CHALLENGE

After a massive fire rampaged through downtown, the only salvageable structure was a severely damaged parking garage. The parking garage was immense, totaling seven stories. Each level of the garage was over a hectare of space. The four stories underground suffered water damage, while the three stories above ground had smoke damage. Every square inch of the steel in the garage would need to be re-blasted, painted, and fire-proofed.

Due to its location in the heart of downtown and proximity to a nearby hotel, the blasting attracted a lot of attention. The contractors received a torrent of complaints from neighbors, hotel guests, and nearby workers in the district.

The blasting noise penetrated the bustling business district and the contractors searched for a reasonable solution for the noise pollution.

THE SILENCER SOLUTION

The contractors reviewed many options for deadening the noise of the blasting nozzles, including sound blankets that would hang around the work area, sound deadening containment, plyboard, etc.

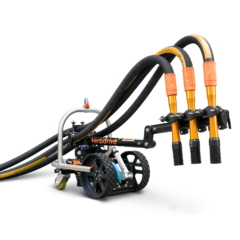

In discussion with BlastOne, the contractors decided that the Snakebite XQ blast nozzle was the best option. The impact was immense. The Snakebite XQ is the world’s quietest blast nozzle and effectively reduced the noise of blasting in the garage and surrounding area by 75%. Now the noise of the compressor, which can be reduced with a sound blanket, is louder than the blasting!

RESULTS

The Snakebite XQ has revolutionized the tireless work needed to revitalize the city district. No longer are the contractors receiving daily complaints about the noise and the crews can now blast at all hours of the day, maximizing productivity. With the help of SnakeBite XQ, the project could potentially begin its operations ahead of schedule and host international guests sooner.

PROJECT TIMELINES – With reduced noise levels, blasting crews could now blast all hours of the day, increasing the efficiency of restoration of the parking garage.

CONCLUSION

In order to reduce noise levels, this contractor needed a timely and efficient solution. Due to the durable, lightweight Silicon Nitride nozzle and silencer liner, the SnakeBite XQ allowed this restoration to begin quietly and safely.

Not only were the numbers of complaints reduced, but the contractor was able to save on production costs since project deadlines were no longer put on hold.

Experience the BENEFITS

THAN TUNGSTEN CARBIDE NOZZLES

THE SNAKEBITE DIFFERENCE

An entirely new operator experience. It feels different, it sounds different – and let’s face it, it looks fantastic! There is no other nozzle like it. The ultimate production tool that delivers contractors and asset owners lower noise, lower operator fatigue and improved project outcomes, ticking the box on the key challenges faced by the blasting industry today.

The SnakeBite XQ (Extra Quiet) Blast Nozzle

SnakeBite XQ – The World’s Quietest Blast Nozzle

A SNAKEBITE NOZZLE FOR EVERY APPLICATION

Frequently Asked Questions

Does the reduced thrust compromise productivity compared to standard nozzles?

Productivity of the Flex is comparable with standard nozzles (same size, pressure, media) and the XQ is up to 25% more productive than standard nozzles of the same size. The reduced nozzle kick-back thrust – up to 45% – can actually increase productivity by reducing operator fatigue and enabling a high rate of productivity to continue throughout the shift…. and the #10 Strike (due to the larger orifice size) can increase hand-held blasting productivity up to 54%.

Is 1.25`` hose with a 750cfm compressor sufficient when using the SnakeBite Strike?

It depends on hose length. It is not recommended to use the Strike with a 1.25″ hose longer than 25 feet.Do I need any special equipment to get the SnakeBite noise and thrust reduction?

No, just screw the SnakeBite with the Silencer fitted into a contractor thread nozzle holder, set the pressure to 100psi and start blasting. Blasting noise will automatically be reduced by up to 16 dB and and you will immediately feel around 45% less nozzle thrust – there is nothing else you have to do.What if my nozzle isn't achieving a reduction of 16 dB?

Factors contributing to the optimal reduction in sound pollution include.- Nozzle pressure needs to be between 80-115 psi

- Blasting with lean abrasive flow increases noise

Adjusting these factors will have an effect on dB reduction.

How long will the nozzle last?

Expected wear-life for the SnakeBite is over 800 hours. This is 4x the life of a standard tungsten carbide nozzle.

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account