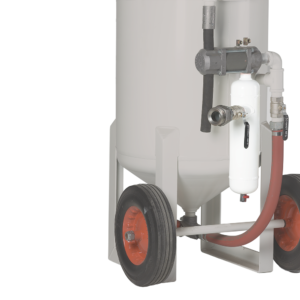

Schmidt® 3.5 cuft Blast Machine

Sku: P-BMS35

The Schmidt 3.5cf Blast Machine provides a versatile, portable, and durable solution for medium-sized abrasive blasting projects. This pot bridges the gap between the compact 1.5cf model and the full-size 6.5cf machines, offering more blasting capacity without the bulk and maneuverability limitations of larger units. It is ideal for applications where a 1.5cf pot is too small but a 6.5cf unit would be too cumbersome. Its compact footprint and built-in wheels make it easy to move across job sites, while its lighter weight compared to full-sized blast pots allows for easier setup and access in confined or restricted areas. The Schmidt 3.5cf Blast Pot maintains a full 150 PSI working pressure and includes a selection of abrasive metering valves and control system options to match the demands of your specific application. Key features of the Schmidt 3.5cf Blast Pot include:- Mid-sized 3.5 cubic foot capacity for jobs too large for a 1.5cf machine but too tight for a 6.5cf pot

- Durable, industrial-grade construction built for extended service life

- Ideal for facility maintenance, pipeline projects, shipyards, general contractors, and field service blasting

- Full working pressure rating of 150 PSI (10.3 bar) for reliable blasting performance

- Comes with 1-1/4″ piping for improved abrasive flow and system efficiency

- Choice of abrasive metering valves:

- Combo/MicroValve III® for fine media control

- Thompson II Valve® for rugged reliability and flexibility with multiple abrasives

- TeraValve XL® for low-maintenance, high-efficiency blasting

- Choice of control systems:

- Standard Pneumatic Controls for proven dependability

- 12V Electric Controls for cold-weather performance and long control lines (over 100 feet)

- Equipped with the innovative BAABS G3 Trigger-type deadman handle for ergonomic, responsive control

- Easy maintenance design with accurate abrasive metering and fast activation, ideal for stop-start projects

- Genuine Schmidt® product, manufactured by Axxiom Manufacturing

- BMS35CMA-US, Pneumatic, Combo/MicroValve

- BMS35CMAE-US, Electric, Combo/MicroValve

- BMS35TERAA-US, Pneumatic, TeraValve

- BMS35TERAAE-US, Electric, TeraValve

- BMS35TVA-US, Pneumatic, Thompson II Valve, TC

- BMS35TVAE-US, Electric, Thompson II Valve, TC

My Account

My Account