Blasting, UHP & Site Equipment

Showing 91–105 of 617 results

-

OEM Clemco blast machine lids and screens are useful accessories for many applications. Lids keep the pots from collecting debris - especially when used outdoors. Screens are highly recommended for preventing foreign matter out of the pot when refilling abrasive. They are standard with most new Clemco blast machine packages, but lids are optional. Both are available here in sizes to match any size blast pot from 0.5CF (10") to 20 CF (36").

-

The Clemco Beacon LED Blast Light is a high-performance, 860-lumen LED light designed to enhance visibility during abrasive blasting. Available in both 12-volt DC and 120-volt AC models with options for 50 ft or 100 ft power cords, this blast light improves operator productivity in poorly-lit environments.

- Available in 12-volt DC and 120-volt AC models

- Includes 50 ft or 100 ft of power cord

- 860-lumen, 6000k daylight-color temperature

- Mounts to the blast hose or nozzle holder

- Quick-change Pyrex® lens for easy maintenance

- Compact, lightweight, and rugged for harsh environments

-

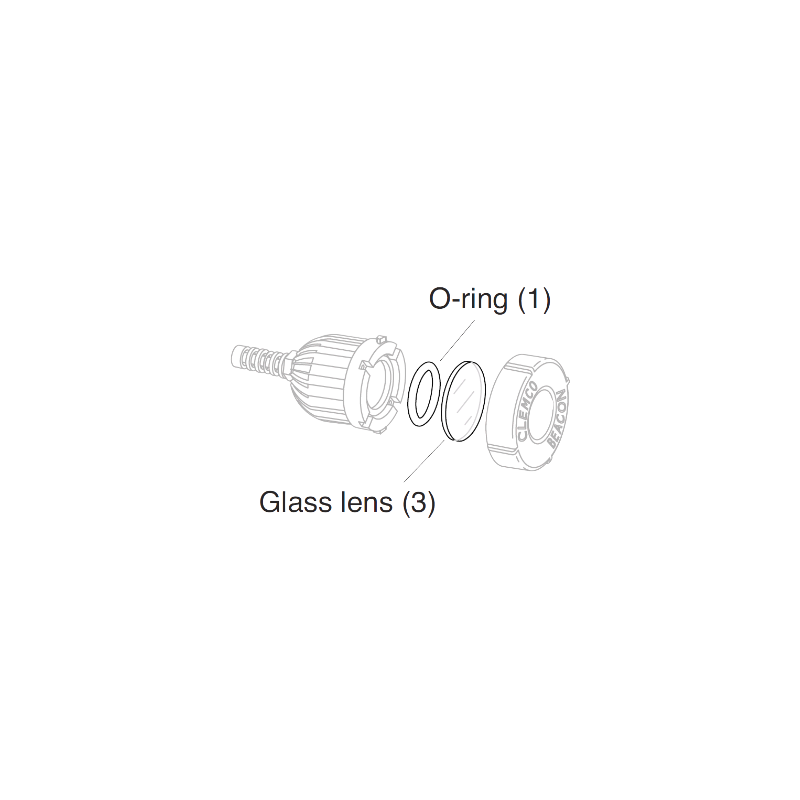

BABL28163The Clemco Beacon Outer Lens Service Kit (MPN: 28163) - (SKU: BABL28163) is designed to maintain the performance of your Clemco Beacon LED Blast Light. This kit includes three durable replacement glass lenses and a replacement O-ring to ensure dust-tight sealing and optimal illumination in abrasive blasting environments. Key Features:

- Complete Kit: Includes (3) high-quality glass lenses and (1) O-ring for quick and easy lens replacement.

- Easy Maintenance: Designed for simple field replacement to minimize downtime.

- Enhanced Durability: High-quality glass lenses withstand abrasive environments.

- Restored Performance: Keeps your Clemco Beacon Blast Light functioning at peak efficiency.

- Cost-Effective Solution: Replace worn-out components without purchasing a new light assembly.

BABL28163The Clemco Beacon Outer Lens Service Kit (MPN: 28163) - (SKU: BABL28163) is designed to maintain the performance of your Clemco Beacon LED Blast Light. This kit includes three durable replacement glass lenses and a replacement O-ring to ensure dust-tight sealing and optimal illumination in abrasive blasting environments. Key Features:- Complete Kit: Includes (3) high-quality glass lenses and (1) O-ring for quick and easy lens replacement.

