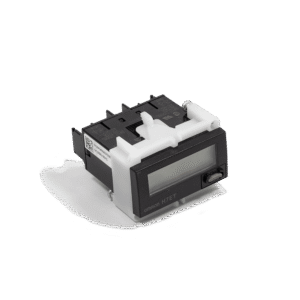

Blasting Time Clock for Blast Pot Nozzle

Sku: P-BATIM

Measure the individual blast operators to determine the actual amount of time the nozzles are running. This is accomplished with blast timers hooked into the deadman lines. These measurements are illuminating. You may have a team of three blasters who worked an 8 hour shift… but what percentage of that shift was actual blasting? How can you know for sure? On a lot of job sites, a substantial amount of time is spent on unproductive work which might involve shifting scaffold, prepping, filling pots with abrasive & lunch breaks. Without exception, every customer we’ve met that has put a Blast timer in place has gotten more productivity out of their teams. Not because they’re pushing people harder, or because they’re overdriving workers, but because management now becomes aware of all the little issues that chip away at the true nozzle time. Management begins to see the startling impact of having to move scaffolding – which may take hours. Realizing the effect this has on nozzle time, the idea of renting a Boom Lift, which originally seemed an unnecessary expense, now makes financial sense. It will increase productivity. Nozzle time will increase. Here’s another common scenario. Let’s pretend nozzle time is low. You question the blaster and discover his small blast pot only lasts 45 minutes to an hour before he must stop and refill. He then takes a smoke break, moves his hoses – and you’ve lost 20 minutes of blast time in the process. 20 minutes every hour for an 8 hour shift is 2 hours and 40 minutes of lost productivity. It makes more financial sense to upgrade to bulk pots and keep your team active than having them constantly refill small pots. What gets measured, gets managed. My Account

My Account