The World’s Quietest Blast Nozzles

• 45% Less Thrust!

My Account

My Account

Catalog | Locations | Bulk Order | Quote List

Use on your project for 21 days If you decide to keep it, we’ll invoice you. If not, simply return it. No fees at all.

| Name | DELETE | Sizes | Best Scenarios | Benefits | Related Docs | Buy Now | |

|---|---|---|---|---|---|---|---|

|

LPS (Low Pressure Silencer Attachments) | 6 / 7 / 8 | 2” (50mm) Coarse Contractor Thread |

|

|

||

|

SNAKEBITE FLEX | 6 / 7 / 8 | 2” (50mm) Coarse Contractor Thread |

|

|

||

|

SNAKEBITE XQ | 6 / 7 / 8 | 2” (50mm) Coarse Contractor Thread |

|

|

||

|

SNAKEBITE STRIKE | 10 | 2” (50mm) Coarse Contractor Thread |

|

|

|

|

|

|

|

|---|---|---|---|---|

| Name | LPS (Low Pressure Silencer Attachments) | SNAKEBITE FLEX | SNAKEBITE XQ | SNAKEBITE STRIKE |

| Sizes | 6 / 7 / 8 | 6 / 7 / 8 | 6 / 7 / 8 | 10 |

| Thread | 2” (50mm) Coarse Contractor Thread | 2” (50mm) Coarse Contractor Thread | 2” (50mm) Coarse Contractor Thread | 2” (50mm) Coarse Contractor Thread |

| Best Scenarios |

|

|

|

|

| Benefits |

|

|

|

|

| Related Documents | ||||

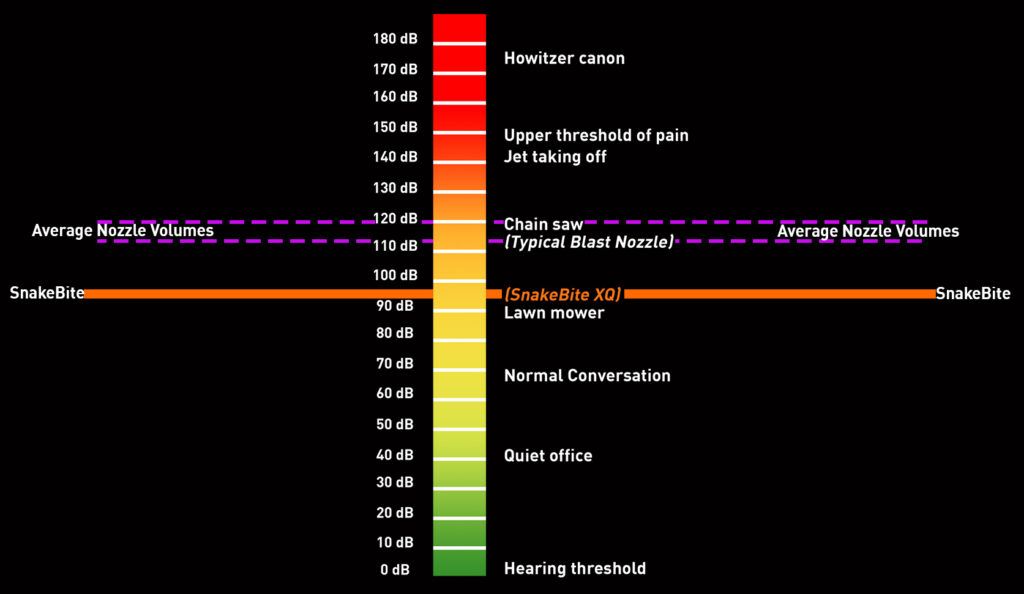

The SnakeBite XQ reduces noise generated by up to 16 dBA – that’s equivalent to up to 75% quieter than standard nozzles, and the typical high pitched screech is now gone.

Reduce the risk of operator and bystander hearing related injuries and increase your ability to comply with workplace noise regulations.

Start blasting operations earlier and finish later with reduced noise impact on noise sensitive areas. Reduce noise related exclusion zones in workshops, areas adjacent to blast rooms and site blasting operations. This will provide increased access and flexibility. Reduce or eliminate sound absorbing barriers when blasting operations are conducted close to noise sensitive

locations.

Lower nozzle thrust reduces operator strain and increases the ability to control the nozzle – reducing the risk of manual handling related injuries and injuries related to loss of nozzle control. Importantly operators will have more energy at the end of the day improving their quality of life.

The unique design of the nozzle and silencer reduces nozzle thrust by up to 45%. Operators can better maneuver the nozzle across the surface and will be less fatigued over the shift and on an ongoing basis – a key factor allowing high cleaning rates to be achieved throughout the shift and project. Nozzle thrust reduces to that of a nozzle two sizes smaller when the silencer is fitted. Using a no. 7 SnakeBite XQ feels like you’re using a standard no. 5 nozzle.

Noise and nozzle thrust reduction occur automatically across a wide range of operating pressures 90-110psi – simply screw on the silencer and away you go. Slimline ergonomic nozzle jacket design reduces operator hand fatigue.

An entirely new operator experience. It feels different, it sounds different – and let’s face it, it looks fantastic! There is no other nozzle like it. The ultimate production tool that delivers contractors and asset owners lower noise, lower operator fatigue and improved project outcomes, ticking the box on the key challenges faced by the blasting industry today.

Recently, BlastOne launched it’s most innovative product to date – The Snakebite XQ – which we claim to be the world’s quietest abrasive blasting nozzle.

That’s a pretty substantial claim and so we’d like to demonstrate how we can defend such a claim.

How loud is 1 decibel?

Volume is not measured on a linear scale like our base-10 number values where “20” is twice as much as “10”. When it comes to decibel levels, “20dB” is ten times louder than “10dB”. That’s because decibel volume is measured on a logarithmic scale – which can be very confusing.

USEFUL COMPARISONS:

10 dB ………………….. Breathing

20 dB ………………….. Whisper, rustling leaves

30 dB ………………….. Quiet rural area

40 dB ………………….. Library background noise

50 dB ………………….. Conversation at home

60 dB ………………….. Conversation in restaurant public area

110-120 dB…………… Abrasive blast nozzle at 100psi

| ULTRA-TUFF NOZZLE | HYPER NOZZLE | SNAKEBITE XQ | |

| 5ft (1m) | 114 dB | 113 dB | 98 dB |

| 25ft 7.5m) | 107 dB | 105 dB | 90 dB |

| 50ft (15m) | 102 dB | 99 dB | 83 dB |

| ULTRA-TUFF NOZZLE | HYPER NOZZLE | |

| 5ft (1m) | Snakebite XQ is approx 62% quieter (16 dB quieter) | Snakebite XQ is approx 62% quieter (15 dB quieter) |

| 25ft (7.5m) | Snakebite XQ is approx 65% quieter (17 dB quieter) | Snakebite XQ is approx 62% quieter (15 dB quieter) |

| 50ft (15m) | Snakebite XQ is approx 75% quieter (19 dB quieter) | Snakebite XQ is approx 62% quieter (16 dB quieter) |

After launching the Snakebite XQ we received more than a few questions regarding a competing quiet nozzle. How is our design different? Is our nozzle quieter than theirs? What differentiates our “quiet nozzle” from the competition?

You can simply look at both nozzles to see our unique design differs from anything else on the market. And it’s our scientific design that produces our amazing results.

We decided to test it against the competing nozzle to determine which was quieter. In this decibel test, we maintained identical set-up and pressure – just over 100psi – and measured the results with a volume meter.

Here is the result:

Although (you’ll notice by watching the video) there were small fluctuations in dB volume for each nozzle as the readings were taken, the median difference was great enough to distinguish a decisive verdict on which nozzle is quieter.

The following image represents the lowest measured dB reading for each nozzle.

Volume Comparison Chart

Until now, when companies needed a high production nozzle to blast acres of steel – they relied on a #8 hyper nozzle. This was the largest nozzle a man could handle for 4-6 hours on any given day.

Some contractors don’t even realize #10 nozzles are an option… and that’s because a #10 exerts far too much thrust for practical, daily blasting. That is… Until now.

The same design technology that reduces both the noise and thrust on our SnakeBite XQ… also makes the Snakebite Strike – the world’s most effortless #10 blast nozzle.

The only caveat is you need to have enough air. Your compressor needs to supply at least 750 cfm per Strike nozzle.

But 54%? Really?

Well to start, here are some simple measurements comparing a single pass of a Snakebite #10 with various other nozzles, including a #8 Hyper.

| Nozzle Size | Single Pass Pattern Height Through Paint | Single Pass Pattern Height Through Flash Rust |

| #6 Hyper | 1.5″ / 3.8cm | 2″ / 5.08cm |

| #7 Hyper | 1.75″ / 4.45cm | 2.25″ / 5.715cm |

| #8 Hyper | 2″ / 5.08cm | 2.5″ / 6.35cm |

| #10 Hyper | 2.25″ / 5.715cm | 3.0-3.25″ / 7.62-8.255cm |

| #10 Snakebite Strike | 2.5″ / 6.35cm | 3.25-3.5″ / 8.255-8.89cm |

During a recent visit to the United States, BlastOne CEO, Matthew Rowland, sat down to discuss various questions about the SnakeBite XQ and how it benefits the blasting industry.

QUESTION:

Matthew, so not only are you the CEO but you’re an actual engineer, you understand the science of the nozzle, and I was hoping that you might be able to shed some light on the development and what causes this nozzle to be so much quieter than a typical nozzle?

ANSWER:

That’s a great question. With BlastOne, we’ve invested heavily in looking at ways to improve the blasting environment for our workers and operators. So one of the common complaints we get from our customers is that blasting is dusty, it’s noisy, it’s dirty. What we’re looking for is technology that changes that environment for them – makes it safer, simpler, and easier… and hence more productive in the work that they have to do. So what we did is, we went back to first principles to really understand how a blast nozzle works, and how those processes within that nozzle generates the abrasive flow and also a by-product generating noise.

A little known fact is that less than 10% of the energy used in a blasting environment is actually beneficially used in blasting.

So that means that there’s more than 90% of the energy that’s used in the compressed air and the abrasive that is wasted.

And a lot of that wasted energy creates noise. So what we did was look at how do we develop a silenced nozzle.

We’re not the first company that’s tried to do this but what we have come up with is a revolutionary way to reduce the noise and maintain the productivity of blasting.

So we’re really excited by this technology development and the silencer is very effective in a wide range of operating conditions and we’re really hoping that our customers have a great experience using it.

QUESTION:

So does BlastOne expect this will replace the standard blast nozzles out there?

ANSWER:

No.

This nozzle is great for applications where you need lower noise.

So in those environments where you’ve got nearby neighbors… you’ve got other trades working… that you need to reduce noise this is where it’s ideally suited.

If you’re just after productivity at the lowest cost this isn’t the nozzle for you. It is designed to be used in areas where you need to reduce noise.

QUESTION:

There have been a few comments on social media comparing the SnakeBite to other quiet nozzles out there competing nozzles – and they’re basically asking us if we copied those designs.

And can you just clear up any confusion about that?

ANSWER:

We’re not the first quiet nozzle… but we’re the world’s quietest blast nozzle.

But the reality is that our industry has been trying for decades to come up with a quieter way to blast, and there are other technologies and we really look forward to the whole industry improving the reduction of noise in blasting. We went back to first principles and we engaged a university – the Center of Hypersonics at the University of Queensland, and we redesigned the whole process of the blast nozzle and the silencer that we use so it’s a very unique design but delivers outstanding results but based on fundamental research.

So… there was no copying involved in that design.

QUESTION:

Can you discuss the nozzles reduction in thrust?

ANSWER:

When we developed SnakeBite our primary goal was to reduce the noise of blasting.

As we’re developing this technology we also identified a way to reduce the thrust of the blast nozzle while maintaining the abrasive energy. So allowing the same productivity but as a significantly lower noise level. We’re really excited that it’s got a lower thrust because what that does is it reduces the fatigue on the operator and allows them to work longer not only in their the day but also for their career.

So they’re not being injured and they’re not experiencing those high forces that really takes a toll on their body… so people are keen to stay longer in their careers of blasting.

QUESTION:

And finally, the price is pretty steep compared to a standard abrasive blast nozzle can you shed some light onto the reasons why? I mean, maybe explain its value?

ANSWER:

Yeah great question… when we developed this product we’re really focused on the feedback from our customers who are finding it more and more challenging to blast in environments

where noise was an issue.

So increased complaints from nearby trades… from community near the blast site… and that was costing our customers significant money. So they’re either having to reduce their hours… take people off site… so we see that this technology can deliver outstanding value for our customers. We had a customer recently who had a blast room and also five workers doing other fabrication nearby and for every hour that the blasting occurred those eight workers had to go off site because it was too noisy for them to continue to work.

With the introduction of SnakeBite those eight workers could continue working in the same area and be productive.

And we estimate that the customer saved over $30,000 per week by having that work continue during blasting. The other way to look at it is in terms of the cost of health.

What is the cost of hearing? So it might be $2k-10k dollars for a hearing aid but what’s the cost of a blaster or someone else working in that environment whose hearing is damaged that can’t be replaced? We think the cost of that is much greater.

And the other one is it’s just safer you know when people are blasting in difficult environments on a bridge or other situations rather than having to fight a hose with such thrust it’s much lower through half the thrust so they’re much safer than they’re less likely to be pushed off or put in a dangerous situation.

At BlastOne we are really passionate about the safety and health of our customers and we continue to invest in technologies that makes life not only more productive but safer and more enjoyable.

So… SnakeBite’s a new technology and we’re really excited with a number of new technologies that we’ll also be bringing to market that will further improve the health and safety of our customers.

Productivity of the Flex is comparable with standard nozzles (same size, pressure, media) and the XQ is up to 25% more productive than standard nozzles of the same size. The reduced nozzle kick-back thrust – up to 45% – can actually increase productivity by reducing operator fatigue and enabling a high rate of productivity to continue throughout the shift…. and the #10 Strike (due to the larger orifice size) can increase hand-held blasting productivity up to 54%.

Adjusting these factors will have an effect on dB reduction.

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

Registration is required to create a Quote.

Click Here to Login or Register.