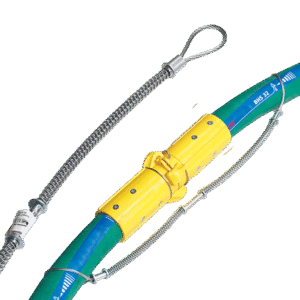

Threaded Blast Quick Couplings

Sku: P-HFTC

The Threaded Blast Quick Couplings (SKU: P-HFTC) provide a durable and efficient solution for connecting metering valve outlets to blast hoses in abrasive blasting operations. These threaded couplings are available in two configurations—Standard and MegaMax—to meet diverse blasting requirements, from standard applications to high-production setups.

MegaMax couplings are designed with a full-flow configuration, eliminating air restrictions commonly found in Standard couplings. This results in increased PSI delivered to the blast nozzle, making them ideal for heavy-duty tasks involving 1.5" or 2" ID blast hoses. Note that adapters are required to connect Standard and MegaMax couplings.

Each coupling is made with high-quality materials, including Aluminum, Brass, Steel, and Nylon, to suit various environments. Couplings are supplied with industry-standard gaskets: HFGMRLP gasket for Aluminum, Brass, and Steel couplings. HFGPCG gasket for Nylon couplings, which also feature an integral springlock pin for added security.

Key Specifications and Benefits:

- Industry-referenced sizes: SB1, SB2, SB-1, SB-2.

- Threaded design ensures a tight, leak-proof connection with proper thread sealant or tape application.

- MegaMax couplers (HFATCMX) are supplied with large bore HF GMRX gaskets and are ideal for blast hoses with bores greater than 1 1/4" (32mm).

- Additional gaskets can be used to maintain a seal if threads do not meet the flange face.

- Regular inspection of gaskets and couplings ensures operational efficiency and safety.

- Lock pins (HF CLP-1, HF CLP-2) and whipchecks must be used to prevent accidents.

Important Notes:

- These threaded couplings are intended for metering valve outlets only. For unthreaded quick-coupling options, refer to the unthreaded QC couplings available on our product page.

- 1 1/4" threaded couplings can also function as quick-couple nozzle holders for fine thread nozzles.

By ensuring airtight connections and secure installations, these couplings reduce turbulence and wear, enhancing the overall lifespan of your blasting system and boosting productivity.

My Account

My Account