Blasting, UHP & Site Equipment

Showing 61–75 of 629 results

-

GRACO® SPECIAL PURCHASE - BLAST HOSE FINAL CLEARANCE! These hoses, originally produced for the Graco EcoQuip series, are top quality, new condition and suitable for any blasting equipment - wet or dry. At half the price of our standard bare hose, these 2-ply, 1" ID whip hoses on final clearance pricing INCLUDE first quality fittings, control line, and in some cases, deadman switches.

- ‘Bulk’ Blast Hose - everyday blasting and whip hose, without fittings or accessories - SOLD OUT

- ‘Pneumatic Control’ (aka "Replacement) Hose - Blast hose fitted with coupling on one end, nozzle holder on the other, Schmidt G2 Pneumatic Deadman Control Handle, and twinline control hose

- ‘Pneumatic Extension’ Hose - Blast hose fitted with couplings on both ends and twinline control hose

- ‘Electric Control’ (aka ‘Replacement’) Hose - Blast hose fitted with coupling on one end, nozzle holder on the other, Schmidt G2 Electric Deadman Control Handle, and electric control cable

- ‘Electric Extension’ Hose - Blast hose fitted with couplings on both ends and electric control cable.

- Note - Fitted hoses may come with either nylon or brass fittings - see the individual images.

This special close-out purchase is limited to stock on hand and will be available on a first-come, first-served basis until they are gone. NOTE: Must call 1-800-999-1881 or Chat (see lower right corner) to confirm availablilty before placing your order!!

-

Clemco Industries is the world's largest manufacturer of air-powered blasting equipment. It is over 80 years old, being founded in 1941. Clemco offers two series of blast machines - the Classic and the Contractor Pots. While both are designed for industrial applications, there are a few primary differences which are shown in the table below:Other features, such as pressure-hold or pressure-release deadmans, accessory packages, etc. are available on either series. The economy Classic blast pot with the FSV (flat sand valve) is the best-selling Clemco blast machine. The Contractor series offers more time saving and protection features. This Clemco Blast Machine group includes the 4 and 6 cubic foot versions.

Classic Series Contractor Series Controls Pneumatic standard. Electric only by special quote. Pneumatic or Electric Control Valves Separate Inlet / Outlet valves. Millennium or Quantum (combination inlet/outlet) Design Highlights Portable w/2 wheels. Improved portability (4 wheels) and protection (built-in tube steel handles around valves). Built-in storage for manuals. Improved access to hose fittings. Nomenclature 2452 Std. 6.0cf 2443 Lo 6.0cf (both 24" dia) 2020 4.0cf (20" diameter) 2024 6.0cf (24" diameter) -

Snakebite. The world's quietest blast nozzle!

BlastOne's SnakeBite XQ Silenced Blast Nozzle is engineered to be the world's quietest blast nozzle, prioritizing both operator safety and comfort. This innovative nozzle, exclusively designed by BlastOne, significantly reduces noise levels while enhancing performance, making it an essential tool for professionals in the blasting industry.- Up to 16dBA noise reduction

- Up to 45% less thrust compared to standard blast nozzles, greatly reducing operator fatigue and improving safety at heights

- Improved nozzle geometry

- New technology quick-connect nozzle silencer

- Durable and lightweight Silicon Nitride nozzle and silencer liner

- Slim ergonomic nozzle jacket

- Available with Contractor threads only, which are recommended. If Fine thread nozzle holders are a site requirement, use a Nozzle Thread Adaptor.

- 2 versions available

- Standard Pressure Nozzle effective between 90-110 psi

- Low Pressure (LPS) Nozzle effective between 70-90 psi

- FREE TRIAL AVAILABLE

- Click for Buying Guide

-

All the power. Half the size!

BlastOne's SnakeBite Flex Silenced Blast Nozzle is the ultimate solution for blasting in tight spaces without compromising power or performance. Exclusively engineered by BlastOne, this compact nozzle delivers all the benefits of the SnakeBite family, including noise reduction and reduced operator fatigue, while being small enough to navigate hard-to-reach areas with ease.- Up to 16dBA noise reduction

- Up to 45% less fatigue compared to standard blast nozzles

- Improved nozzle geometry

- New technology quick-connect nozzle silencer

- Durable and lightweight Silicon Nitride nozzle and silencer liner

- Slimline ergonomic nozzle jacket

- Standard contractor nozzle inlet thread

- 2 versions available

- Standard Pressure Nozzle effective between 90-110 psi

- Low Pressure (LPS) Nozzle effective between 70-90 psi

- FREE TRIAL AVAILABLE

Act quick! Limited supply.

-

BNSBXQ10-1BlastOne's SnakeBite Strike #10 Silenced Blast Nozzle is engineered to deliver the highest productivity in hand-held blasting, making it an essential tool for professionals tackling extensive surface preparation tasks. This innovative nozzle, exclusively developed by BlastOne, offers unparalleled performance with significantly reduced operator fatigue.

- WATCH VIDEO IN THE IMAGE SLIDER

- Highest productivity hand held blast nozzle available

- Over double the productivity of a #8 high performance blast nozzle with less operator fatigue

- Half the thrust of other #10 blast nozzles available - Feels like you're blasting with a #7 nozzle

- Up to 16dBA noise reduction - That's 75% quieter!

- Ideal for blasting acres of steel such as storage tanks, bridges and ship hulls

- Standard contractor nozzle inlet thread

- Delivers faster cleaning rates and increased profit by reducing project duration

- Requires 750cfm compressor

- FREE TRIAL AVAILABLE!

BNSBXQ10-1BlastOne's SnakeBite Strike #10 Silenced Blast Nozzle is engineered to deliver the highest productivity in hand-held blasting, making it an essential tool for professionals tackling extensive surface preparation tasks. This innovative nozzle, exclusively developed by BlastOne, offers unparalleled performance with significantly reduced operator fatigue.- WATCH VIDEO IN THE IMAGE SLIDER

- Highest productivity hand held blast nozzle available

- Over double the productivity of a #8 high performance blast nozzle with less operator fatigue

- Half the thrust of other #10 blast nozzles available - Feels like you're blasting with a #7 nozzle

- Up to 16dBA noise reduction - That's 75% quieter!

- Ideal for blasting acres of steel such as storage tanks, bridges and ship hulls

- Standard contractor nozzle inlet thread

- Delivers faster cleaning rates and increased profit by reducing project duration

- Requires 750cfm compressor

- FREE TRIAL AVAILABLE!

-

Designed with an extra-long venturi and concentrated blast pattern, the Hyper (aka XL or Saber) nozzle increases performance substantially. Additional details as follows: Click for Buying Guide

- Performance characteristics:

- Up to 30% faster coating removal and/or

- Allows greater stand-off distance (reduces need to bend over when blasting tank floors, allows greater reach, etc.)

- Thread types & Orifice Size options:

- Contractor 2" (50mm)

- Fine 1-¼" (32mm)

- Orifice size options: 5, 6, 7, 8, & 10

- Liner Options:

- SiALON silicon nitride, provides longer life and lighter weight than tungsten carbide.

- TC tungsten carbide, lower initial investment

- Jacket:

- Most are all aluminum with non-slip knurled finish, some have a poly jacket

- Design:

- 1-¼" throat entry, extended venturi, 12 inches long

- Performance characteristics:

-

The Ultra-Tuff Extended Life Silicon Nitride Blast Nozzle (SKU: P-BNULTRA) is built for industrial blasting, lasting twice as long as standard nozzles while being lightweight and highly efficient. Its Venturi design boosts productivity by up to 40%, and the durable silicon nitride liner with a shock-absorbent polyurethane jacket ensures exceptional performance. Click for Buying Guide Features:

- Venturi bore: 40% faster production than straight bore nozzles.

- Thread options: Contractor (2” / 50mm) and Fine (1-¼” / 32mm).

- Orifice sizes: #3–#8 to suit various tasks.

- Throat Entry:

- 1″ throat entry on #3 and #4 Contractor thread AND all Fine thread options

- 1-¼” throat entry on #5, 6, 7, and 8 Contractor threads

- Silicon nitride liner: Longer life, lighter than tungsten carbide.

- Polyurethane jacket: Protects against shocks and jams in metal holders.

- Lightweight: Reduces operator fatigue, half the weight of tungsten carbide.

-

BlastOne's SnakeBite XP Blast Nozzle is the high-performance alternative to the popular SnakeBite XQ silenced configuration. Designed for professionals seeking maximum blasting efficiency, the XP model utilizes a simple bump cap instead of a silencer, resulting in unmatched speed and performance without the noise and thrust reduction features of its counterpart.

-

Performance:

- The advanced modeling used when designing this Snakebite XP hyper nozzle has taken blasting performance to a whole new level. The refined internal geometry coupled with the non-silencing bump cap produces very fast cleaning speed indeed.

-

Liner:

- The new internal geometry when combined with the silicon nitride composition extends usable life greatly.

-

Jacket:

- Anodized aluminum with an ergonomic shape makes for a very comfortable grip.

-

Sizes:

- Available in the following orifice sizes: 6, 7, 8, & 10

- Overall length varies from 10" to 13", depending on orifice size.

-

Thread type:

- Available in standard 2" Contractor thread only. (See You May Also Like nozzle thread adapters below if you want to use with fine thread nozzle holders.)

Note: Inquire for details about our free trial offer.

-

Performance:

-

BlastOne's SnakeBite Blast Nozzle Silencers are revolutionary replacements designed exclusively for the SnakeBite family of nozzles. These silencers enhance workplace safety and operator comfort, making them ideal for blasting in noise-sensitive environments while maintaining exceptional performance.

- Replacement silencers for the SnakeBite family of blast nozzles

- Up to 45% less operator fatigue

- Up to 16dB noise reduction

- 2 versions available

- Standard Pressure Silencer effective between 90-110 psi

- Low Pressure Silencer (LPS) effective between 70-90 psi

-

Designed with a 60% larger blast pattern, the Raptor (aka Bazooka) nozzle makes short work of your large commercial blast / sweep blast / brush blast projects. Additional details as follows: Click for Buying Guide

- Thread types:

- Contractor (2") aluminum threads

- Fine (1-¼") brass threads

- Liner Options:

- Silicon nitride, offers lighter weight and generally longer life than tungsten carbide.

- Tungsten carbide

- Jacket:

- Urethane, for improved resistance to damage

- Design:

- 1-¼" throat entry, extended venturi

Note: As the Bazooka nozzles have metal threads, they work best with nylon nozzle holders and HFG32P (NW-32) nozzle washers.

- Thread types:

-

INBNATMaintain optimal blasting efficiency with our Abrasive Blasting Nozzle Wear Gauge Set, designed for quick and accurate assessment of nozzle wear in sizes #6, #7, #8, and #10. Featuring an extended design, this tool allows for measurements without removing the nozzle from its holder and eliminates the need for additional instruments like pencils. Regular use helps detect wear as small as 1/32", ensuring timely nozzle replacements to maintain peak performance.

- Measures nozzle sizes: #6, #7, #8, and #10

- Detects wear starting at 1/32"

- Extended length enables in-place measurements without nozzle removal. Simply drop in the applicable gauge into the end of the nozzle and if it goes through, it's time to replace!

- No additional tools required for operation

- Enhances blasting efficiency by identifying worn nozzles promptly

- Durable construction for long-term use

INBNATMaintain optimal blasting efficiency with our Abrasive Blasting Nozzle Wear Gauge Set, designed for quick and accurate assessment of nozzle wear in sizes #6, #7, #8, and #10. Featuring an extended design, this tool allows for measurements without removing the nozzle from its holder and eliminates the need for additional instruments like pencils. Regular use helps detect wear as small as 1/32", ensuring timely nozzle replacements to maintain peak performance.- Measures nozzle sizes: #6, #7, #8, and #10

- Detects wear starting at 1/32"

- Extended length enables in-place measurements without nozzle removal. Simply drop in the applicable gauge into the end of the nozzle and if it goes through, it's time to replace!

- No additional tools required for operation

- Enhances blasting efficiency by identifying worn nozzles promptly

- Durable construction for long-term use

-

- Curved "Banana" Blast Nozzle

- Made from Boron Carbide which is the longest lasting material used for blast nozzles

- Size listed is a #6, which is 3/8" internal diameter

- Has a Medium 3/4" Thread - Requires a special nozzle holder adapter

- Search for “nozzle thread adaptors” to select an adaptor to use with your existing nozzle holder, or contact BlastOne if you want a medium thread nozzle holder.

- Sold Individually

-

GRACO® SPECIAL PURCHASE - NOZZLE FINAL CLEARANCE! These nozzles, originally produced for the Graco EcoQuip series, are top quality, new condition and suitable for any blasting equipment - wet or dry. At 90% off MSRP, these nozzles on final clearance pricing are the cheapest blast nozzles currently on the market, and include the following types:

- General Purpose (contractor thread)

- Hyper Extended Venturi Hi-Performance (contractor thread)

- SST stainless steel jacket (medium thread)

- Double Venturi (contractor thread)

-

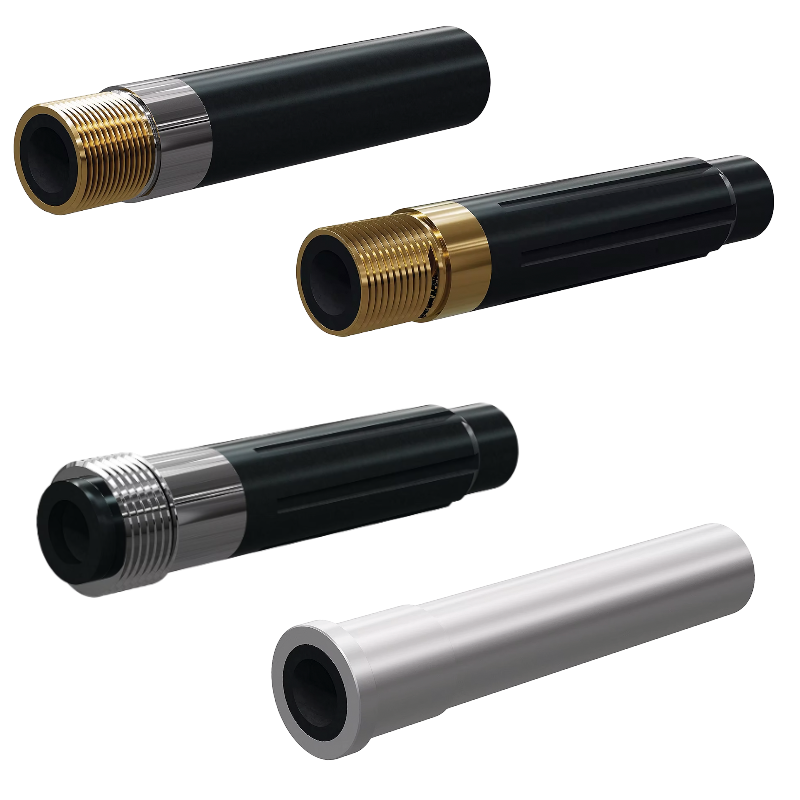

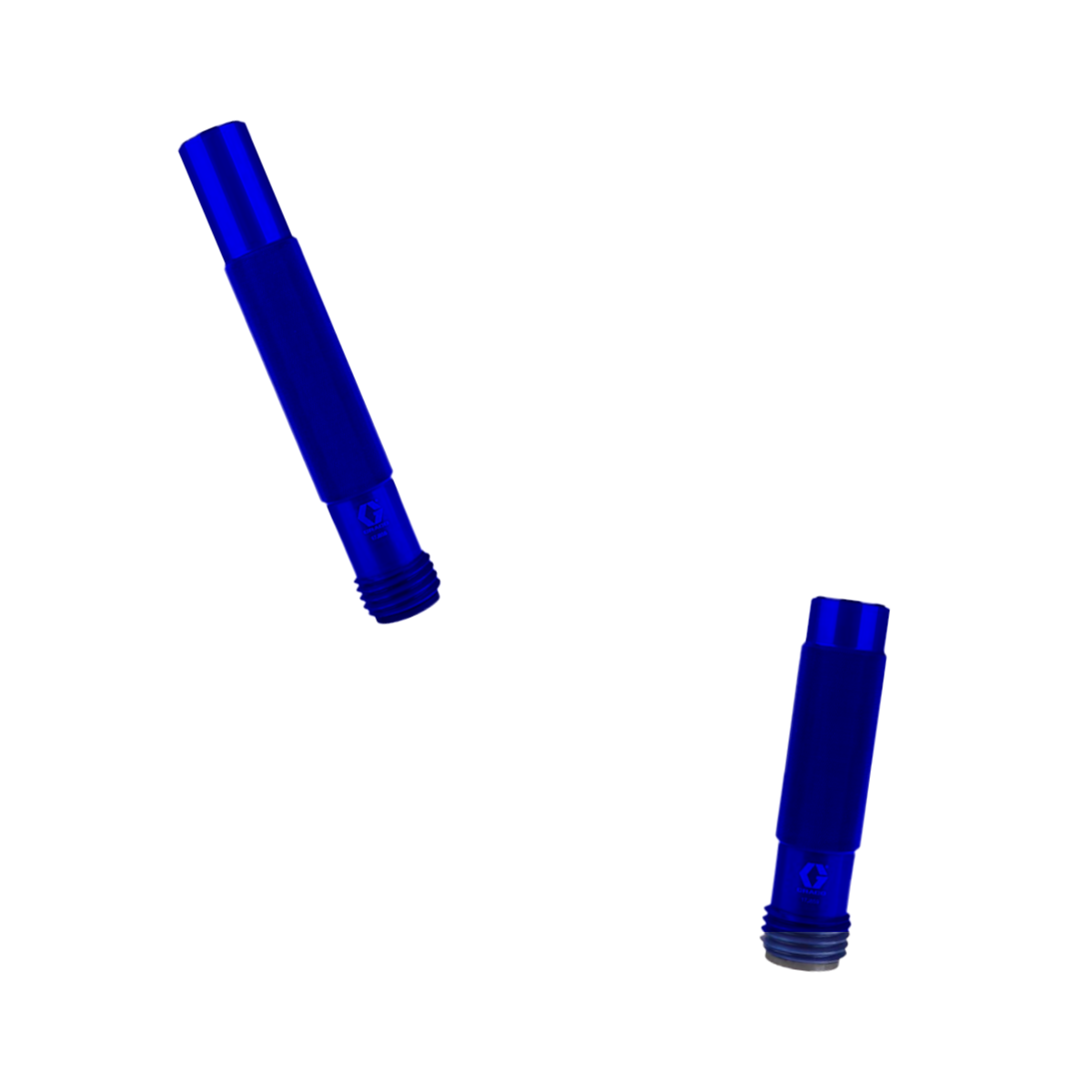

The Blast Ninja nozzle is an option for reducing the noise of blasting in certain applications. It offers price-leading economy for applications where production speeds are not critical. Product details are as follows:

- Sizes. Comes in #4, #5, #6 and #7 orifices.

- Threads. Offered in fine or contractor thread in poly, brass, or aluminum threads.

- Liner options. Available in tungsten carbide or extended-life silicon nitride.

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment