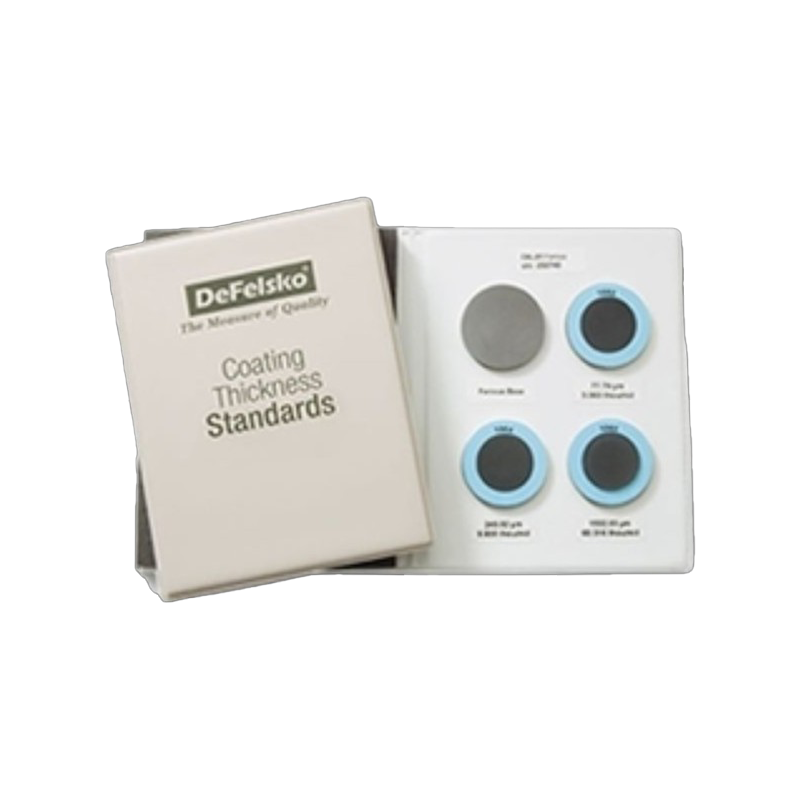

Verification Standards

DeFelsko’s verification standards are crucial for ensuring the precision and dependability of your testing instruments. Our selection includes certified coated metal plates, zero plates, step blocks, and plastic shims, suitable for a wide range of measurement needs. These standards are indispensable for verifying the accuracy of coating thickness gauges, hardness testers, and surface profile instruments.

Implement best practices in quality control and adhere to ISO 9000 standards with DeFelsko’s reliable and accurate verification solutions available at BlastOne.

Showing all 8 results

-

Thickness standards are used to verify the accuracy and operation of coating thickness gauges. As a component of ISO 9000 or in-house quality control procedures, they are a practical alternative to sending instruments to DeFelsko for calibration.

DeFelsko offers various solutions for this process and this group of products is their premium version comprised of 4 Certified polystyrene blocks, intended for probes that measure thick coatings (60 mils / 1500 microns and up)

Select the Standard set that most closely matches the measuring range of your probe. See selection chart under the Description tab.

-

Each DeFelsko instrument family is factory calibrated and is designed to be ready-to-use upon arrival. Best practice and specifications determine when instruments should have their calibrations rechecked. For the PosiTector UTG probes, DeFelsko offers five different variations of stainless steel Step Blocks that are factory certified for checking their calibration, as follows:

- B1. Standard range Imperial. Five steps (100, 200, 300, 400, and 500 mils).

- B1M. Standard range Metric. Five Steps (2.5, 5, 7.5, 10, and 12.5 mm).

- B2. High range Imperial. Eight steps (1", 1.5", 2", 2.5", 3", 3.5", 4", and 4.5").

- B2M. High range Metric. Eight steps (25, 37.5, 50, 62.5, 75, 87.5, 100, and 112.5 mm).

- P. (Use with PosiTector UTG P probe.) Imperial labeled at 40, 60, 80, and 100 mils. (Metric equivalent 1, 1.5, 2, and 2.5 mm)

-

Thickness Standards are used to verify the accuracy and operation of coating thickness gauges. As a component of ISO 9000 or in-house quality control procedures, they are a practical alternative to sending instruments to DeFelsko for calibration. These Plastic Shims (aka foils) are low-cost alternative to coated metal plates. They are available in Certified (individual shims or full sets) and in Un-Certified sets. Accuracy is somewhat less than metal plates and they are more sensitive to heat. They are intended for use over a Zero Plate, or over an uncoated substrate. A set of un-certified plastic shims is included with most electronic DeFelsko coating thickness gauges. Replacement sets and certified options are available here as follows:

- Un-Certified. These are checked for accuracy within tolerance shown below at DeFelsko, but are not traceable to any standard. They come as a set of 5 only, in the following approximate thicknesses:

- 25 microns / 1 mil (Orange), +- 20% accuracy

- 50 microns / 2 mils (Red), +- 10% accuracy

- 125 microns / 5 mils (Blue), +- 5% accuracy

- 250 microns / 10 mils (Brown), +- 5% accuracy

- 500 microns / 20 mils (Yellow), +- 5% accuracy

- Certified. Includes certificate of calibration traceable to PTB and all are accurate to within 2 microns / 0.08 mils. Available in the following thicknesses individually, or as a complete set of 8 shims:

- 25 microns / 1 mil (Orange)

- 50 microns / 2 mils (Red)

- 75 microns / 3 mils (Green)

- 125 microns / 5 mils (Blue)

- 250 microns / 10 mils (Brown)

- 500 microns / 20 mils (Yellow)

- 1000 microns / 40 mils (White)

- 1500 microns / 60 mils (Black)

- Un-Certified. These are checked for accuracy within tolerance shown below at DeFelsko, but are not traceable to any standard. They come as a set of 5 only, in the following approximate thicknesses:

-

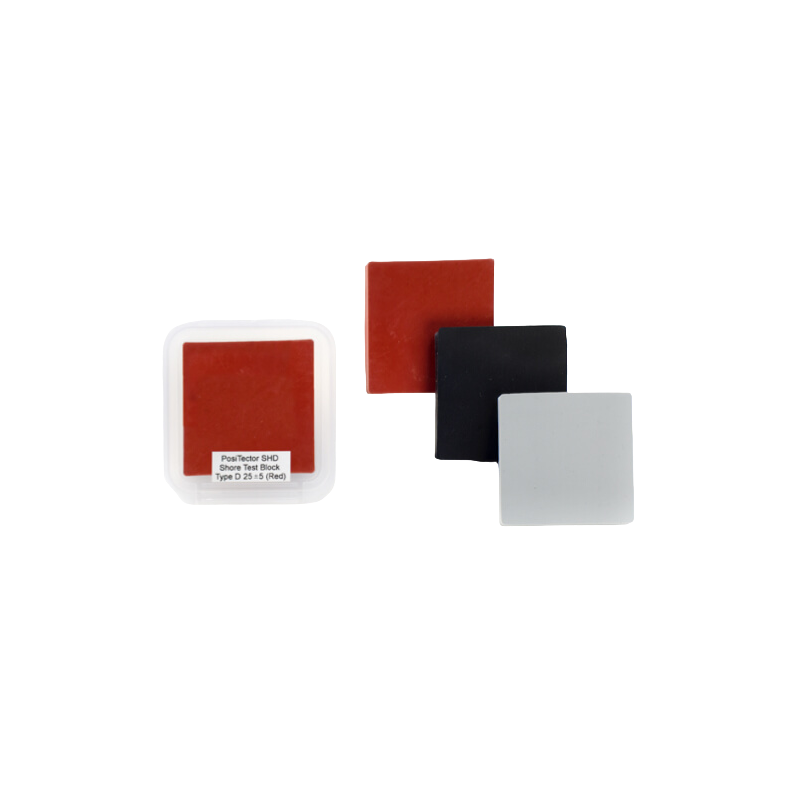

PosiTector SHD Test Blocks - DeFelsko accessories for checking the operation of the SHD Durometer Probes. Available in 3 variations each for Shore A and Shore D hardness measurement ranges.

-

Surface Profile Standards and Shim Sets are used for checking and adjusting calibration on PosiTector SPG, PosiTector RTR (and other depth micrometer probe) instruments. Product details as follows:

- For the PosiTector SPG:

- Certified Standards. Typically used in calibration labs, these are available for any user who desires this level of verification. Includes serialized and traceable height standards mounted to a metal plate. Labeled in both metric and imperial units.

- Certified Shim Set. Premium option for everyday use with any depth micrometer using a fine-pointed probe (as well as the PosiTector SPG). Includes 3 shims at 50/125/500 microns (2, 5, 20 mils).

- Zero Glass Plate / Metal Shim (Non-Certified). For training and quick checks for accuracy, each new SPG unit comes with this verification set, with replacement / additional units also available for purchase here.

- For the PosiTector RTR: (both models unless otherwise noted)

- Certified Shim Set. Premium option to check Peak Height measurements for accuracy verification on the RTR series (as well as other spring micrometer replica tape readers).

- Non-Certified Shim Set (aka Precision Plastic Shim Set). Lower cost version of the above, ideal for everyday accuracy verification.

- Single Check Shim. This non-certified shim comes standard with each new RTR and is available as a replacement if desired, although it is more economical to purchase the above full set.

- Check Tape. This reusable tape is used to verify Peak Density, and is used on the RTR 3D model only.

- For the PosiTector SPG:

-

INEBSPG

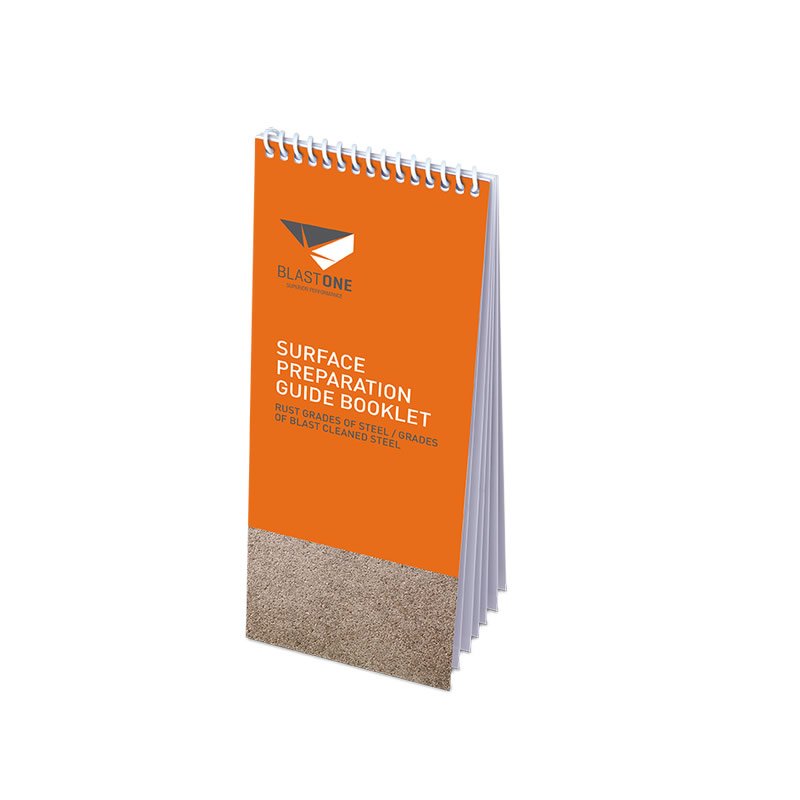

- Visual representation of rust and coating preparation grades on steel substrates

- Similar to SSPC-VIS 1 Visual Standards and Reference Photographs

- Handy flip-top, wire bound, reference book

- Provides a visual comparison with SSPC standards. Full color photographs. Wipe-clean gloss pages. Flip top wire binding. Supplied in a protective pouch.

- Not a certified visual standard - use as a guide

INEBSPG- Visual representation of rust and coating preparation grades on steel substrates

- Similar to SSPC-VIS 1 Visual Standards and Reference Photographs

- Handy flip-top, wire bound, reference book

- Provides a visual comparison with SSPC standards. Full color photographs. Wipe-clean gloss pages. Flip top wire binding. Supplied in a protective pouch.

- Not a certified visual standard - use as a guide

Ensure the accuracy and reliability of your testing instruments with DeFelsko’s comprehensive range of verification standards. Our certified and non-certified standards, including coated metal plates, polystyrene blocks, zero plates, step blocks, plastic shims, and more, are essential for maintaining compliance with ISO 9000 and in-house quality control procedures. Designed for various applications, these standards help verify the operation and calibration of coating thickness gauges, hardness testers, and surface profile instruments. Trust DeFelsko and BlastOne for all your verification needs.

My Account

My Account

Adhesion Testing

Adhesion Testing Air Leak Testing

Air Leak Testing Calibration

Calibration Coating Thickness

Coating Thickness Concrete Moisture

Concrete Moisture Environmental Conditions

Environmental Conditions Gloss Measurements

Gloss Measurements Hardness Testing

Hardness Testing Inspection Accessories

Inspection Accessories Inspection Kits

Inspection Kits Oven Profile

Oven Profile Pinhole & Holiday Testing

Pinhole & Holiday Testing Surface Contamination

Surface Contamination Surface Profile

Surface Profile Wall Thickness

Wall Thickness