- Easy Maintenance: Designed for simple field replacement to minimize downtime.

- Enhanced Durability: High-quality glass lenses withstand abrasive environments.

- Restored Performance: Keeps your Clemco Beacon Blast Light functioning at peak efficiency.

- Cost-Effective Solution: Replace worn-out components without purchasing a new light assembly.

-

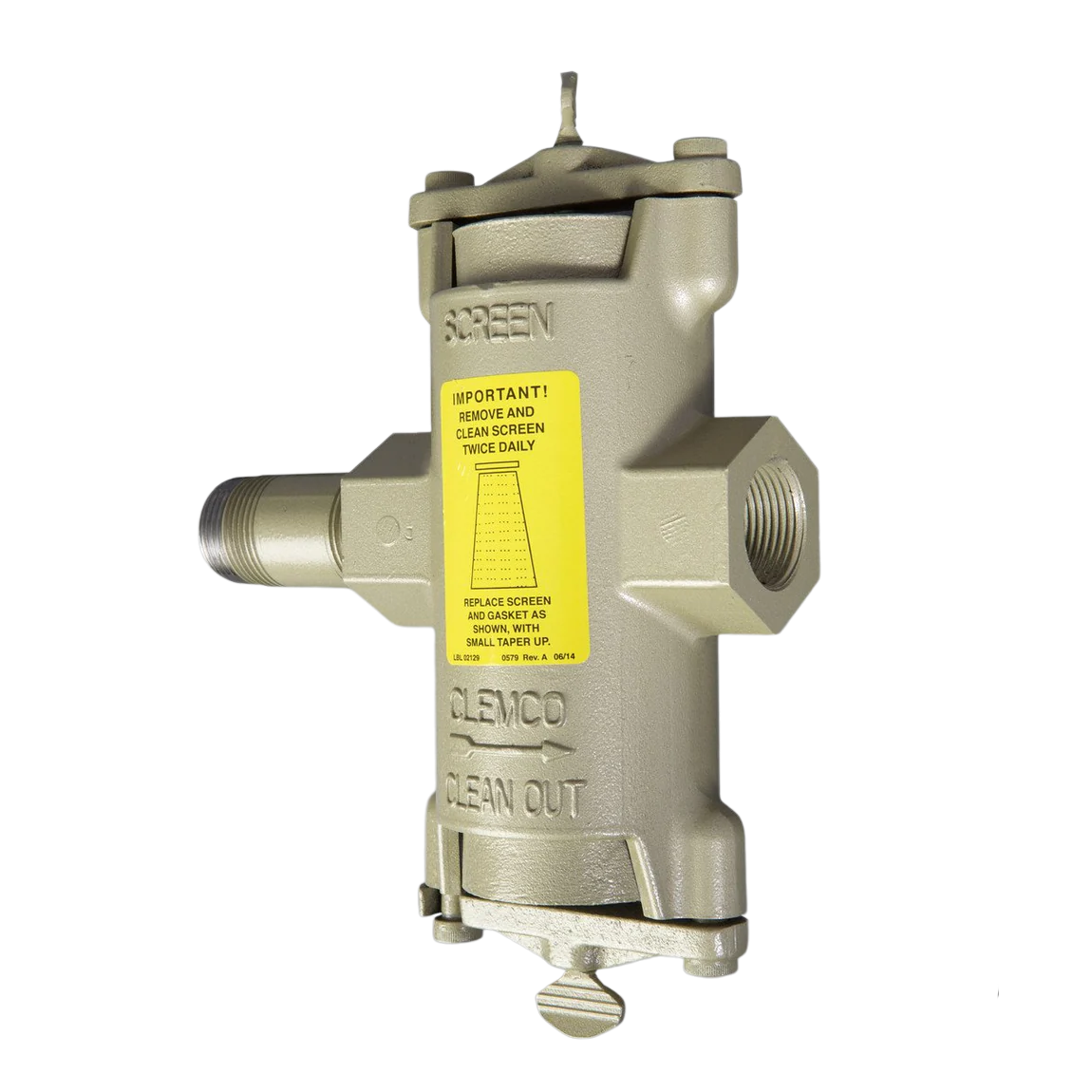

The Clemco 1-Inch Abrasive Trap ensures reliable abrasive containment and system protection. Designed for compatibility with TRL-100 and TLR-300 Remote Systems, this complete abrasive trap features a 1-inch National Pipe Thread (NPT) connection, making it essential for maintaining blasting efficiency and equipment longevity. Key Features:

- 1-inch NPT connection for secure integration

- Compatible with TRL-100 and TLR-300 Remote Systems

- Complete assembly for easy installation

- Durable construction for long-lasting performance

-

BABL27758The Clemco Beacon Light Replacement 120V to 12V Driver (SKU: BABL27758) is a reliable OEM replacement part designed to convert 120V AC power to 12V DC for Clemco Beacon LED Blast Lights. This field-serviceable driver ensures optimal performance, longevity, and minimal downtime during abrasive blasting operations.

- Voltage Conversion: Converts 120V AC to 12V DC for optimal LED light functionality.

- Field Serviceable: Easy to replace, minimizing downtime during operations.

- Durable Design: Built to withstand harsh abrasive blasting environments.

- Cost-Effective: Replace the driver without purchasing a new light assembly.

- Compatibility: Designed for Clemco Beacon LED Blast Lights (50 ft and 100 ft models).

- MPN: 27758

BABL27758The Clemco Beacon Light Replacement 120V to 12V Driver (SKU: BABL27758) is a reliable OEM replacement part designed to convert 120V AC power to 12V DC for Clemco Beacon LED Blast Lights. This field-serviceable driver ensures optimal performance, longevity, and minimal downtime during abrasive blasting operations.- Voltage Conversion: Converts 120V AC to 12V DC for optimal LED light functionality.

- Field Serviceable: Easy to replace, minimizing downtime during operations.

- Durable Design: Built to withstand harsh abrasive blasting environments.

- Cost-Effective: Replace the driver without purchasing a new light assembly.

- Compatibility: Designed for Clemco Beacon LED Blast Lights (50 ft and 100 ft models).

- MPN: 27758

-

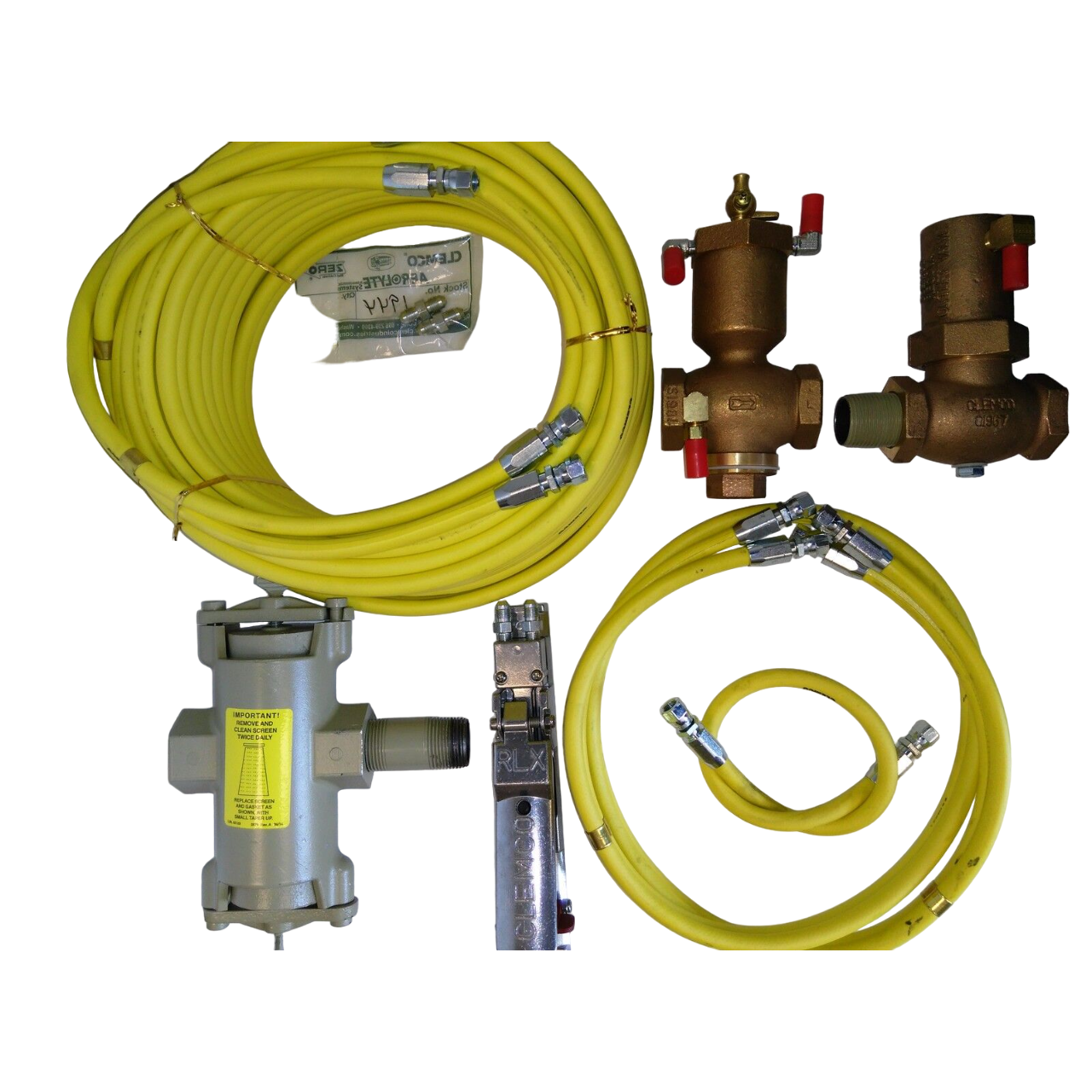

- Clemco TLR-50 / TLR-300 Deadman Controls are the primary safety system for Clemco Classic Series pneumatic blast machines

- Ensure automatic deactivation if the operator loses control of the blast nozzle.

- The system can be configured in various ways, depending on the blast machine, what media is being used, and what features are needed.

- The Clemco control systems in this section are complete systems. Complete systems are necessary only when completely refurbishing a pot.

- Individual valves and other repair components are available separately.

-

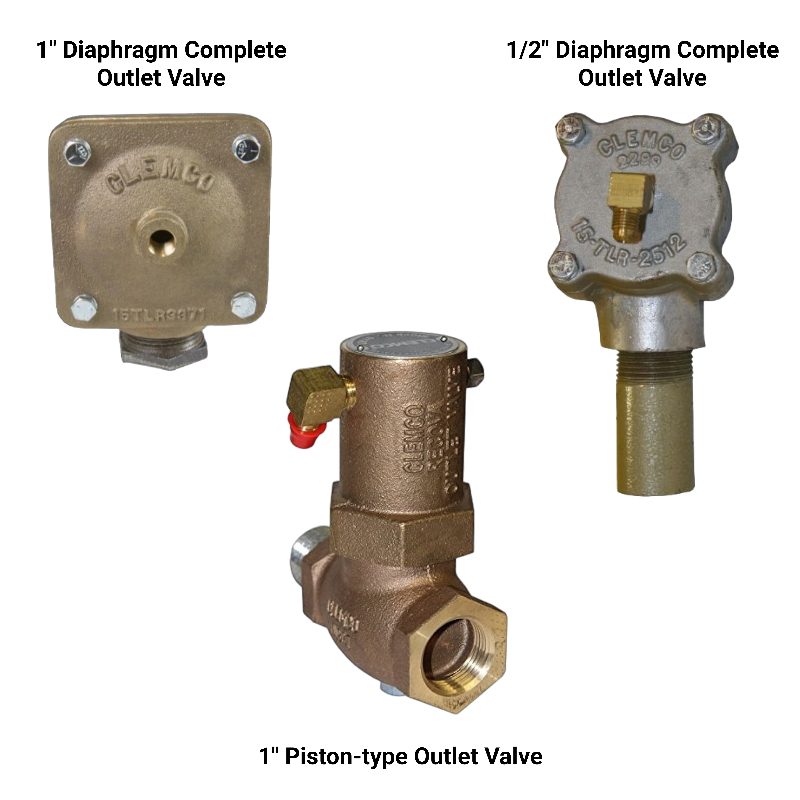

Genuine OEM Clemco Outlet Valves ensure reliable performance and longevity for your blasting operations. Available in piston and diaphragm styles, these outlet valves are designed to accommodate a variety of remote control systems and abrasive types, offering superior durability and versatility.

Key Options:

- 1-Inch Piston Outlet Valve: Ideal for standard applications with remote controls.

- 1/2-Inch Diaphragm Outlet Valve: Suited for TRL-50 pneumatic remote controls.

- 1-Inch Diaphragm Outlet Valve: Perfect for TRL-100/300 controls and fine or aggressive abrasives.

-

BAP03699Maintenance of the pop-up assembly is essential for preventing differential pressure issues in blast machines. BlastOne offers OEM Clemco repair parts including this pop-up valve & shaft assembly (with external sleeve). This 4" size dome is used in all current sizes of Clemco pots between 1.5 and 20 c.f. It is commonly used with either the Clemco 02325 rubber seating ring (standard applications) or the Clemco 02380 neoprene seating ring (use in hot climates). MPN: 03699BAP03699Maintenance of the pop-up assembly is essential for preventing differential pressure issues in blast machines. BlastOne offers OEM Clemco repair parts including this pop-up valve & shaft assembly (with external sleeve). This 4" size dome is used in all current sizes of Clemco pots between 1.5 and 20 c.f. It is commonly used with either the Clemco 02325 rubber seating ring (standard applications) or the Clemco 02380 neoprene seating ring (use in hot climates). MPN: 03699

-

AC22XJ80

The Wizard is a robust and powerful ventilation fan, that is rebuildable when required. The Air Motor Repair Kit is a convenient pack which includes the necessary bearings, seals, and more to rebuild the AC22UX50 5.25hp air motor used in the pneumatic Wizard fan.

AC22XJ80The Wizard is a robust and powerful ventilation fan, that is rebuildable when required. The Air Motor Repair Kit is a convenient pack which includes the necessary bearings, seals, and more to rebuild the AC22UX50 5.25hp air motor used in the pneumatic Wizard fan.

-

AFAL05537Maintain safe operation of pneumatic deadman systems during cold temperatures with this antifreeze injector kit. Designed for all Clemco pneumatic control systems, this injector assembly can prevent the deadman from dangerous icing. MPN: 05537AFAL05537Maintain safe operation of pneumatic deadman systems during cold temperatures with this antifreeze injector kit. Designed for all Clemco pneumatic control systems, this injector assembly can prevent the deadman from dangerous icing. MPN: 05537

