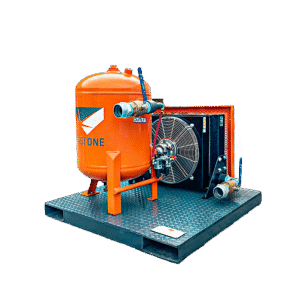

Schmidt® AirPrep™ Aftercooler Moisture Removal Systems

Sku: P-ACS

If you are serious about production blasting - that is, continual production blasting to earn profits each and every day - you'll need to invest in a serious moisture removal system. You should not underestimate the benefits of using cool, dry air for blasting. You can actually blast up to 15% faster! You never have to choke your blast machine, and your abrasive metering valve doesn't need constant adjustments - so you save money on abrasive. The ACS Aftercooler system uses an Aftercooler fan to cool the compressed air - the cool air then flows into a large coalescing tank where the cool air/moisture spins through stainless steel coalescing elements that drop the moisture out of the system. Pneumatic fan motor includes filter regulator lubricator and muffler. An electric fan motor is also available. There is negligible pressure loss through the AirPrep system thanks to the over-sized Radiator/Heat Exchanger. KEY FEATURES Designed for maximum performance to handle high humidity environments or offer a higher level of moisture removal for critical applications. If your blast operation or job site is in a region that experiences wide differences in the daily high and low temperatures, an air dryer is a must to handle the moisture generated in these environments. MAXIMUM PERFORMANCE SYSTEM Less than 3 psi pressure loss at 40% over stated capacity. Schmidt AirPrep Systems uses an oversized radiator for maximum flow and cooling. RUGGED, PORTABLE, AND TOUGH Schmidt AirPreps are skid mounted and have a heavy grating over the radiator to shield the unit from outside forces. They last forever. STAINLESS STEEL DEMISTER PAD Stainless steel coalescing demister pad for non-restrictive effective moisture removal - no restrictive elements. No replacement elements are required. My Account

My Account