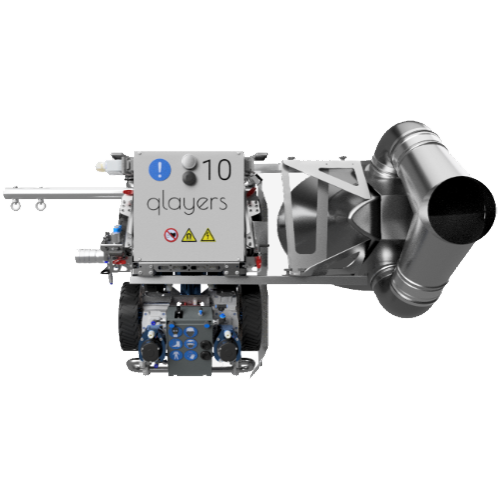

"The 10Q robot test was carried out on a tank of D 42m X H 18m located at the Exolum plant in Torrejón de Ardoz, Spain. The test took two days (implementation and painting) and covered an area of 187 m2 on the outer surface of the tank. We had a very good impression and a great experience working with the Qlayers team. Our feeling was that the progress was faster than expected.

The main advantages are application with an airless gun, therefore, a higher quality, reduction of the hours dedicated to working at height (although not 100%), higher performance than with manual application methods and conservation of the environment by not emitting vapours into the atmosphere due to the ventilation system of the robot. It is a much more advanced method than the current ones and, of course, recommended. I believe that the future of coating application is already here.”

Jose Antonio San Jose Dominguez

Business Unit Manager, Alttion

"My first impression of the 10Q robot (in Louisiana) was that It was very refined and well thought out. The complete equipment spread was very well done, well put together and they did a great job with the compact set up. I think the benefits that any robotics, especially this robot is that it helps the constraints we currently have with labour force that we’re all experiencing here in the US. You’re removing personnel from the job site (dangerous heights) so it definitely helps with that aspect first of all.

In the long run, I think you’ll have the opportunity to cover more projects each year because you’re able to get them done faster and cheaper which is the benefit of the robot in general."

Brady Deroche

COO, Innovative Surface Prep

“Partner Industrial and Qlayers came together and successfully completed the first Qlayers 10Q robotic coatings application in the United States. Partner Industrial was hired by a global energy company to blast, prime, and coat a large liquid storage tank, and we utilized the Qlayers 10Q robot to assist with the coatings portion of the project.

The speed of the 10Q significantly outperformed traditional means of accomplishing this coatings application, while greatly reducing our safety risk by minimizing the amount of exposure our workers had at higher altitudes. Furthermore, the Qlayers robot and technology allowed us to control and eliminate overspray and reduce the amount of wasted paint typically seen on this type of project.

Overall, the 10Q performed exceptionally well, exceeding our expectations as well as the expectations of our customer. Working with the Qlayers team was seamless as they shared our vision for innovation and productivity improvement. They provide excellent technology and service and are an outstanding partner for us. We are proud to be the first to bring their technology to the United States and look forward to continuing our relationship with Qlayers.”

Doug Brittain

Sr Vice President, Partner Industrial LP

“Shell has been working with Qlayers and Van Der Ende Steel protectors in deploying the first industry-accepted and commercial available coating robot for storage tanks. Qlayers’ 10Q robot neatly fits our robotics roadmap since we believe that using robotics for inspection, maintenance and repair activities have the power to fundamentally improve our ways of working.

In April 2021, the 10Q robot was deployed for the first time at our Oil Import Terminal in Europoort. At Shell, as the first large asset owners to successfully deploy Qlayers’ technology commercially, we are proud to mark a next milestone in further improving safety and productivity in our operations. This achievement would not have been possible without the innovative power and entrepreneurial mindset from Qlayers.”

Erwin van Loonen

Maintenance Robotics Program Lead, Shell

“Maasvlakte Olie Terminal as an organisation does have a strong focus on the preservation of the environment and is always searching for improvements and good initiatives to prevent people and the environment from being exposed to toxic wastes and extreme physical conditions. The coating process is currently done manually with rollers in man baskets. Painters are exposed to heavy physical work in difficult conditions, working on heights and painting 3x 5700 m2 by hand. An automated solution would, therefore, be beneficial for people and the environment.

As one of the first in line, Maasvlakte Olie Terminal proposed to execute pilots with the coating robot at their premises initially on some smaller tanks. This was done in 2020. The pilot was reasonably successful despite the expected challenges of working in the field. However, development went on, and several trials were carried out on other terminals before Qlayers returned to Maasvlakte Olie Terminal in 2021. They showed an impressive improvement compared to the previous year. The operating speed had increased, and a minimum number of coating deficiencies were found.

The process was carefully followed up by some of the MOT shareholders as well to full satisfaction. The operating speed, environmental and physical advantages meeting the required quality standards will definitely play an important role in the decision-making process regarding future coating applications on tanks at Maasvlakte Olie Terminal.”

Peter Kassels

Manager Assets and Projects, Maasvlakte Olie Terminal NV

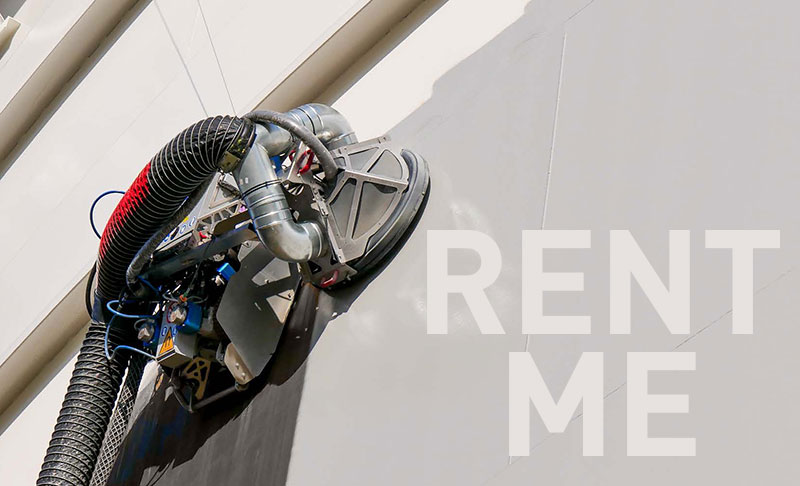

“On the 22nd of September 2021, I witnessed the first application trail on the Hidden Gem from Allseas with a spraying robot from Qlayers at Damen shipyard Schiedam. The trail with the robot on the vessel was very impressive.

The speed of the spraying robot was faster than expected, and the coat which was applied was a nice, even, and closed layer.

Another very big advantage was that due to a very good working extraction system, no overspray was noted during the application. In most of the shipyards in the Netherlands, it’s not allowed to carry out a spray-paint application when the wind is in the wrong direction.

In my opinion, the 7CS robot can be a solution to this issue. Of course, the system is still in the development phase, but I am sure that in the future, we will hear and work a lot more from/with the Qlayers robot!””

Hugo van Roon

Technical Service & Specification Specialist, AkzoNobel

“Braspenning Coatings BV is a blasting and coatings company in the field of ship repair. We are active at various shipyards in Europe. We blast and coat ships in the docks, and we have been doing this for more than 65 years. We tested Qlayers’ robot on the Hidden Gem on September 22. I think that the robot will provide solutions for the overspray problem in the longer term and that we can work greener, which will reduce paint and solvent consumption.

Using Qlayers’ robot in the short term will be good to further develop the robot and, at the same time, show that we are working on solving the overspray and contamination problems. So it is clear that we are doing everything we can to work greener."

Heino Braspenning

Owner & Director, Braspenning Group

“As one of the AkzoNobel Paint the Future Challenge winners, Qlayers’ coating application technology can offer our customers a reduction of coating waste, asset downtime and increased safety; all are key objectives we drive in the industries AkzoNobel is active in. Qlayers’ solution and AkzoNobel’s coating products have been optimized to work together and ensure unparalleled application efficiency with the trusted protection performance of AkzoNobel’s International Paint products. Together, we transform the Paints & Coatings industry towards a new frontier of efficient and sustainable coating application and protection; together, we paint the future.”

Menno van der Zalm

Global Director Innovation, AkzoNobel

“Together with Qlayers, we have executed a second full-scale field test on a real paid-for project by customer MOT. It is clear to us that automation of our processes is valued by our customers because it significantly reduces various risks that come with working with people and is relatively beneficial to the environment. Because the 10Q robot improves on safety, quality, emissions of coating into the environment, and efficiency at roughly the same cost, our customers are rather enthusiastic about the progress we have made so far.

I firmly believe that it is of great value to our company to keep improving our processes and systems because, in the long run, this focus will improve our competitiveness in both the customer market and the jobs market. Besides the fact that the 10Q is a great technical development, what really stands out to me is the agility of the Qlayers team to work around issues that arise during the various stages of development.

It takes a lot of courage, trust, and the right attitude to let go of ideas and designs that have consumed much time, funds and effort earlier on in the development process. A team with these kinds of traits and their engineering skills, in my opinion, is capable of delivering great products where others will fail."

Edgar van der Ende

Commercial Director, Van der Ende Steel Protectors Group

My Account

My Account