Velocity™ System

BlastOne’s Velocity™ System is a novel and game-changing advancement designed to be quickly integrated into high-pressure production environments, alleviating short term blast and coat bottlenecks. This innovative system is specifically engineered to address these bottlenecks efficiently in supplier production settings. The Velocity™ System is a patent-pending integration of advanced technologies proprietary to BlastOne. Each technology offers sustained advantages on its own, but when combined, they act as a force multiplier, delivering exponential results.

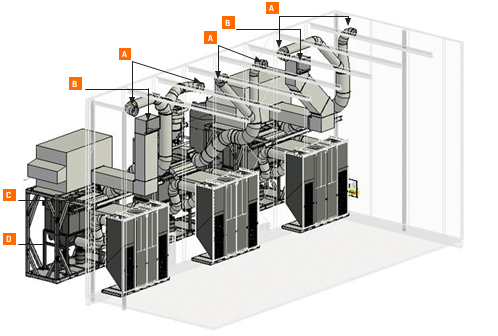

EQUIPMENT SUMMARY

EXTERIOR VIEW

-

-

AVelocity Building (customizable)

-

-

-

BLarge Product Doors

-

-

-

CSkid Mounted Dust Collector with Skid Mounted Dual-Exhaust Plenums

-

-

-

DSkid Mounted Controlled Fresh Air Supply (CFAS) Units for Climate Control

-

-

-

EConnection Blast Pots with Intelliblast Control System

-

-

-

FAbrasive Storage Hopper

-

-

-

GAbrasive Vacuum with Double Dump and Sound Attenuation

-

-

-

HLED Lighting

-

-

-

IProcess Equipment Control Systems and Ducting

-

-

JAll associated Consumables Required to Start Operations

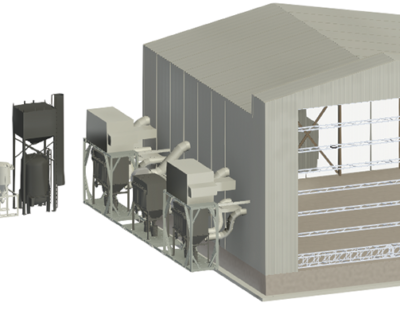

INTERIOR VIEW

-

-

ADust Collector Blower Return Duct

-

-

-

BCFAS Duct

-

-

-

CPaint Exhaust Duct

-

COMPONENTS & KEY FEATURES

This system is tailored for rapid deployment in high-stress environments, offering seamless integration that elevates both productivity and sustainability.

-

-

-

Intelliblast Blast Pot Controls

Smart controls that optimize blasting parameters for maximum efficiency and effectiveness.

-

-

-

Snakebite Blasting Nozzles

High-performance nozzles designed for precise and powerful material removal, reducing blasting time and lowering process noise.

-

-

-

Rapidly Deployable Containments

Innovative containment systems that can be quickly deployed, ensuring a controlled environment, and minimizing the spread of contaminants.

-

-

-

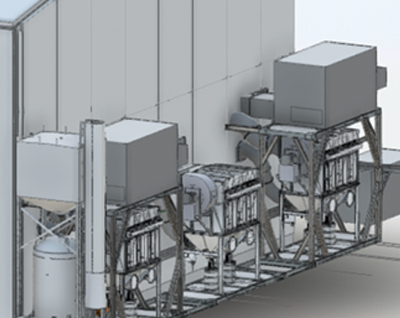

Vortex Airflow Movement

Proprietary airflow design that lowers energy consumption, enhances ventilation, and ensures the efficient removal of particles from the blasting and painting areas.

-

-

-

Combination Dual Air Plenums

Dual air plenums that provide a uniform and controlled airflow, optimizing the blasting and painting processes.

-

-

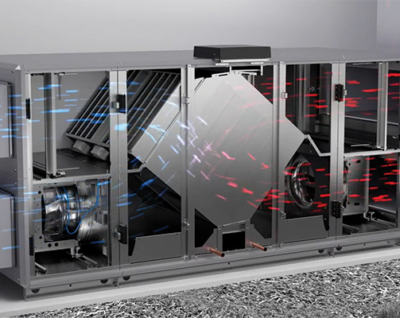

Energy Recovery System (ERS)

An energy recovery system that captures and recycles heat energy, reducing overall energy consumption and operational costs.

-

Intelliblast Blast Pot Controls

Snakebit Blasting Nozzles

Rapidly Deployable Containments

Vortex Airflow Movement

Combination Dual Air Plenums

Energy Recovery Systems

STEPS TO INSTALLATION

Delivery to the Jobsite

The wall panels and roofing are delivered, assembled and folded.

Opening of the Panels

The sections are unfolded with the help of light lifting equipment.

Installation on the Foundation

The four-panel section is placed on the foundation. Only 48 hours are needed to install the six sections of a 40 ft x 60 ft (12 m x 18 m) building.

Securing of the Panels

The panels are bolted together, and the knee braces are attached to the panel framing.

Finishing the Building

At the end of the first day, all the sections will be installed. The second day will be used to finish assembling the panels, including the ones at both extremities. Then, the joints will be sealed and the finishing sheets will be installed (three to four days).

Outfitting the Building

Once the building is complete, time is then needed to place equipment, run lighting, set up ductwork and hosing, and install the controls system. This will be set to be pre-manufactured where possible and then field finished where necessary.

My Account

My Account