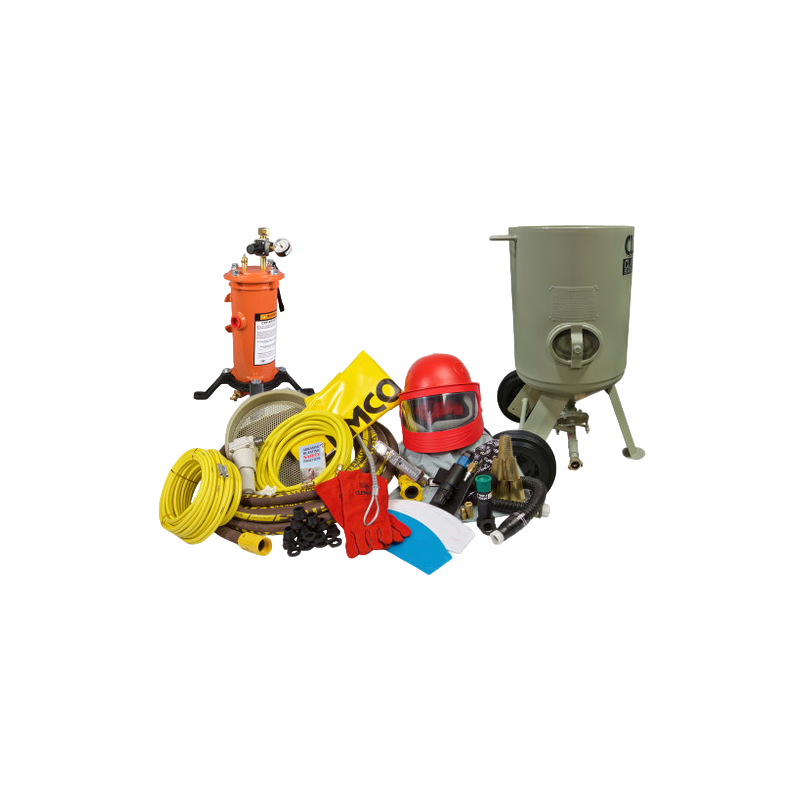

Clemco Blast Machines, 4/6 CF Classic and Contractor Pots

Sku: P-BMC6

Clemco Blast Machines are engineered to provide robust performance and long-lasting reliability in abrasive blasting operations. These machines come in various configurations, allowing you to choose the setup that best suits your specific needs. Whether you require a simple blast machine with a metering valve and remote controls or a complete package with all necessary accessories, Clemco has the option to match your requirements. Available Metering Valves for Clemco 4.0 & 6.0 CF pots

- FSV - Flat Sand Valve: This is an inexpensive valve that is available only in the Classic series. It is recommended for applications using slag or mineral abrasives (not metallic or plastic abrasives) and offers limited flow control.

- LPV: Similar to the FSV, the Lo-Pot Valve has the same features and limitations but in a lower profile design. Intended for use with the Low Profile design pot.

- MQV-Pro - Manual Quantum Valve: This upgrade from the legacy design MQV is now standard on all new MQV pot configurations. It is recommended for use with all media except lightweight types. With increased durability and better metering control, this new design offers greater media efficiency and lower maintenance costs in pressure-release applications.

- Auto Quantum Valve (AQV): Like the MQV, the AQV can handle all common abrasives. It is pneumatically operated and is used with either pressure-hold or pressure-release systems with Abrasive Cut-off Switch (ACS) remote abrasive controls.

- Grit Wizard: Clemco's latest metering valve boasts a substantially longer service life and is also pneumatically controlled for remote abrasive control for either pressure hold or pressure release applications.

Remote Controls:

- Classic Series. TLR-300 control system . These pressure-release pots use two control valves (inlet and outlet) as part of the deadman system.

- Available versions include:

- Outlet valve - Piston type. For general purpose use.

- Outlet valve - Diaphragm type. For use with fine-mesh or aggressive media.

- Note: All Classic series pots are supplied with pneumatic controls. If electric controls are required, they are available in the Contractor series.

- Contractor Series. Millennium Valve. This control valve combines the Inlet and Outlet functions into a single combination valve and is standard in the Contractor series.

- Contractor Series. Quantum Valve. Like the Millenium valve, this control valve is a combination valve, and is used in conjunction with the Abrasive Cut-off feature.

- Note: The optional Abrasive Cut-off (ACS) feature is available for both Classic and Contractor machines, and uses a special deadman handle (switch). Must be used with an AQV or Grit Wizard metering valve. This remote abrasive cut-off allows the operator to turn off the abrasive flow, providing convenient blow-off functionality.

- EAC 300 / EDC 300: Controlled electrically, this system is recommended for applications where the blast hose is over 100' and/or where temperatures will be cold, as the electric version eliminates the risk of control-line freeze-up. The EAC version is powered by a 120v AC supply, while the EDC version is powered by a 12v DC supply. (Both versions have 12v to the deadman handle to reduce shock risk to the operator.)

Blast Pot Packages:

- Full-package - High Pressure: Includes Blast Pot screen, HP hoods, breathing air filters, hoses, nozzles, and all necessary accessories, providing a ready-to-use solution for immediate blasting operations. They do not, however, include a Carbon Monoxide monitor (available separately).

- Full package - Low Pressure: Same as above except with LP hood, designed for use with Ambient Air Pump (available separately)

- Base machines: include the deadman control line and handle, along with the pot & metering valve.

- Lids & Screens: The screens are included on packages, but are optional on base machines. Steel lids are optional in all configurations.

Applications:

- Portable - includes wheels

- Stationary - for blast room applications

My Account

My Account