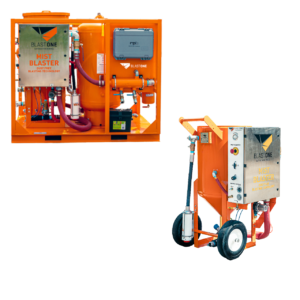

Schmidt AmphiBlast Mini 1.5 cuft Blast Pot

Sku: P-BMS15AMPHI

The Schmidt AmphiBlast™ Mini 1.5 cu. ft. is a highly portable, compact blasting system that provides both wet and dry blasting in one unit. As the smallest and lightest in the AmphiBlast family, it is designed for easy maneuvering into tight job sites and hard-to-access locations, offering maximum versatility and performance. Unlike traditional systems that mix water and abrasive inside the vessel (aka slurry blaster), the AmphiBlast system injects water into the blast stream after the metering valve. This design allows for fine-tuned control over the air, abrasive, and water flow, ensuring optimal blasting efficiency and minimal material waste. Operators can easily switch between wet and dry blast, blowoff, and Softwash™ modes without having to reset blasting parameters, using a centralized control panel. The system also features the Schmidt Tera Valve™ XL, ensuring precise and repeatable abrasive metering for coarse and fine media. Key Features & Benefits- Dual-function blasting – Switch between wet and dry blasting in seconds

- Ultra-portable design – Fits through a 24” doorway (even with onboard water tank)

- Minimal water consumption – Uses less than 1 pint / ½ liter per minute

- Electric water pump – Provides high-flow water for washdown or Softwash™ mode

- Precise control system – Adjust air, abrasive, and water flow for optimal performance

- Wide blasting pressure range (10–150 psi) – Ideal for both high-power and delicate applications

- Schmidt Tera Valve™ XL metering valve – Delivers accurate and repeatable abrasive flow

- Lower cross members for easy abrasive refilling – Ergonomic design simplifies operation

- Durable construction – Rugged locking lid and quieter blowdown system for enhanced usability

- Industrial surface preparation – Remove paint, rust, and coatings with wet or dry blasting

- Shipbuilding and marine restoration – Minimizes dust while providing effective blasting

- Bridge and infrastructure maintenance – Compact and easy to transport for onsite jobs

- Automotive and aerospace finishing – Provides precision control for detailed work

- General manufacturing and metal fabrication – Works with a variety of abrasive media

- Product Type: Portable Wet/Dry Abrasive Blasting System

- Abrasive Tank Capacity: 1.5 cu. ft.

- Piping: 1"

- Blasting Pressure Range: 10–150 psi

- Water Consumption: Less than 1 pint / ½ liter per minute Abrasive Metering Valve: Schmidt Tera Valve™ XL

- Control System: Available in either Pneumatic or 12v Electric. Each unit comes with the corresponding BAABS trigger deadman.

- Configurations:

- Blast Machine without tank

- Model with onboard 15 gallon water tank

- All models include blast pot lid and screen

- Portability: Fits through a 24” doorway, even with onboard tank

My Account

My Account