-

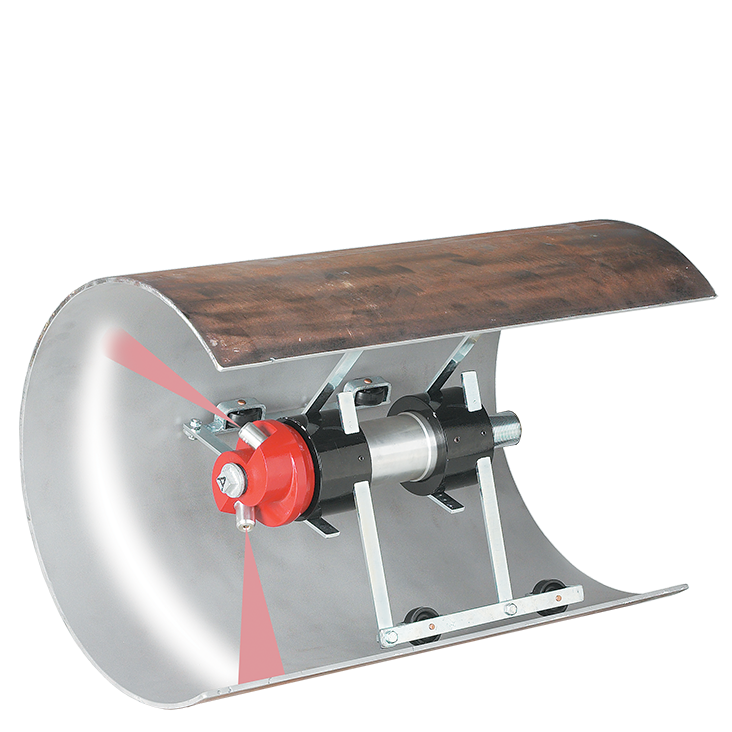

IPC1000The RotorBlast is the fastest way to blast the internals of pipes. This IPC1000 version is designed for pipes from 10" to 35" ID. Fast and effective blasting is ensured by the twin-nozzle spinning blast head. Additional details of this Internal Pipe Blaster are as follows:

- 360 degree blasting covers the entire ID of the pipe

- Speed is manually controlled. Optional electric winch is also available, helping to save labor and aid consistency in results.

- This IPC1000 pipe blasting tool works in pipes 10" to 35" ID

- Nozzles sold separately - details below:

- 2 nozzles are required for this unit.

- Use BNAT nozzles for pipes from 8" to 11" ID.

- Use BNASB nozzles for pipes from 12" to 36" ID.

- Centering carriage sold separately - details below:

- IPC1200 Centering Carriage is required and is adjustable to work in pipes from 8 to 36" in diameter.

- Note: ID blasting equipment requires significant maintenance. A Rotorblast Repair Parts Kit is available for convenience, or individual parts may be purchased under the Parts Tab. An operators manual is shown under the documents tab or you can contact us for further information.

IPC1000The RotorBlast is the fastest way to blast the internals of pipes. This IPC1000 version is designed for pipes from 10" to 35" ID. Fast and effective blasting is ensured by the twin-nozzle spinning blast head. Additional details of this Internal Pipe Blaster are as follows:- 360 degree blasting covers the entire ID of the pipe

- Speed is manually controlled. Optional electric winch is also available, helping to save labor and aid consistency in results.

- This IPC1000 pipe blasting tool works in pipes 10" to 35" ID

- Nozzles sold separately - details below:

- 2 nozzles are required for this unit.

- Use BNAT nozzles for pipes from 8" to 11" ID.

- Use BNASB nozzles for pipes from 12" to 36" ID.

- Centering carriage sold separately - details below:

- IPC1200 Centering Carriage is required and is adjustable to work in pipes from 8 to 36" in diameter.

- Note: ID blasting equipment requires significant maintenance. A Rotorblast Repair Parts Kit is available for convenience, or individual parts may be purchased under the Parts Tab. An operators manual is shown under the documents tab or you can contact us for further information.

-

BNATC360COffers Quick and Easy Setup for blast cleaning on internals of small pipes

- Blasts in a 360 degree pattern

- Can be used in pipes from 2.5 to 5 inch ID

- Machined aluminum jacket with tungsten carbide liner

- Replaceable tungsten carbide deflector tip

- Coarse, 2" Contractor Thread

- Screws directly into nozzle holder

- NOTE - requires Nylon nozzle holder with contractor threads

BNATC360COffers Quick and Easy Setup for blast cleaning on internals of small pipes- Blasts in a 360 degree pattern

- Can be used in pipes from 2.5 to 5 inch ID

- Machined aluminum jacket with tungsten carbide liner

- Replaceable tungsten carbide deflector tip

- Coarse, 2" Contractor Thread

- Screws directly into nozzle holder

- NOTE - requires Nylon nozzle holder with contractor threads

-

Clemco offers a wide range of equipment that provides high-efficiency 360-degree cleaning for pipe interiors. Suitable for industrial applications, these tools are capable of providing precise and effective surface preparation. The two Hollo-Blast unit versions function essentially as nozzles, and work by utilizing a deflection tip at the end of the orifice. The tip deflects the abrasive into a 360° pattern. They are designed for pipes ranging from only ¾" - 2" ID (Junior Series) to 2" to 12" ID (standard Hollo-Blast Series). Larger ID pipe can also be done, but with a different series of equipment. Optional centering carriages are also available, adding efficiency and consistency to the blast. Internal Pipe blasting is a specialized process involving high wear on certain components. BlastOne's technical staff is available to assist with your questions.

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment