Blasting, UHP & Site Equipment

Showing 331–345 of 607 results

-

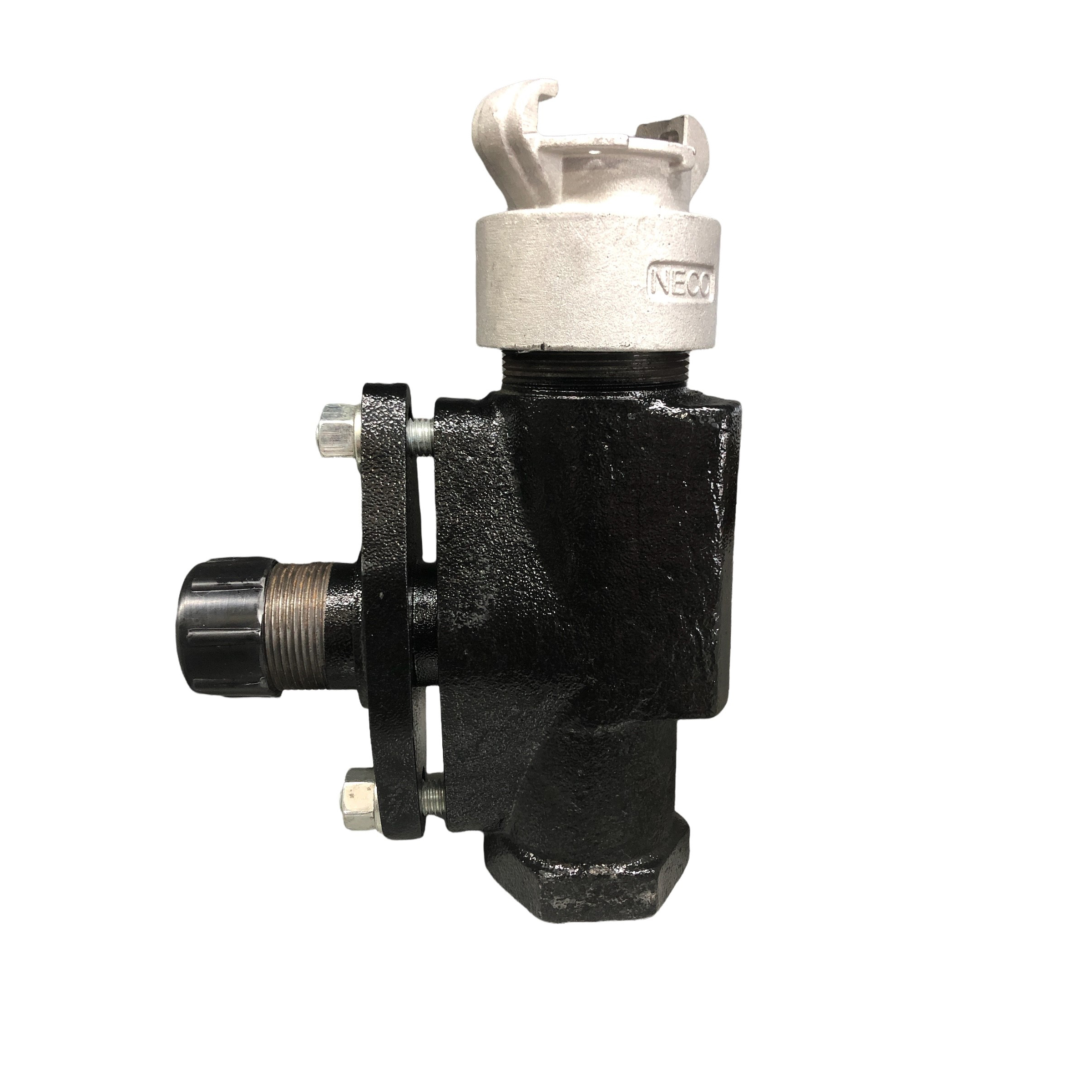

GV02427

- The Flat Sand Valve is the classic Clemco abrasive metering valve used for sandblasting for nearly 100 years.

- Used in most new Classic blast machine pots

- The FSV is simple and economical and provides abrasive metering control for expendable mineral abrasives and slags (not recommended for steel grit or aluminum oxide).

- The valve uses a simple lever and keyslot to control the flow of abrasive from the blast pot into the blast hose

- It is good practice to keep a complete spare valve on hand to use when needed, repairing the worn valve at a convenient later time.

- Genuine Clemco Part Number 02427

GV02427- The Flat Sand Valve is the classic Clemco abrasive metering valve used for sandblasting for nearly 100 years.

- Used in most new Classic blast machine pots

- The FSV is simple and economical and provides abrasive metering control for expendable mineral abrasives and slags (not recommended for steel grit or aluminum oxide).

- The valve uses a simple lever and keyslot to control the flow of abrasive from the blast pot into the blast hose

- It is good practice to keep a complete spare valve on hand to use when needed, repairing the worn valve at a convenient later time.

- Genuine Clemco Part Number 02427

-

The Flat Sand Valve is legacy metering technology, where the metering is performed by sliding a lever to open and close the abrasive port. It is simple in design and relatively inexpensive, but has a few limitations. Details as follows:

- Slide-plate metering design, controlled by lever

- 1 1/4" (32 mm) ports

- Features side cleanout-inspection port

- Available with or without outlet nipple and Y-piece (Optional rubber lined nipple is available to extend nipple life.)

- The major limitations are:

- Not recommended for use with metallic abrasives

- The slide plate/lever design does not provide effective fine metering control. Typically this results in over consumption of media. For low-volume blasting using inexpensive media, this may not be an issue.

-

GVDNV100

- HFSTC3 blast coupling included

- Designed for use with coarse metallic abrasives

- Heavy cast iron construction

- Not recommended for use with fine abrasives

- 1 1/2" NPT female thread air connection

- Recommended upgrade: MicroValve 3

GVDNV100- HFSTC3 blast coupling included

- Designed for use with coarse metallic abrasives

- Heavy cast iron construction

- Not recommended for use with fine abrasives

- 1 1/2" NPT female thread air connection

- Recommended upgrade: MicroValve 3

-

SBMGP

- Pre-engineered to minimize costs and ensure quick set up

- Typical max part size (to be blasted): 5’ x 3’ x 8’ (W x H x L)

- Blasting chamber with set of double-doors

- Dust tight, high-powered LED lights in ceiling

- Shovel-in hopper, elevator and air classifier for basic abrasive recovery/recycling

- Includes abrasive storage hopper and high-performance sandblasting machine

- Separate personnel side access door (optional)

SBMGP- Pre-engineered to minimize costs and ensure quick set up

- Typical max part size (to be blasted): 5’ x 3’ x 8’ (W x H x L)

- Blasting chamber with set of double-doors

- Dust tight, high-powered LED lights in ceiling

- Shovel-in hopper, elevator and air classifier for basic abrasive recovery/recycling

- Includes abrasive storage hopper and high-performance sandblasting machine

- Separate personnel side access door (optional)

-

SBMGI

- High quality, acoustically insulated steel sandwich panel construction

- Ideal for consistent blasting production (1 operator, 20-40 hrs/week)

- Various material handling options: product carts, forklift loading, manual handling

- Partial or Full-floor abrasive recovery system

- Airwash abrasive cleaner for grit recycling with vibrating screen for trash removal

- Reverse pulse cartridge dust collector

- Typical size ranging from:

- 10’ W x 10’ H x 10’ L (small)

- 22’ W x 22’ H x 100’ L (large)

SBMGI- High quality, acoustically insulated steel sandwich panel construction

- Ideal for consistent blasting production (1 operator, 20-40 hrs/week)

- Various material handling options: product carts, forklift loading, manual handling

- Partial or Full-floor abrasive recovery system

- Airwash abrasive cleaner for grit recycling with vibrating screen for trash removal

- Reverse pulse cartridge dust collector

- Typical size ranging from:

- 10’ W x 10’ H x 10’ L (small)

- 22’ W x 22’ H x 100’ L (large)

-

SBMGSHeavy Duty Blast Room can be designed for use with any steel or heavy machinery manufacturers, refinishing facilities, for oil and gas components, or in job shops. The "General Purpose Custom Engineered Blast Rooms and Facilities" (SKU: SBMGS) are heavy-duty, long-term sandblasting solutions. Designed for diverse industrial needs, these rooms feature robust steel panels, advanced abrasive recovery systems, and extensive customizability. Ideal for consistent operations seeking a controlled blasting environment.SBMGSHeavy Duty Blast Room can be designed for use with any steel or heavy machinery manufacturers, refinishing facilities, for oil and gas components, or in job shops. The "General Purpose Custom Engineered Blast Rooms and Facilities" (SKU: SBMGS) are heavy-duty, long-term sandblasting solutions. Designed for diverse industrial needs, these rooms feature robust steel panels, advanced abrasive recovery systems, and extensive customizability. Ideal for consistent operations seeking a controlled blasting environment.

-

SBMGRDesigned to improve throughput and lower operating costs in Railcar Facilities, these Blast Rooms are suitable to railcar relining, refurb, or new build.SBMGRDesigned to improve throughput and lower operating costs in Railcar Facilities, these Blast Rooms are suitable to railcar relining, refurb, or new build.

-

SBMGWThese blast rooms are designed to improve flow in a Wind Tower manufacturing facility, and can be made to handle both internal and exterior blast, with nearly any level of automation.SBMGWThese blast rooms are designed to improve flow in a Wind Tower manufacturing facility, and can be made to handle both internal and exterior blast, with nearly any level of automation.

-

SBMGZ

- Custom designed blasting and painting facilities, sized as large as application requires

- Ideal for new construction and repair, for vessels of all type and size

- Available configurations:

- Hybrid blast/paint hall - single hall for both operations at different times

- 2 separate halls - each single-purpose hall dedicated to blasting or painting

- Available with completely controllable environmental conditions to meet required specifications

- Compatible with abrasive recovery and recycling equipment with many available configurations

SBMGZ- Custom designed blasting and painting facilities, sized as large as application requires

- Ideal for new construction and repair, for vessels of all type and size

- Available configurations:

- Hybrid blast/paint hall - single hall for both operations at different times

- 2 separate halls - each single-purpose hall dedicated to blasting or painting

- Available with completely controllable environmental conditions to meet required specifications

- Compatible with abrasive recovery and recycling equipment with many available configurations

-

SBMGT

- Permanent or temporary mounting systems

- Ideal for setting up temporary blasting/painting facilities

- Supplied in modular kit for simple, quick installation (under a week)

- Fully relocatable — easy to install and dismantle

- 100% Waterproof design

- Wind rating as per local requirements

- No concrete foundation necessary

- Compatible with optional abrasive recovery and dust collection equipment

SBMGT- Permanent or temporary mounting systems

- Ideal for setting up temporary blasting/painting facilities

- Supplied in modular kit for simple, quick installation (under a week)

- Fully relocatable — easy to install and dismantle

- 100% Waterproof design

- Wind rating as per local requirements

- No concrete foundation necessary

- Compatible with optional abrasive recovery and dust collection equipment

-

EB500FOR RENTAL OR PURCHASE

- Ideal for horizontal steel surfaces and marine maintenance

- Center-fed blast wheel design for efficient abrasive propulsion

- Closed-circuit blasting reduces dust and recovery time

- Modular design for easy access in restricted areas

- Blasting speed between 215-377 sq.ft / 20-35 m² per hour

- 15 hp, 460 v, 32 amp, 3-phase power requirements

- 827 lbs./350 kgs weight

- 19"/600 mm manway compatible

- 13¾″/350 mm blasting pattern width

- Compatible with Blastrac EBDC-23 dust collector/vacuum

EB500FOR RENTAL OR PURCHASE- Ideal for horizontal steel surfaces and marine maintenance

- Center-fed blast wheel design for efficient abrasive propulsion

- Closed-circuit blasting reduces dust and recovery time

- Modular design for easy access in restricted areas

- Blasting speed between 215-377 sq.ft / 20-35 m² per hour

- 15 hp, 460 v, 32 amp, 3-phase power requirements

- 827 lbs./350 kgs weight

- 19"/600 mm manway compatible

- 13¾″/350 mm blasting pattern width

- Compatible with Blastrac EBDC-23 dust collector/vacuum

-

EB350FOR RENTAL OR PURCHASE

- The Blastrac EBE 350 is designed for blasting horizontal surfaces

- It is easily dissembled and reassembled for limited access projects such as a storage tank.

- Parts will fit through a 19" Man way

- Blasting Pattern Width of 13-3/4"

- Other Brands and Sizes available - Call us for pricing

EB350FOR RENTAL OR PURCHASE- The Blastrac EBE 350 is designed for blasting horizontal surfaces

- It is easily dissembled and reassembled for limited access projects such as a storage tank.

- Parts will fit through a 19" Man way

- Blasting Pattern Width of 13-3/4"

- Other Brands and Sizes available - Call us for pricing

-

RUBVD223015BlastOne has the parts needed to keep your VertiDrive equipment running. This is the ESCON 70/10 Motor Controller CB4.0.RUBVD223015BlastOne has the parts needed to keep your VertiDrive equipment running. This is the ESCON 70/10 Motor Controller CB4.0.

-

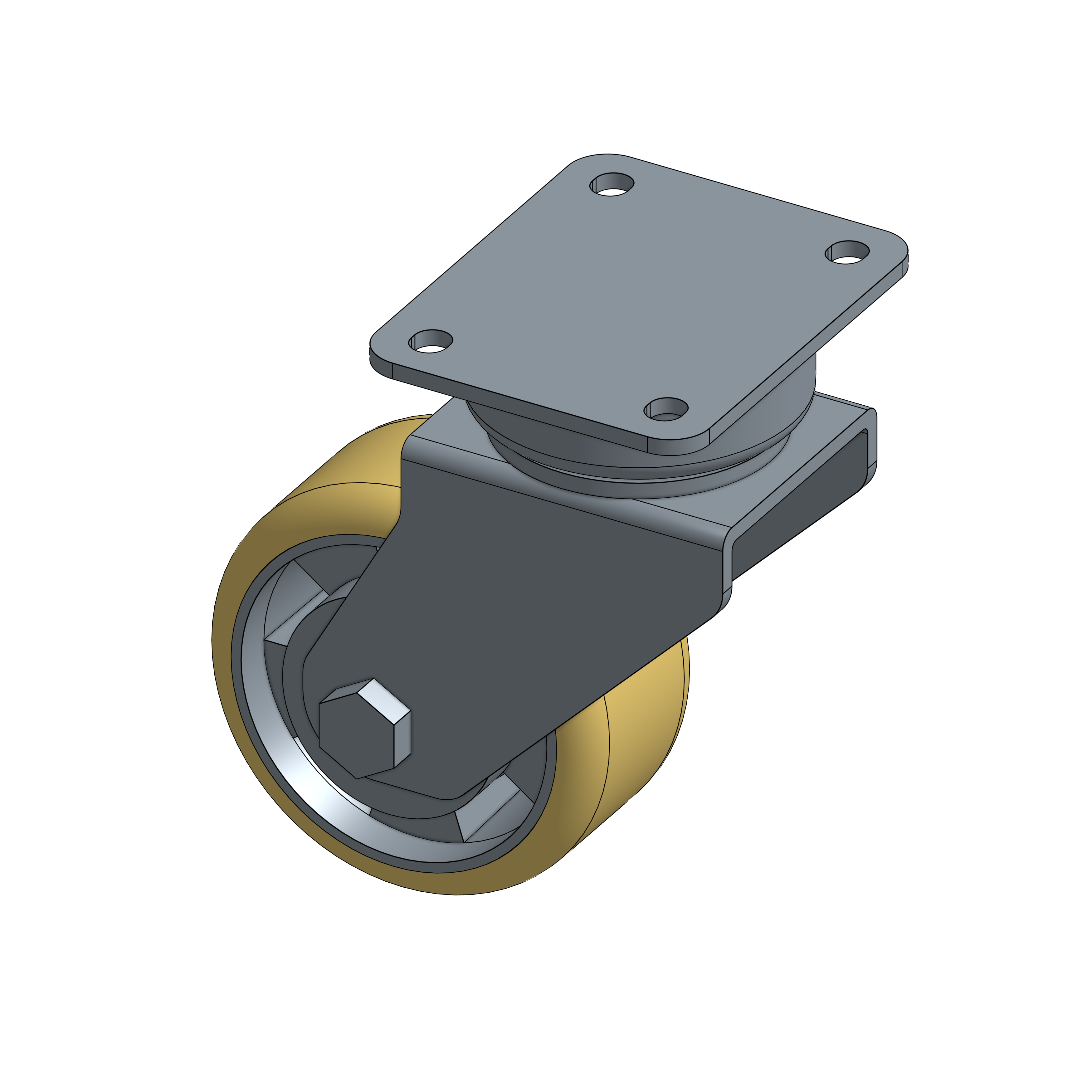

RUBVD113531BlastOne has the parts needed to keep your VertiDrive equipment running. This is the Castor Wheel.RUBVD113531BlastOne has the parts needed to keep your VertiDrive equipment running. This is the Castor Wheel.

-

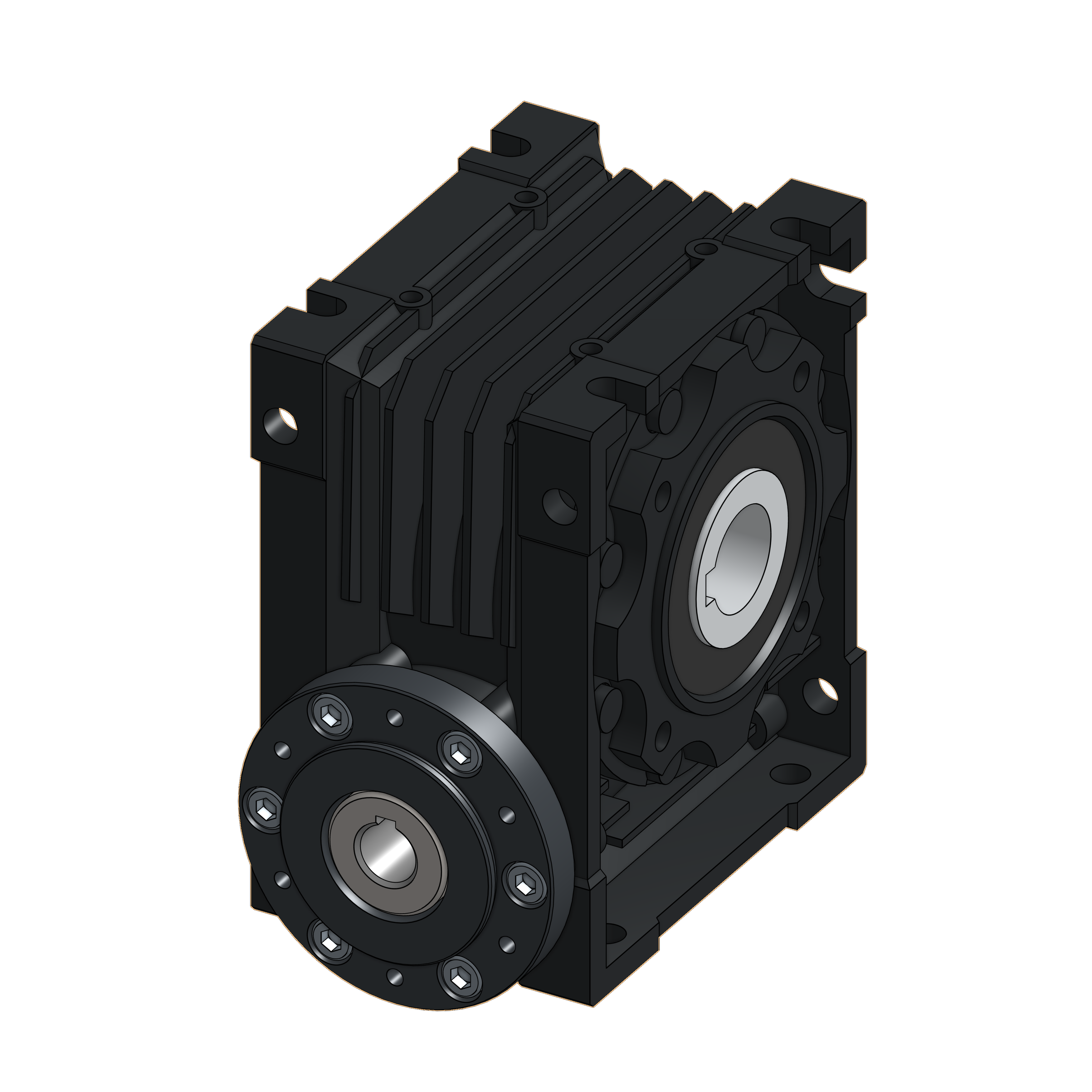

RUBVD322074BlastOne has the parts needed to keep your Vertidrive equipment running. This is the Gearbox 050 with Flange.RUBVD322074BlastOne has the parts needed to keep your Vertidrive equipment running. This is the Gearbox 050 with Flange.

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment