Comprehensive Rail Solutions

BlastOne’s provides innovative technologies, and proven methodologies to overcome the common challenges faced by our customers – making industrial surface preparation Faster, Safer and Cleaner.

Whether you are building a new facility for tank car lining, building new hopper cars or trying to upgrade an old facility, we have a solution for you. The tank lining business has been an early adopter of robotic blasting technology and BlastOne is leading that change.

Blast and Paint Facility Design

RAIL BLAST AND PAINT BOOTH APPLICATIONS

BlastOne designs facilities to meet the unique challenges of the rail industry:

Hopper Car Facility

Blast Room with Robotic Blast Arm

Paint Facility with Aquatec – Fast Curing Technology

Blast Room with Vacuum System for Recovering Abrasive

Blast Facility with Man-lifts

THE PROCESS TO A GREAT OUTCOME

As most companies only build a blast and paint facility once in their lifetime, we have designed a streamlined process that guides you to an ultimate solution, fitting both your needs and budget. Too often people engage an engineering company or a friend-of-a-friend to specify what they need, before contracting companies for a 20ft x 80ft facility that oftentimes won’t suit their long-term needs.

This industry is small and very niche and we follow a Design | Bid | Build methodology. Our process has been perfected over decades and begins with a thorough assessment of your facility’s requirements, followed by detailed planning and design before construction.

A deep dive into our Approach and What to Expect

BlastOne delivers high-performance, cost-effective blasting and painting facilities through integrated design, construction, and long-term support. From concept to completion, we tailor solutions to client needs, reducing risks and streamlining processes. With 45+ years of expertise, we provide ongoing support, including maintenance, training, and readily available consumables, ensuring reliability throughout the facility’s life cycle.

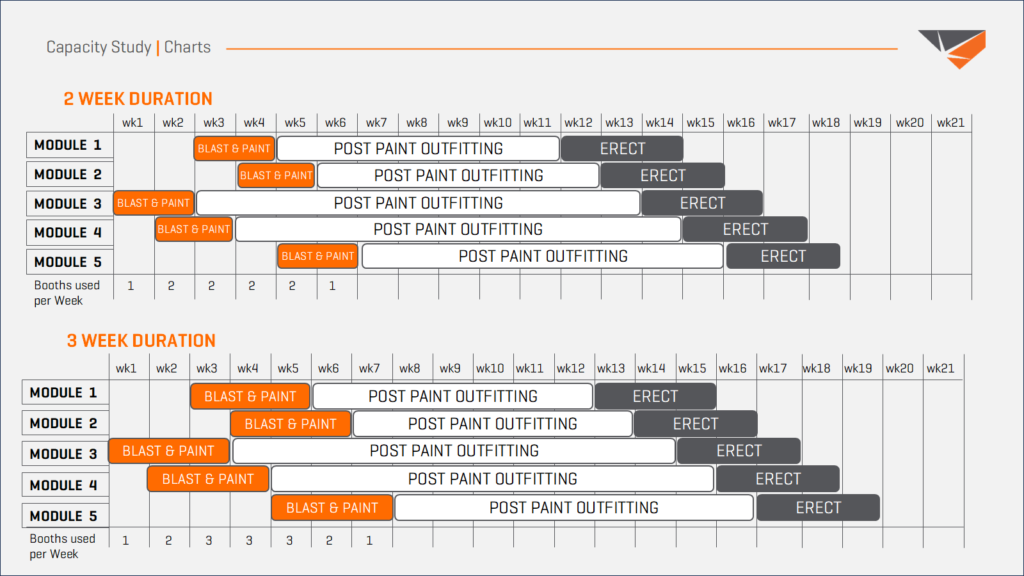

BUILDING THE WORLD’S MOST PRODUCTIVE RAILCAR FACILITY STARTS WITH A CAPACITY STUDY

The BlastOne team would like to take you on a forward-thinking journey to systematically review your production schedules, cycle times, and growth capacity to ensure the facility you build is suited for your growth.

Capacity Studies are designed to review and validate the production capacity you need long term. Throughout the process we assess the efficiency of the proposed blasting and painting operations and identify potential bottlenecks. These studies dictate the size, quantity and functionality of the solution that we would build for you.

Key Components of Capacity Studies:

-

-

-

Workflow Assessment

A thorough evaluation of current processes to identify inefficiencies.

-

-

-

Bottleneck Identification

Detection of areas that impede productivity.

-

-

-

Implementation of Solutions

Application of targeted improvements tailored to specific operational needs.

-

-

Sustained Efficiency

Development of strategies to ensure long-term operational gains.

-

START YOUR JOURNEY WITH A PHONE CALL.

Connect with a professional today.

Robotic Solutions For Rail

Railcar Refurbishing

Blastman B20CX Animation

Robot Blasting Freight Cars

Customized Abrasive Blasting Solutions

Shot Blasting Robot of Railcars

Ongoing Support & Training

SPARE PARTS AND ONGOING SUPPLIES

-

Abrasive

-

Blast Equipment

-

Blast Helmets

-

Paint Equipment

-

Paint Sundries

-

Coveralls and Suits

-

Robotic Parts

-

Inspection/QA

-

Hand Tools

-

Lighting

-

Silenced Blast Nozzles

-

Safety & PPE

BLASTSHIELD MAINTENANCE SERVICES

BLASTSHIELD ACADEMY

-

-

2-Day Equipment Maintenance Course

Covers fundamental equipment upkeep, including blasting operations, reclaim system maintenance, and dust collector servicing.

-

-

-

3-Day Equipment & Robotic Maintenance Course

Adds advanced training on automation systems, robotics troubleshooting, and spare parts management.

-

KEEP YOUR EQUIPMENT RUNNING AT PEAK PERFORMANCE

Enhance performance and longevity with expert services, training, and available spare parts.

Case Studies

LEADING RAILCAR REPAIR SHOP – RETROFITS LARGE VACUUM UNIT TO EXISTING RECOVERY SYSTEM

A leading railcar repair shop improved its grit recovery system by integrating a second 100HP vacuum unit, preventing system backups and enhancing efficiency. BlastOne’s custom solution optimized recovery, reduced downtime, and delivered long-term cost savings.

EMERGING RAILCAR MANUFACTURER TACKLES POTENTIAL BOTTLENECK IN FINISHING DIVISION

To overcome bottlenecks in its finishing division, Vertex Rail implemented automated Blastman robotics, a manual blast booth, a downdraft paint booth, and a high-temperature cure booth. This solution streamlined production, increased efficiency, and significantly reduced labor costs, enabling high-volume railcar output.

— Vertex Rail

ENHANCING RAILCAR REFURBISHMENT WITH ROBOTIC BLASTING

To enhance efficiency and minimize downtime, a leading railcar service provider replaced its outdated wheel blasting system with a state-of-the-art robotic blast room. The transition began with a manual blasting setup, ensuring continuous production until robotic components were installed. This upgrade increased productivity, reduced costs, and improved blast quality and consistency, providing a significant competitive advantage.

Real Solutions. Real Impact.

See the Results!

Industry & Project Challenges

All railcars, whether it is a closed top hopper car, box car, tanker car, or auto-rack, can fall victim to coating failure.

Some common issues we’ve found from working with the industry:

-

-

-

Confined spaces and working at heights

Working inside or outside a rail or tank car can be hazardous. While blasting the interior of the car, the space is extremely cramped and difficult to move within. Coupled with this are all the hazards of a confined space – toxic substances, flammable gases, lack of oxygen, difficulty of evacuation/extraction. While blasting the exterior, the operator is often working at precarious heights. This decreases maneuverability and at the same time creates a fall risk.

-

-

-

Unable to meet project deadlines

Variations in coating types between cars means production can be greatly impacted, leading to scheduling delays. Additionally, areas of the cars may need to be repaired before blasting can begin. Depending on the extent of damage, this can disrupt the project workflow.

-

-

-

Strict quality control and regulations

The variety of coatings used on each railcar results in major variations in surface profile requirements. This makes quality control a challenging task. Consequently, a rail car facility needs to have a suitably qualified coating inspector onsite, checking quality standards compliance constantly.

-

-

Safety concerns

The range of hazards in a rail car blast and paint facility is extensive – some general hazards found in most engineering facilities, and some specific to blasting and painting. BlastOne is able to supply both corrosion control industry-specific PPE and general PPE.

-

Rail Resources

25 Important Considerations when Building a Blast Facility

If you are purchasing a turnkey blast room for building it yourself, there are 25 subjects you need to be well versed in. BlastOne has compiled a detailed report containing an in-depth guide on all the critical components of a blast room: design considerations, abrasive education, and production techniques.

Knowledge & Learning

Videos from the Experts

How to | Primed Insights | Safety Tips

The Difference Between Grinding VS Blasting

Top Producing Blast Booths Have These Features

Myths about Robotic Abrasive Blasting

Industries Served

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account