COMPANY PROFILE

Hitachi is a worldwide manufacturer of construction machinery, specializing in manufacturing dump trucks, excavators and wheel loaders. Believing in reliable solutions, Hitachi prides itself in providing the best experience and technology in the construction machinery industry.

OBJECTIVE

In Perth WA, Hitachi’s manufacturing space had a blastroom for blasting new and used machinery components nearby a team of 5-6 fabricators and welders. After a recent OH&S visit, Hitachi was advised that the fabrication and welding teams could no longer occupy the area while the blasting operation was active.

The cost of blasting became extraordinary. Every time the blasting started, the other workers had to leave the area. The cost per hour of blasting increased

SOLUTION

After BlastOne presented the Snakebite XQ, Weir Minerals conducted a third party, independent study to determine whether the Snakebite would reduce the blasting noise enough to allow the blastroom to stay inside the production facility.

Jack Hart was on-site to conduct the trial for BlastOne and these observations were from a third party OH&S contractor brought in to be an impartial observer.

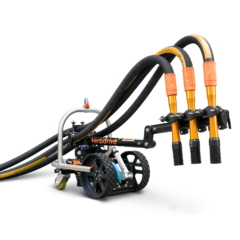

BlastOne introduced the Snakebite XQ Blast Nozzle to the team at Hitachi, which reduced the sound pollution from the blasting operation by 17dBA, reducing noise pollution by 75%. As a result, those 6 fabrication workers could continue working in the same area while blasting occurred. Hitachi estimated that they saved over $30,000/week by having their working continue during blasting.

RESULTS

The Snakebite XQ is the worlds quietest blast nozzle. Designed and manufactured by BlastOne, this product effectively reduces the noise pollution of blasting by 75% and also reduces the operator fatigue up.

NOISE REDUCTION – SnakeBite XQ reduced noise levels by 17 dBA for Hitachi. That’s equivalent to more than 75% quieter than standard nozzles and the typical high pitched screech is now gone.

PRODUCTION COSTS – With reduced noise levels, the 6 fabrication workers could return to work during blasting, which saved Hitachi over $30,000/week.

EASE OF USE – The unique design of nozzle and silencer reduces operator fatigue by up to 45%. Operators can better maneuver the nozzle and will be less fatigued over the shift.

CONCLUSION

By implementing the new OH&S recommendation, blasting hours increased while halting production for fabricators and welders. This production workflow disruption cost up to $30,000/week for Hitachi.

With the help of SnakeBite XQ, Hitachi reduced work site noise by 75%, which met current OH&S standards. SnakeBite XQ reduces noise by up to 17 dBA and saved Hitachi thousands of dollars in the process.

Experience the BENEFITS

THAN TUNGSTEN CARBIDE NOZZLES

THE SNAKEBITE DIFFERENCE

An entirely new operator experience. It feels different, it sounds different – and let’s face it, it looks fantastic! There is no other nozzle like it. The ultimate production tool that delivers contractors and asset owners lower noise, lower operator fatigue and improved project outcomes, ticking the box on the key challenges faced by the blasting industry today.

The SnakeBite XQ (Extra Quiet) Blast Nozzle

SnakeBite XQ – The World’s Quietest Blast Nozzle

A SNAKEBITE NOZZLE FOR EVERY APPLICATION

Frequently Asked Questions

Does the reduced thrust compromise productivity compared to standard nozzles?

Productivity of the Flex is comparable with standard nozzles (same size, pressure, media) and the XQ is up to 25% more productive than standard nozzles of the same size. The reduced nozzle kick-back thrust – up to 45% – can actually increase productivity by reducing operator fatigue and enabling a high rate of productivity to continue throughout the shift…. and the #10 Strike (due to the larger orifice size) can increase hand-held blasting productivity up to 54%.

Is 1.25`` hose with a 750cfm compressor sufficient when using the SnakeBite Strike?

It depends on hose length. It is not recommended to use the Strike with a 1.25″ hose longer than 25 feet.Do I need any special equipment to get the SnakeBite noise and thrust reduction?

No, just screw the SnakeBite with the Silencer fitted into a contractor thread nozzle holder, set the pressure to 100psi and start blasting. Blasting noise will automatically be reduced by up to 16 dB and and you will immediately feel around 45% less nozzle thrust – there is nothing else you have to do.What if my nozzle isn't achieving a reduction of 16 dB?

Factors contributing to the optimal reduction in sound pollution include.- Nozzle pressure needs to be between 80-115 psi

- Blasting with lean abrasive flow increases noise

Adjusting these factors will have an effect on dB reduction.

How long will the nozzle last?

Expected wear-life for the SnakeBite is over 800 hours. This is 4x the life of a standard tungsten carbide nozzle.

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account