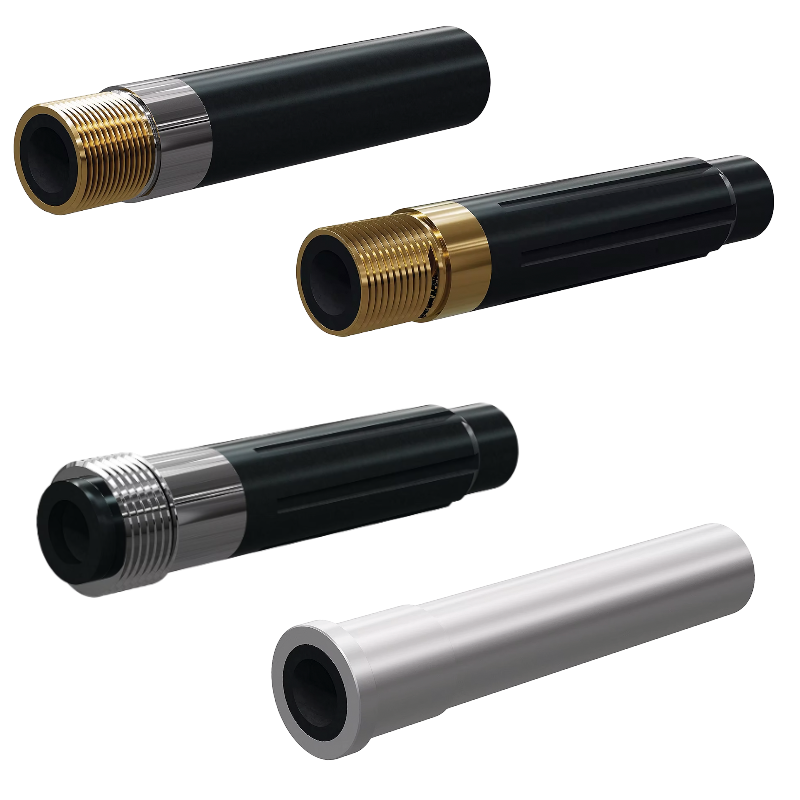

Kennametal TVP Tungsten Carbide Blast Nozzle

Sku: P-BNTVP

The Kennametal TVP Tungsten Carbide Blast Nozzle (SKU: P-BNTVP) combines cost-effectiveness with reliable performance, making it a trusted choice for industrial abrasive blasting projects. Engineered with a venturi design, this nozzle improves abrasive velocity by up to 40% compared to straight-bore models, increasing production rates while delivering a consistent blast pattern. The robust tungsten carbide liner extends its wear life to 200-500 hours, reducing replacement costs and downtime.

Key Features and Benefits:

- Venturi Design:

- The long venturi-style construction optimizes abrasive speed and dispersion for more efficient surface preparation, minimizing time and labor requirements.

- Thread Options:

- 1-1/4″ NPSM Brass Threads: Fine threading ensures a secure fit and compatibility with standard nozzle holders.

- 2″ Aluminum Contractor Threads: Lightweight and durable, ideal for professional setups.

- Flange Type: Unthreaded flange nozzle connects via a standard blast hose quick coupling for enhanced flexibility.

- Orifice Sizes:

- Contractor and fine-thread nozzles available in #3, #4, #5, #6, #7, #8, #10, and #12.

- Flanged nozzles available in #6, #7, #8, #10, and #12.

- Construction and Materials:

- Tungsten Carbide Liner: Provides exceptional durability for extended usage, far outlasting disposable nozzles.

- Jacket Options:

- Polyurethane jackets for contractor and fine-thread nozzles offer lightweight impact protection.

- Aluminum jackets for flanged nozzles provide rugged durability for heavy-duty applications.

- Throat Entry Sizes:

- 1″ (25mm) for #3 and #4 nozzles.

- 1-1/4″ (32mm) for #5 through #12 nozzles.

- Cost-Effective and Versatile:

- As the lowest up-front cost nozzle option, the Kennametal TVP is ideal for general-purpose abrasive blasting. For users seeking extended lifespan, reduced weight, or higher performance, premium nozzle alternatives are available.

Maintenance Tip:

- To maintain optimal blasting performance, replace the nozzle when its orifice wears to the next size larger. Regular replacement ensures consistent abrasive pressure and efficiency, saving time and reducing costs over the long term.

Upgrade Recommendation:

- Consider the Ultra-Tuff Blast Nozzle for up to double the lifespan and 50% less weight compared to standard tungsten carbide nozzles.

My Account

My Account