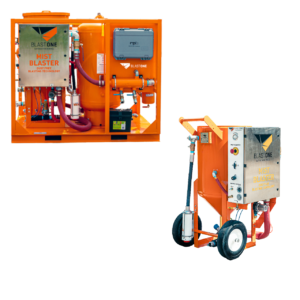

Schmidt / Axxiom Abrasive Blasters (Small Pots)

Sku: P-BMSSMALLPOTS

Schmidt / Axxiom Abrasive Blasters are designed to provide maximum control, productivity, and customization for a wide range of abrasive blasting applications. From small-scale jobs to large industrial projects, these blasters offer precise abrasive metering, efficient pressure systems, and versatile configurations to meet the specific demands of every job. State-of-the-art abrasive metering valves are the heart of all Schmidt Blast Pots, which include the following options:- MicroValve 3® (aka Combo/Micro or MV3) with excellent flow control in Pressure-Release applications

- Thompson® Valve II - the legendary valve created by Schmidt for high levels of control in pressure-hold systems.

- TeraValve XL - the latest offering from Schmidt, offering extended life and an economical, compact design for pressure-hold machines.

- 0.9 cu. ft. MiniBlaster Package

- Ideal for small-scale, detail-focused blasting jobs where portability is paramount.

- Standard package comes with:

- TeraValve Pressure-Hold technology

- Pneumatic G3 Trigger Compact BAABS deadman

- Manual pop-up

- ¾" Piping

- Blaster package with 25' blast hose & twinline and #2 ceramic nozzle, and screen.

- MPN: 8023-010

- 1.5 cu. ft. Blaster Package

- Another popular option for small-scale blasting work and/or projects where portability is critical, and where a larger abrasive tank is desireable.

- Pressure-Release package comes with:

- Portable w/wheels

- ComboValve® & 1-1/4" MicroValve 3® (aka Combo/Micro)

- Pneumatic G3 Trigger Compact BAABS deadman w/55' twinline control hose

- Moisture separator

- 1" Piping (VBS muffler not standard in this size)

- MPN: 6001-011-01

- Pressure-Hold package comes with:

- Same as above except with 1" TeraValve and 1"Auto Air valve instead of Combo/Micro

- MPN: 6003-011-01

- 3.5 cu. ft. Blaster Package

- A versatile option with more productivity and capacity than the smallest units with more portability than the 6.5 and larger sizes.

- Pressure-Release package comes with:

- Portable configuration w/wheels OR Stationary w/Load Skid

- ComboValve® & 1-1/4" MicroValve 3® (aka Combo/Micro)

- Pneumatic G3 Trigger Compact BAABS deadman w/55' twinline control hose

- Moisture Separator

- VBS II industrial muffler

- 1-1/4" Piping

- MPN: 6001-031-01 Portable w/wheels

- MPN: 6001-031-01L Stationary w/Load Skid

- Pressure-Hold package comes with:

- Same as above except with 1-1/4" TeraValve and 1-1/4" Auto Air valve instead of Combo/Micro

- MPN: 6003-031-01 Portable w/wheels

- MPN: 6003-031-01L Stationary w/Load Skid

- 6.5 cu. ft. Blaster

- The most commonly-used size. Maintains good portability while offering more abrasive capacity for longer blasting runs between abrasive refills. Suitable for contractors and industrial blast room applications.

- Pressure-Release package comes with:

- Portable configuration w/wheels OR Stationary w/Load Skid

- ComboValve® & 1-1/2" MicroValve 3® (aka Combo/Micro)

- Pneumatic G3 Trigger Compact BAABS deadman w/55' twinline control hose

- Moisture Separator

- VBS II industrial muffler

- 1-1/2" Piping

- MPN: 6001-061-01 Portable w/wheels

- MPN: 6001-061-01L Stationary w/Load Skid

- Pressure-Hold package comes with:

- Same as above except with 1-1/2" TeraValve and 1-1/2" Auto Air valve instead of Combo/Micro

- MPN: 6003-061-01 Portable w/wheels

- MPN: 6003-061-01L Stationary w/Load Skid

- 6.5 cu. ft. Axxiom Contractor Package

- Similar to the standard Portable w/wheels, Pressure-Hold Blaster Package, but with the following changes:

- Thompson II valve instead of TeraValve

- Includes Union End Ball valve (allows maintenance of valve without emptying pot)

- Upsized High-Flow 1-1/2" Auto Air Valve

- MPN: 0531-338-01UV (pneumatic controls)

- MPN: 0532-338-01UV (electric controls)

- Similar to the standard Portable w/wheels, Pressure-Hold Blaster Package, but with the following changes:

- 6.5 cu. ft. BlastOne Contractor Package

- Same as above Axxiom Contractor Package with the following changes:

- TeraValve Metering Valve

- Standard 1-1/2" Auto Air Valve

- BlastOne Orange paint

- SKU: BMS65TERAA-US (pneumatic controls)

- SKU: BMS65TERAAE-US (electric controls)

- Same as above Axxiom Contractor Package with the following changes:

- 10 cu. ft. Blaster

- Designed for larger projects or industrial blast rooms. It is typically special ordered with customer chosen options, but the standard Axxiom version comes with:

- Stationary version on legs (no skid). (4-wheel portable version is optionally available)

- Pressure-release operation with ComboValve® & 1-1/2" MicroValve 3®

- Pneumatic G3 Trigger Compact BAABS deadman w/55' twinline control hose

- VBS II industrial muffler (no moisture separator)

- 1-1/2" Piping (Pot diameter is 24", same as 6.5 pot)

- 2-outlet ports (standard version comes with 1 outlet)

- MPN: 0731-128-10

- 20 cu. ft. Blaster

- Ideal for large, continuous blast room operations requiring reduced loading downtime. Similar to the 10 cf pot, it is typically special-ordered with custom features, but the standard Axxiom 20cf version comes with:

- Stationary version only (no optional wheels)

- Pressure-hold Thompson II valve w/urethane sleeve (suits steel grit applications)

- Pneumatic G3 Trigger Compact BAABS deadman w/55' twinline control hose

- VBS II industrial muffler (no moisture separator)

- 1-1/2" Piping (Pot diameter is 36")

- 2-outlet ports (standard version comes with 1 outlet)

- MPN: 0011-008-10

- Precision Control – Achieve consistent, high-quality surface finishes with advanced metering valves.

- Customizable Options – Configure your blasting system to match the needs of your application.

- Efficient Blowdown – VBS II™ technology ensures quieter, safer depressurization.

- Minimal Abrasive Loss – Available Pressure-hold systems reduce start-up and shutdown losses.

- Built for Durability – Designed to withstand the demands of industrial and contractor environments.

- Construction and Infrastructure Maintenance – Bridges, pipelines, and steel structures.

- Shipbuilding and Marine Restoration – Effective surface preparation for heavy-duty coatings.

- Industrial Blast Rooms – Customizable systems for high-volume blasting operations.

- Contractor Blasting Projects – Flexible systems adaptable for different job site conditions.

- Metal Fabrication and Restoration – Consistent and precise abrasive flow for finishing processes.

My Account

My Account