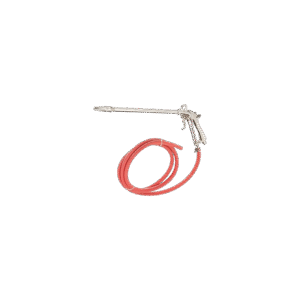

ENRX Induction Coating Removal Tool

Sku: HTMINAC

The ENRX Minac Coating Induction Tool is a game-changing solution for removing industrial coatings from metal substrates such as carbon steel and structural steel. Using advanced induction heating technology, the ENRX Minac tool dramatically reduces coating removal times—by as much as 90% compared to traditional methods—while providing a safer, more efficient work environment. FAQ's:- What is the minimum thickness of the substrate? Minimum thickness for use on carbon steel is 5mm (just over 3/16"). If there is a coating on the other side where disbonding is not wanted, then the minimum thickness is 8mm (5/16"). On 8mm steel, the back of the substrate during operation will be 175 to 200°F

- What is the maximum coating thickness it can remove? The maximum coating thickness during scan mode is about 10mm / 400 mils. During spot mode, the system can remove up to 40 mm / 1600 mils.

- How fast is it? When removing coatings that are 3-4mm (100-150 mils), the removal rate of production will normally be between 10-20 sq meters (100-200 square feet) per hour. Thicker coatings will take longer.

- Are there coatings it is not recommended for? The ENRX induction tool removes most coatings, with the exception of inorganic zinc (zinc-silicate). It is also not beneficial to use for thin coatings below 300 microns (12 mils).

- Does it eliminate the need to blast? In most cases, it will be necessary to do a light blasting after the induction process to achieve the surface condition required by the coating. There may be other technologies available for this as well.

- Does it work on substrates other than carbon steel? The ENRX Minac tool can be used on other electrically-conductive metals. However the system is designed for carbon steel and additional requirements exist if using on other metals. It is not recommended for use on aluminum substrates. Contact us for details.

- What prevents the system from overheating? The system is indirectly cooled by water. If suitable continuous flowing water less than 95°F is available at the site, and it is available at the correct flow and pressure, then a chiller may not be required. The water consumption is 11 liters / 3 gallons per minute. If the required water supply is not available, or if you are concerned about wasting water, a chiller is recommended to ensure proper water temperature for cooling, and since it is a self-contained system. The system cannot be used if the ambient temperature exceeds 42° C (107° F).

- What are the energy requirements? The system is electrically powered and uses 480v with a 40kW consumption during intermittent duty. The fuse / circuit breaker is recommended for 63 amps. This electric requirement does NOT include any electricity needed for a chiller.

My Account

My Account