Non-Woven-Abrasives

Our selection of non-woven abrasives provide an excellent solution for efficient and effective surface conditioning. Whether you need to clean, strip, or finish, our selection of Klingspor and 3M Scotch-Brite products deliver outstanding results with minimal effort. The non-woven structure ensures long-lasting performance and prevents clogging, making them suitable for various applications. If you’re looking for a reliable and high-performing abrasive solution, explore our range and find the perfect fit for your needs. For additional assistance or if you can’t find what you’re looking for, contact us or use our live chat feature for immediate support.

Showing all 3 results

-

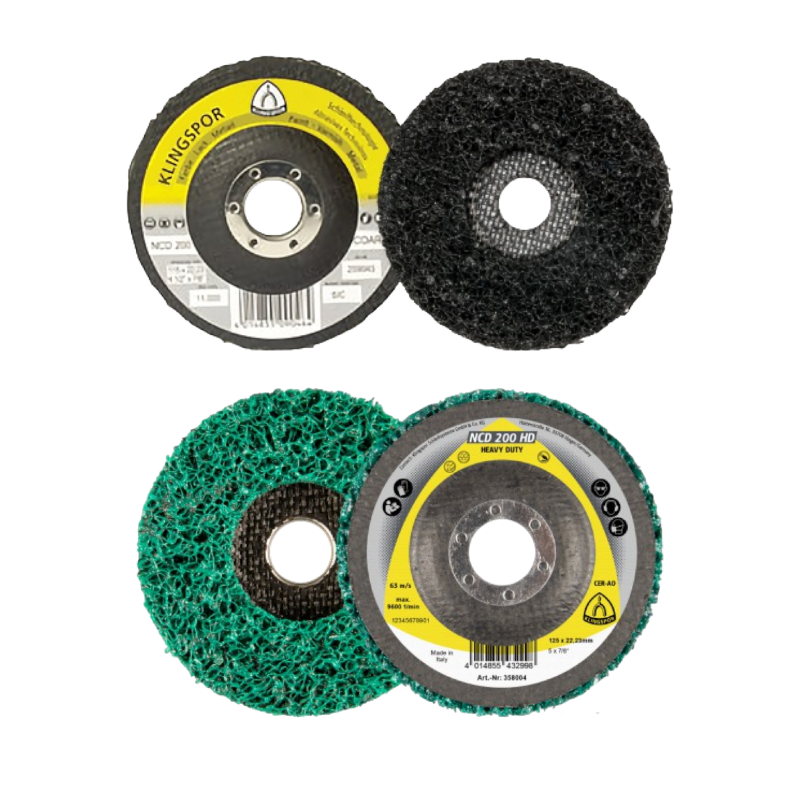

Klingspor is a major manufacturer of abrasive products for hand tools. These Powerwheels are closely akin to flap discs, but with a non-woven structure which virtually eliminates clogging. Also known as ‘clean and strip’ discs, they are excellent for cleaning surfaces, removing heat discoloration with the HD version being excellent at heavier duty applications requiring more aggression. Two versions as follows:

- NCD 200. Impregnated with silicon carbide for general purpose cleaning including removal of rust, mill scale, and paint.

- NCD 200HD. Impregnated with ceramic abrasive, this wheel will last the longest in demanding applications.

-

SPRSB50C

- Aggressively deburr and finish with this strong non-woven disc

- Consistent finishes are a cinch with the Roloc backing coupled with the conformable, non-woven disc

- Always runs cool and resistant to loading via open-web construction

- Roloc attachment system translates to fast, simple disc change-out for multi-step finishing processes

SPRSB50C- Aggressively deburr and finish with this strong non-woven disc

- Consistent finishes are a cinch with the Roloc backing coupled with the conformable, non-woven disc

- Always runs cool and resistant to loading via open-web construction

- Roloc attachment system translates to fast, simple disc change-out for multi-step finishing processes

-

SNR6114

- Avoid compromising the geometry of the workpiece and quickly remove paint, rust and coatings

- Small width allows for more complete cleaning - including tight corners

- Greater efficiency than wire brushes

- Extra coarse (XCS) grade silicon carbide provides aggressive cutting

- Load/heat resistance provides increased operation/results throughout product life

- Smear resistant

- Cut sharp and leave a bright finish with the silicon carbide mineral

SNR6114- Avoid compromising the geometry of the workpiece and quickly remove paint, rust and coatings

- Small width allows for more complete cleaning - including tight corners

- Greater efficiency than wire brushes

- Extra coarse (XCS) grade silicon carbide provides aggressive cutting

- Load/heat resistance provides increased operation/results throughout product life

- Smear resistant

- Cut sharp and leave a bright finish with the silicon carbide mineral

Discover the versatility and efficiency of non-woven abrasives with our premium selection at BlastOne. Our range includes Klingspor Power Wheels Surface Conditioning Discs and 3M Scotch-Brite products, designed to meet the highest standards in surface preparation. These abrasives offer superior performance in cleaning, deburring, and finishing, with a non-woven structure that prevents clogging and ensures consistent results. Ideal for removing rust, mill scale, paint, and coatings, these discs are perfect for all metals, stainless steel, and plastics. Choose from silicon carbide and ceramic impregnated options for both light and heavy-duty applications.

My Account

My Account

Cut-off wheels

Cut-off wheels Flap Discs

Flap Discs Grinding Discs

Grinding Discs Sanding Discs

Sanding Discs Wire Brushes & Wheels

Wire Brushes & Wheels Scaler Chisels & Needles

Scaler Chisels & Needles Quick Change Discs

Quick Change Discs Fibre Discs

Fibre Discs Non-Woven Pads & Backers

Non-Woven Pads & Backers Die Grinder Wheels

Die Grinder Wheels Flap Wheels & Backers

Flap Wheels & Backers Carbide Burrs

Carbide Burrs Other Abrasive Tooling

Other Abrasive Tooling