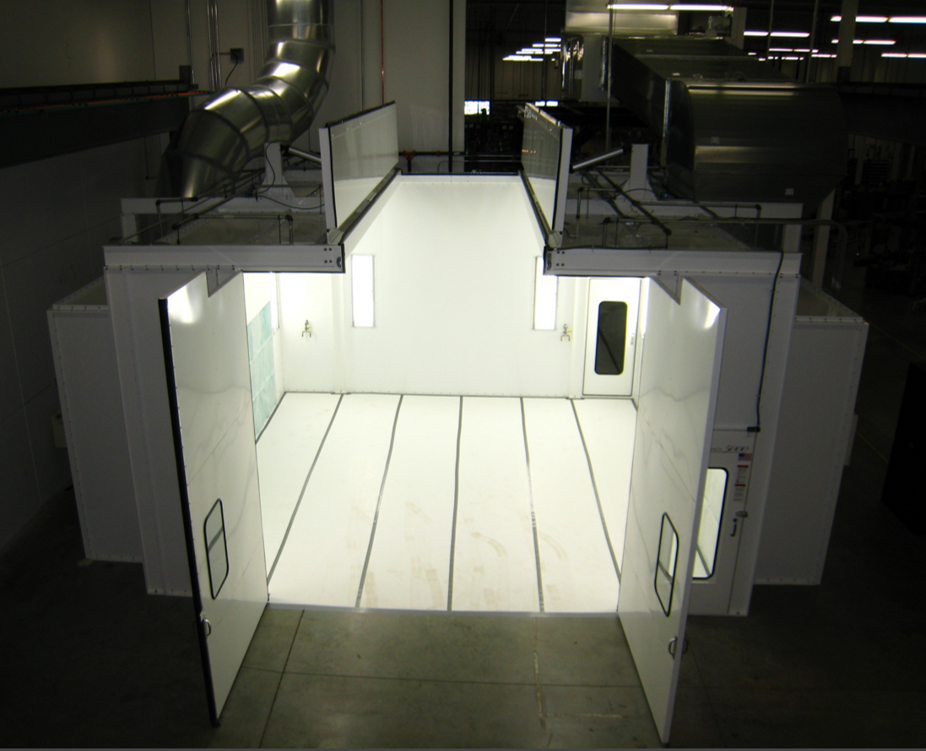

Large Paint Booths

It is now possible to contain the painting operation of the large fabrication or work piece within a controlled booth environment.

Bench Paint Booths

It is now possible to contain the painting operation of the large fabrication or work piece within a controlled booth environment.

Dry Filter Paint Booths

Simply the most economical dry filter paint booths on the market. Maintenance is easy, quick and very low cost.

Enclosed Paint Booths

Enclosed booths greatly increase finish production quality in a simple and effective manner.

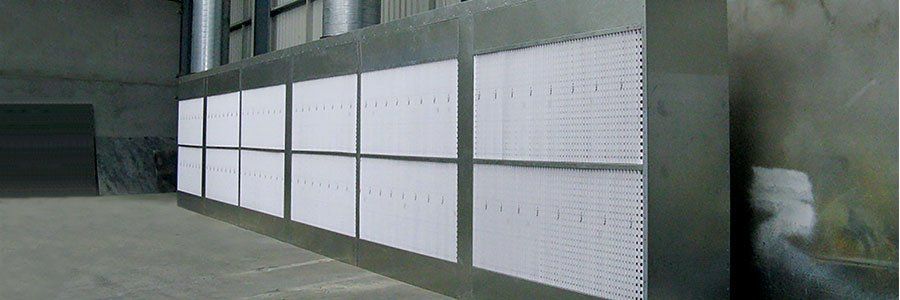

Filter walls

Filter walls range are the ideal solution to ventilating large painting areas or DPA’s. Available in many configurations they work every time.

Open Front Painting Booths

Open front painting booths provide clear access to the spraying work area and contain all fumes and over-spray.

Spray Paint Booth and Bake Ovens

Built for achieving the ultimate finish. This spray booth range allows production to paint in a controlled environment all year round.

Water Wash Booths

The water wash filtration system consists of a 2 stage turbulence module to provide the complete wet and dry particle filter system.

Spray Painting Booths

PAINTING BOOTH SAFETY REGULATIONS

Regulatory authorities now require that any paint spraying operation or manufacturing is carried out in a controlled and contained work area that complies with the respective industry standards and safety requirements.

With the pressure of much-needed environmental and climate preservation, government regulations and increasing work health and safety (WHS) awareness it is a constant concern for many organizations to ensure their processes and spray paint booth facilities are safe and compliant.

BlastOne offers products and services to help you implement or upgrade your spray painting process and ensure you maintain quality, efficiency, and lawful compliance.

PAINT BOOTH – TRUSTED PARTNER

With 40 years of industry experience, BlastOne is a strategic partner to any business seeking greater efficiency and profitability.

By designing, manufacturing and constructing paint facilities for multiple industrial applications – from small bench paint booths to multi-million-dollar combination spray paint booths and blasting facilities. The facilities can be designed to handle small manufacturing parts, right up to large ship and aerospace sections. BlastOne can design and construct any facility to suit your individual application requirements while meeting your deliverable and financial expectations. With a BlastOne coating chamber your business is guaranteed to achieve superior performance and results.

Case Study

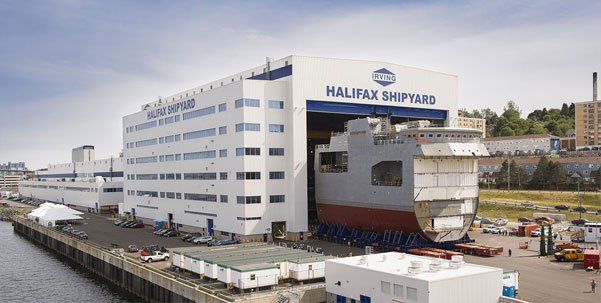

Ship Builder Challenged To Paint 365 Days/Year

OVERVIEW

Headquartered in Halifax, Nova Scotia, Irving Shipbuilding Inc. is a member of the J.D. Irving group of companies, one of Canada’s largest family-owned companies. Irving Shipbuilding was chosen by the Royal Canadian Navy to produce the next class of Canadian Surface Combatant (CSC) and Arctic and Offshore Patrol Ship (AOPS) vessels under Canada’s National Shipbuilding Strategy (NSS).

Irving was faced with a daunting task of building a new facility to produce naval ships under a single roof – including a very large paint facility within the same building.

They sought BlastOne’s expertise.

Talk to the right people

We understand – there are A LOT of questions to be asked when it comes to manufacturing and installing an industrial spray painting booth. BlastOne always offers free consultations to industry professionals. Our goal is to help you implement the best solution for your budget.

My Account

My Account