Blasting, UHP & Site Equipment

Showing 571–585 of 621 results

-

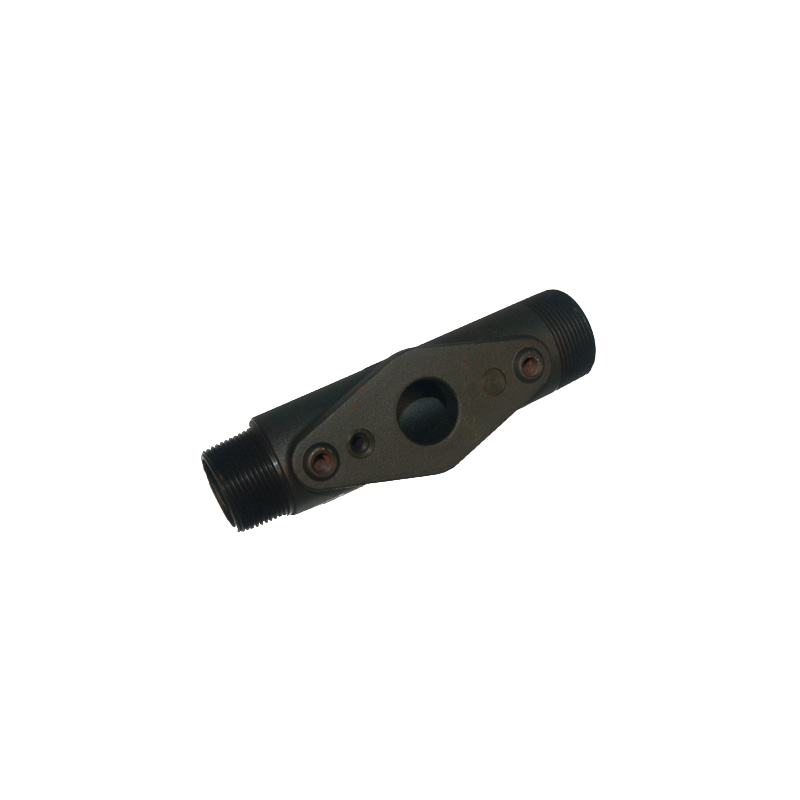

GV214900007

- OEM Replacement Plunger suits Thompson® Valve I

- Wear surface is made of Tungsten Carbide for increased life

- Schmidt® / Axxiom part # is 2149-000-07

GV214900007- OEM Replacement Plunger suits Thompson® Valve I

- Wear surface is made of Tungsten Carbide for increased life

- Schmidt® / Axxiom part # is 2149-000-07

-

BlastOne stocks the Axxiom replacement parts you need to keep your valves operating. These are the MicroValve 2 pipe nipples.

- 1-¼" MNPT x 1-½" MNPT, MPN 2127-007-10

- 1-½" MNPT x 1-½" MNPT, MPN 2127-008-10

- Hardened Steel for extended durability

- Genuine Schmidt / Axxiom Parts

-

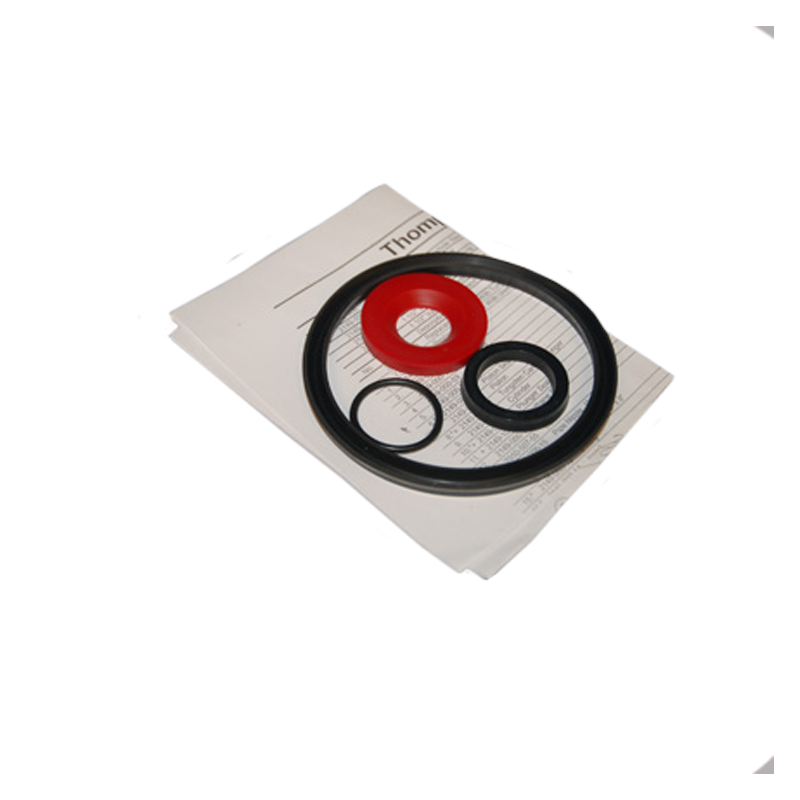

GV214900098

- OEM Seals Kit for the Thompson® Valve I

- Replacement Seals / O-Rings only

- Schmidt® Axxiom part # 2149-000-98

- Includes: GV214900004, GVGV214900006, GV214900010, and GV214900018

GV214900098- OEM Seals Kit for the Thompson® Valve I

- Replacement Seals / O-Rings only

- Schmidt® Axxiom part # 2149-000-98

- Includes: GV214900004, GVGV214900006, GV214900010, and GV214900018

-

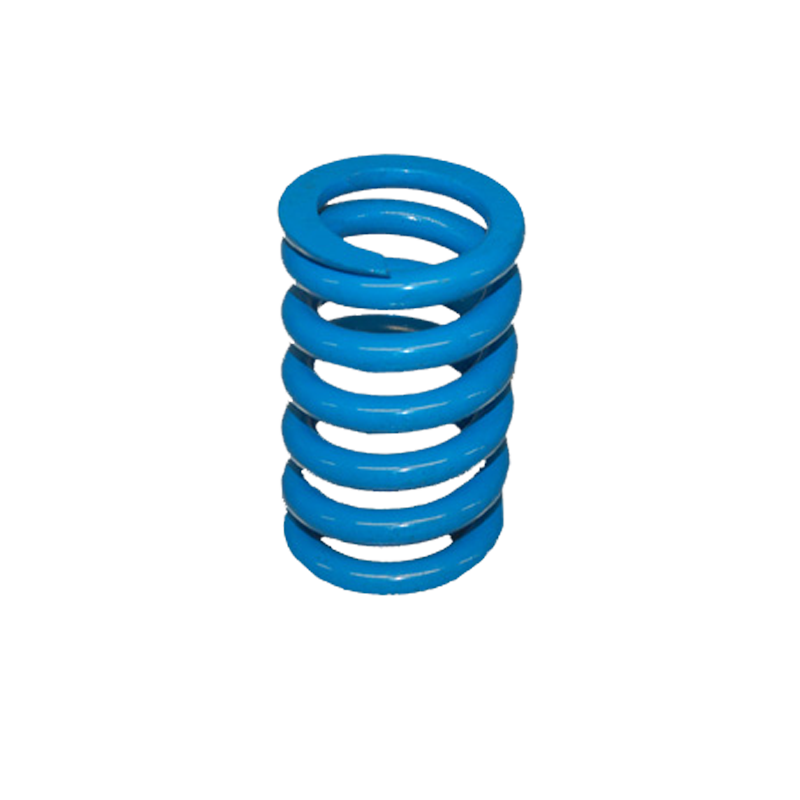

GV214900003

- OEM Replacement Spring for Thompson® Valve I

- Schmidt® / Axxiom part # 2149-000-03

GV214900003- OEM Replacement Spring for Thompson® Valve I

- Schmidt® / Axxiom part # 2149-000-03

-

GV214900010

- OEM Replacement Urethane Seat for Thompson Valve 1

- This is one of the most common wear items, and easily replaced

- Schmidt / Axxiom part # 2149-000-10

GV214900010- OEM Replacement Urethane Seat for Thompson Valve 1

- This is one of the most common wear items, and easily replaced

- Schmidt / Axxiom part # 2149-000-10

-

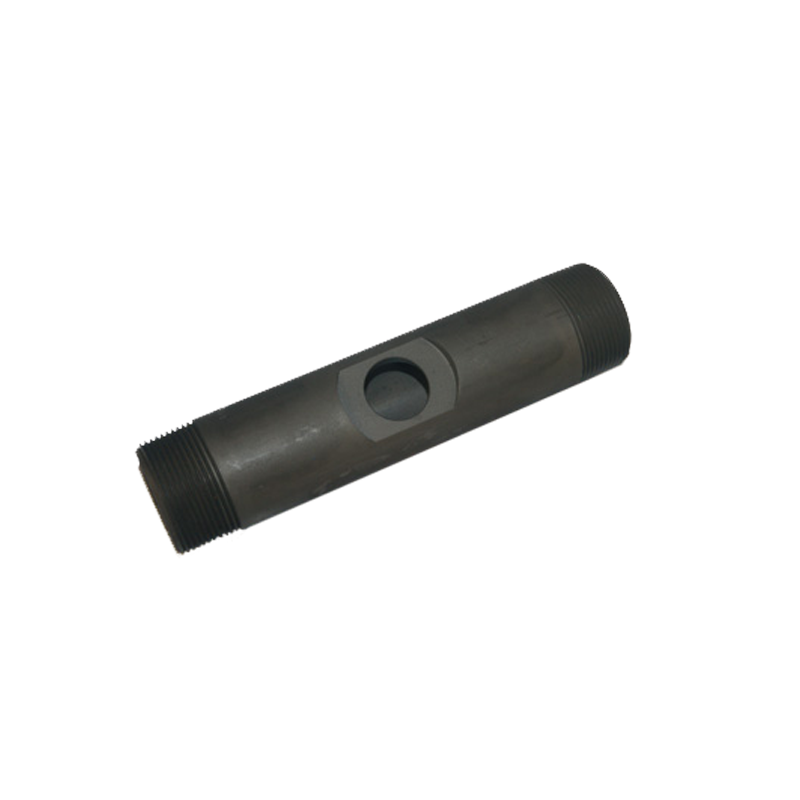

BlastOne has stocks the Axxiom replacement parts you need to keep your valves operating. These are the pipe nipples for the original Thompson I metering valve.

- 1-¼" MNPT x 1-¼" MNPT, MPN 2149-007-15

- 1-½" MNPT x 1-½" MNPT, MPN 2149-008-15

- Hardened Steel for extended durability

- Genuine Schmidt / Axxiom Parts

-

GV215200010

- OEM Urethane Seat suit Thompson Valve 2

- Used with the Tungsten Carbide Sleeve (The most common)

- One of the main signs of wear is air leaking out of the nozzle when you're not blasting but the pot is pressurized

- Schmidt / Axxiom part # 2152-000-10

GV215200010- OEM Urethane Seat suit Thompson Valve 2

- Used with the Tungsten Carbide Sleeve (The most common)

- One of the main signs of wear is air leaking out of the nozzle when you're not blasting but the pot is pressurized

- Schmidt / Axxiom part # 2152-000-10

-

GV215200014

- OEM Replacement Body for Thompson Valve 2

- This houses the Sleeve, Plunger and their accompanying parts, which are not included

- Schmidt / Axxiom part # 2152-000-14

GV215200014- OEM Replacement Body for Thompson Valve 2

- This houses the Sleeve, Plunger and their accompanying parts, which are not included

- Schmidt / Axxiom part # 2152-000-14

-

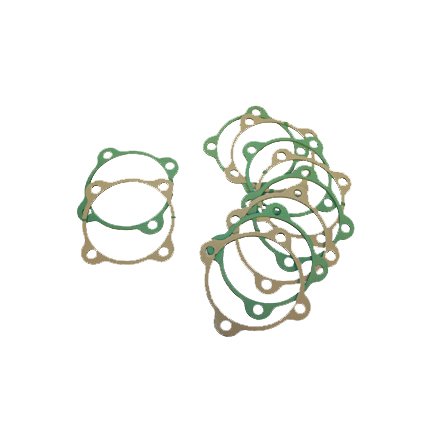

GV215200016

- OEM Replacement Cap Gasket for Thompson Valve II

- Recommend to replace whenever the cap is removed

- Schmidt / Axxiom part # 2152-000-16

- Package of 10 gaskets

GV215200016- OEM Replacement Cap Gasket for Thompson Valve II

- Recommend to replace whenever the cap is removed

- Schmidt / Axxiom part # 2152-000-16

- Package of 10 gaskets

-

GV215200009

- OEM Replacement Cylinder for Thompson Valve 2

- This is the section of body that the cap bolts to and the piston rides in

- Schmidt / Axxiom part # is 2152-000-09

GV215200009- OEM Replacement Cylinder for Thompson Valve 2

- This is the section of body that the cap bolts to and the piston rides in

- Schmidt / Axxiom part # is 2152-000-09

-

GV215200018

- OEM Replacement O-Ring suit Spring Retainer in the Cap

- Schmidt / Axxiom part # 2152-000-18

GV215200018- OEM Replacement O-Ring suit Spring Retainer in the Cap

- Schmidt / Axxiom part # 2152-000-18

-

GV215200021

- OEM Replacement O-Ring suit Schmidt Tungsten Carbide Sleeve

- Schmidt / Axxiom part # 2152-000-21

GV215200021- OEM Replacement O-Ring suit Schmidt Tungsten Carbide Sleeve

- Schmidt / Axxiom part # 2152-000-21

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment