Blasting, UHP & Site Equipment

Showing 31–45 of 617 results

-

BA22856The Clemco Inlet Seal Service Kit (MPN: 22856) provides all necessary components to maintain and repair your MQV inlet seal. This genuine replacement kit ensures precise fit, reliable performance, and extended equipment longevity. Kit Includes:

- Cylinder Cap Gasket

- U-Seal, dual piston lower, 3-½" ID

- U-Seal, dual piston upper, 2-¾" ID

- 4-1/2" OD O-Ring

- 31/64" ID O-Ring

- (2) 1-3/4" O-Rings (replaces original U-Seals)

BA22856The Clemco Inlet Seal Service Kit (MPN: 22856) provides all necessary components to maintain and repair your MQV inlet seal. This genuine replacement kit ensures precise fit, reliable performance, and extended equipment longevity. Kit Includes:- Cylinder Cap Gasket

- U-Seal, dual piston lower, 3-½" ID

- U-Seal, dual piston upper, 2-¾" ID

- 4-1/2" OD O-Ring

- 31/64" ID O-Ring

- (2) 1-3/4" O-Rings (replaces original U-Seals)

-

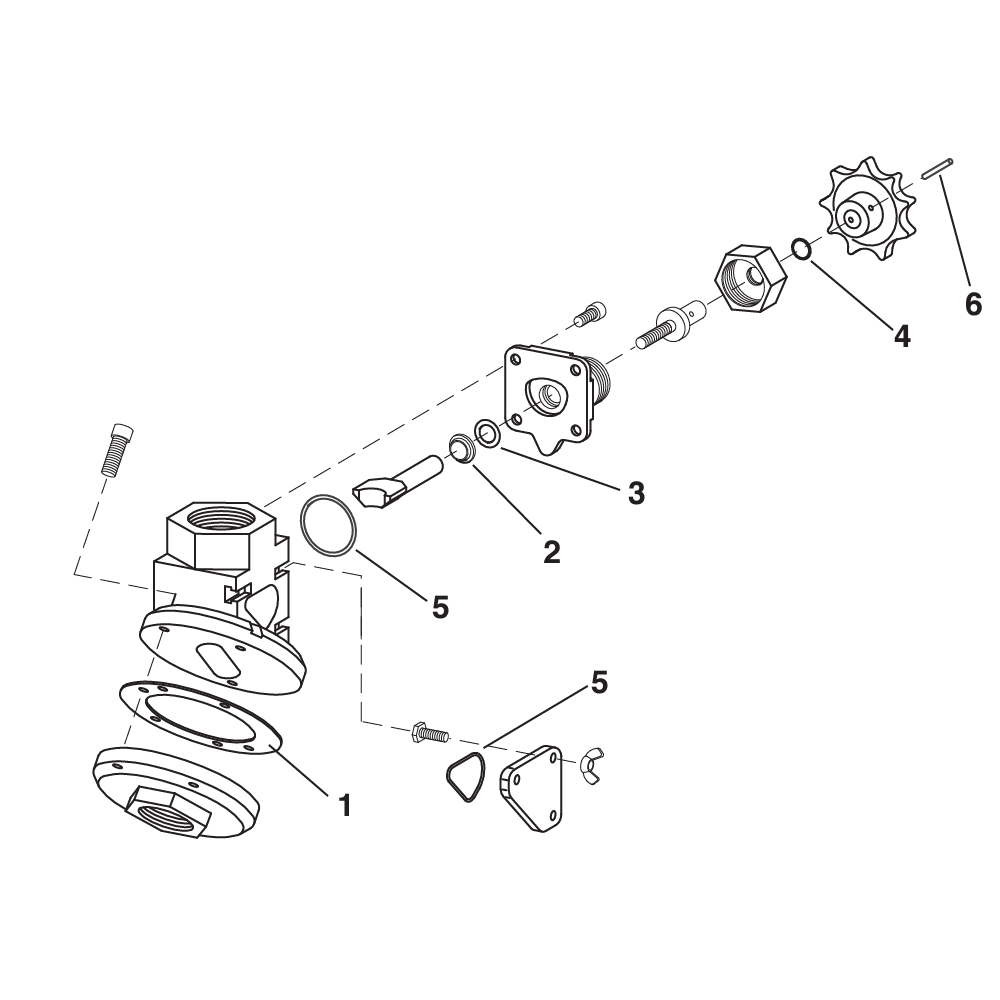

GV22620The Clemco Inspection Plate Clean-Out Cover (MPN: 22620) is a genuine replacement part for the Clemco Manual Quantum Valve (MQV). Labeled as #4 on the parts diagram, this cover ensures a secure seal and easy access for maintenance and cleaning. Key Features:

- Replacement inspection plate clean-out cover for Clemco MQV valve.

- Labeled as #4 on the MQV parts diagram for easy identification.

- Ensures a tight seal to maintain system performance and prevent leaks.

- Allows easy access for inspection, maintenance, and cleaning.

- Genuine Clemco part for guaranteed quality and compatibility.

GV22620The Clemco Inspection Plate Clean-Out Cover (MPN: 22620) is a genuine replacement part for the Clemco Manual Quantum Valve (MQV). Labeled as #4 on the parts diagram, this cover ensures a secure seal and easy access for maintenance and cleaning. Key Features:- Replacement inspection plate clean-out cover for Clemco MQV valve.

- Labeled as #4 on the MQV parts diagram for easy identification.

- Ensures a tight seal to maintain system performance and prevent leaks.

- Allows easy access for inspection, maintenance, and cleaning.

- Genuine Clemco part for guaranteed quality and compatibility.

-

The Clemco Manway / Handway Replacement Parts include genuine replacement gaskets and inspection door assemblies for abrasive blasting equipment. Available in all current and legacy model sizes, these parts ensure a secure seal and reliable performance for your Clemco system.

Key Features:

- Replacement **inspection door gaskets** for Clemco equipment.

- Replacement **inspection door assemblies** in standard sizes:

- 3" x 4"

- 4" x 6"

- 6" x 8"

- 14" x 18"

- Provides a tight, leak-proof seal for efficient operation.

- Crafted from durable materials to withstand abrasive blasting environments.

- Genuine Clemco parts for compatibility and reliable performance.

-

DM21731The Clemco Millennium Valve Outlet Segment, Muffler (MPN: 21731) is a genuine replacement part designed to maintain and restore the performance of your Clemco Millennium Valve. This component ensures smooth operation and efficient air exhaust for abrasive blasting systems. Key Features:

- Replacement valve outlet segment, muffler for Clemco Millennium Valve.

- Engineered for efficient air exhaust and noise reduction.

- Durable construction to withstand abrasive blasting conditions.

- Genuine Clemco part ensures precise fit and reliable performance.

- Essential for maintaining valve efficiency and prolonging system life.

DM21731The Clemco Millennium Valve Outlet Segment, Muffler (MPN: 21731) is a genuine replacement part designed to maintain and restore the performance of your Clemco Millennium Valve. This component ensures smooth operation and efficient air exhaust for abrasive blasting systems. Key Features:- Replacement valve outlet segment, muffler for Clemco Millennium Valve.

- Engineered for efficient air exhaust and noise reduction.

- Durable construction to withstand abrasive blasting conditions.

- Genuine Clemco part ensures precise fit and reliable performance.

- Essential for maintaining valve efficiency and prolonging system life.

-

GV22763The Clemco MQV Metering Plate & Shaft (MPN: 22763) is a genuine replacement part designed for the Clemco Manual Quantum Valve (MQV). Labeled as #9 on the system diagram, this component ensures precise abrasive media flow control and restores the performance of your metering valve. Key Features:

- Replacement metering plate and shaft for Clemco MQV.

- Labeled **#9** in the Clemco MQV diagram for easy identification.

- Genuine Clemco part ensures compatibility and reliable performance.

- Durable construction for long-lasting service in abrasive blasting environments.

- Essential for maintaining precise abrasive metering and system efficiency.

GV22763The Clemco MQV Metering Plate & Shaft (MPN: 22763) is a genuine replacement part designed for the Clemco Manual Quantum Valve (MQV). Labeled as #9 on the system diagram, this component ensures precise abrasive media flow control and restores the performance of your metering valve. Key Features:- Replacement metering plate and shaft for Clemco MQV.

- Labeled **#9** in the Clemco MQV diagram for easy identification.

- Genuine Clemco part ensures compatibility and reliable performance.

- Durable construction for long-lasting service in abrasive blasting environments.

- Essential for maintaining precise abrasive metering and system efficiency.

-

BA22898The Clemco Plunger Tip Service Kit for Millennium Valve (MPN: 22898) provides all the essential components to maintain and repair your Clemco Millennium Valve. This genuine replacement kit ensures optimal valve performance and includes only the parts labeled "++." Key Features:

- Designed specifically for Clemco Millennium Valves.

- Includes parts labeled "++" for efficient servicing.

- Genuine Clemco replacement parts ensure compatibility and reliability.

- Helps maintain peak valve performance and extend service life.

- Easy-to-use kit reduces downtime during maintenance.

BA22898The Clemco Plunger Tip Service Kit for Millennium Valve (MPN: 22898) provides all the essential components to maintain and repair your Clemco Millennium Valve. This genuine replacement kit ensures optimal valve performance and includes only the parts labeled "++." Key Features:- Designed specifically for Clemco Millennium Valves.

- Includes parts labeled "++" for efficient servicing.

- Genuine Clemco replacement parts ensure compatibility and reliability.

- Helps maintain peak valve performance and extend service life.

- Easy-to-use kit reduces downtime during maintenance.

-

The Clemco Pop-Up Guides are OEM replacement parts designed for all Clemco pop-up type blasting pots. Available in multiple sizes, these internal pop-up guides ensure optimal performance and longevity for your Clemco equipment. Key Features:

- Designed for all Clemco units with pop-up assemblies

- Available size options:

- 1-1/4" x 5" toe

- 1-1/4" x 6" toe

- 1-1/4" x 6-1/2" toe

- 1-1/4" x 9-1/2" toe

- Made from durable materials for extended service life.

- Authentic Clemco replacement parts to maintain equipment reliability.

- Easy to install for minimal downtime.

-

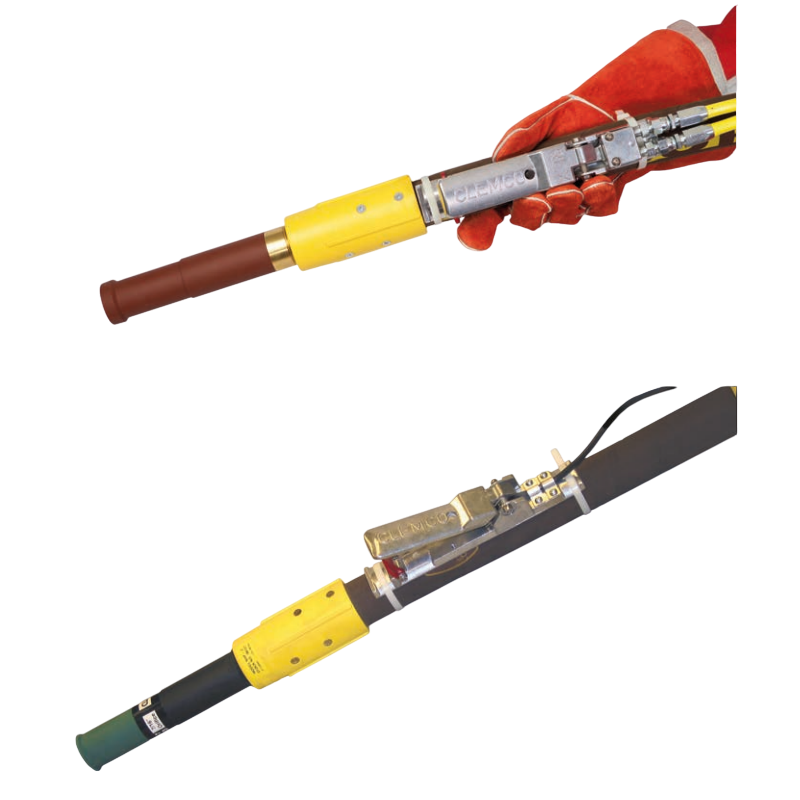

Keep abrasive blasting operators safe with Clemco Deadman Handles. These are essential safety components for blasting operations, meeting OSHA regulations for remote control systems. Available in pneumatic and electric configurations, these handles ensure safe blasting control by automatically de-energizing the blast hose when deactivated, or when dropped accidentally. Key Features:

- Available in pneumatic or electric configurations to suit different blasting setups.

- Complies with OSHA regulations for remote blasting control systems.

- Pneumatic handles operate effectively with up to 100 feet of twinline control hose.

- Electric handles operate efficiently at distances up to 500 feet with specialized cables for extended ranges. Electric handles have the added advantage of never freezing up during cold weather use.

- Spring-loaded lever mechanism prevents accidental activation.

- Compatible with Clemco remote control valves and other system components.

- Durable construction for reliable performance in harsh environments.

-

BA22854The Clemco Service Kit for MQV Metering Segment (MPN: 22854) provides all necessary components to maintain and repair your MQV metering segment. This genuine replacement kit ensures precise fit, reliable performance, and extended equipment longevity. Kit Includes:

- Flange Gasket

- Wiper Seal

- 3/4" O-Ring

- 5/8" O-Ring

- 1-1/2" O-Ring

- Roll Pin

BA22854The Clemco Service Kit for MQV Metering Segment (MPN: 22854) provides all necessary components to maintain and repair your MQV metering segment. This genuine replacement kit ensures precise fit, reliable performance, and extended equipment longevity. Kit Includes:- Flange Gasket

- Wiper Seal

- 3/4" O-Ring

- 5/8" O-Ring

- 1-1/2" O-Ring

- Roll Pin

-

GV215300014The Thompson II XL Replacement Body (MPN: 2153-000-14) is a genuine replacement component designed to restore and maintain the performance of your Thompson II XL abrasive metering valve. This durable body includes a sleeve pin for seamless installation and ensures reliable operation. Key Features:

- Precision-engineered replacement body for the Thompson II XL abrasive metering valve.

- Includes sleeve pin for a complete and easy installation.

- Constructed from durable materials to withstand demanding abrasive blasting environments.

- Genuine part ensures perfect compatibility and reliable performance.

- Restores functionality and extends the lifespan of your Thompson II XL system.

GV215300014The Thompson II XL Replacement Body (MPN: 2153-000-14) is a genuine replacement component designed to restore and maintain the performance of your Thompson II XL abrasive metering valve. This durable body includes a sleeve pin for seamless installation and ensures reliable operation. Key Features:- Precision-engineered replacement body for the Thompson II XL abrasive metering valve.

- Includes sleeve pin for a complete and easy installation.

- Constructed from durable materials to withstand demanding abrasive blasting environments.

- Genuine part ensures perfect compatibility and reliable performance.

- Restores functionality and extends the lifespan of your Thompson II XL system.

-

The Clemco Blast Cabinet Window Gaskets are durable, high-performance OEM parts designed to create a secure, airtight seal for Clemco blast cabinet and blast room windows. Sold by the foot, this gasket prevents dust, media, and debris from escaping during abrasive blasting. Features:

- Application: Designed for the cabinet side, not the window itself.

- Secure Seal: Prevents air leaks and ensures a clean blasting environment.

- Durable Material: Built to withstand abrasive blasting conditions.

- Sizing Options: Available in 5/16" x 3/4", 5/32" x 3/4", and 5/8" x 2-1/2".

- Usage: Typically, 6 feet are required to seal a standard cabinet. Sold by the foot for customizable lengths.

-

- Swiveling nut for easy fit-up - nut 'locks up' rigid when tightened (NPTFSW)

- Steel

- 4:1 Safety Factor

-

Clemco Industries is the world's largest manufacturer of air-powered blasting equipment. It is over 80 years old, being founded in 1941. Clemco offers two series of blast machines - the Classic and the Contractor Pots. While both are designed for industrial applications, there are a few primary differences which are shown in the table below:

Classic Series Contractor Series Controls Pneumatic standard. Electric only by special quote. Pneumatic or Electric Control Valves Separate Inlet / Outlet valves. Millennium or Quantum (combination inlet/outlet) Design Highlights Portable w/2 wheels. Improved portability (4 wheels) and protection (built-in tube steel handles around valves). Built-in storage for manuals. Improved access to hose fittings. Nomenclature 2452 Std. 6.0cf 2443 Lo 6.0cf (both 24" dia) 2020 4.0cf (20" diameter) 2024 6.0cf (24" diameter) Other features, such as pressure-hold or pressure-release deadmans, accessory packages, etc. are available on either series. The economy Classic blast pot with the FSV (flat sand valve) is the best-selling Clemco blast machine. The Contractor series offers more time saving and protection features.

This Clemco Blast Machine group includes the 4 and 6 cubic foot versions.

-

Snakebite. The world's quietest blast nozzle!

BlastOne's SnakeBite XQ Silenced Blast Nozzle is engineered to be the world's quietest blast nozzle, prioritizing both operator safety and comfort. This innovative nozzle, exclusively designed by BlastOne, significantly reduces noise levels while enhancing performance, making it an essential tool for professionals in the blasting industry.- Up to 16dBA noise reduction

- Up to 45% less thrust compared to standard blast nozzles, greatly reducing operator fatigue and improving safety at heights

- Improved nozzle geometry

- New technology quick-connect nozzle silencer

- Durable and lightweight Silicon Nitride nozzle and silencer liner

- Slim ergonomic nozzle jacket

- Available with Contractor threads only, which are recommended. If Fine thread nozzle holders are a site requirement, use a Nozzle Thread Adaptor.

- 2 versions available

- Standard Pressure Nozzle effective between 90-110 psi

- Low Pressure (LPS) Nozzle effective between 70-90 psi

- FREE TRIAL AVAILABLE

- Click for Buying Guide

-

All the power. Half the size!

BlastOne's SnakeBite Flex Silenced Blast Nozzle is the ultimate solution for blasting in tight spaces without compromising power or performance. Exclusively engineered by BlastOne, this compact nozzle delivers all the benefits of the SnakeBite family, including noise reduction and reduced operator fatigue, while being small enough to navigate hard-to-reach areas with ease.- Up to 16dBA noise reduction

- Up to 45% less fatigue compared to standard blast nozzles

- Improved nozzle geometry

- New technology quick-connect nozzle silencer

- Durable and lightweight Silicon Nitride nozzle and silencer liner

- Slimline ergonomic nozzle jacket

- Standard contractor nozzle inlet thread

- 2 versions available

- Standard Pressure Nozzle effective between 90-110 psi

- Low Pressure (LPS) Nozzle effective between 70-90 psi

- FREE TRIAL AVAILABLE

Act quick! Limited supply.

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment