Blasting, UHP & Site Equipment

Showing 301–315 of 607 results

-

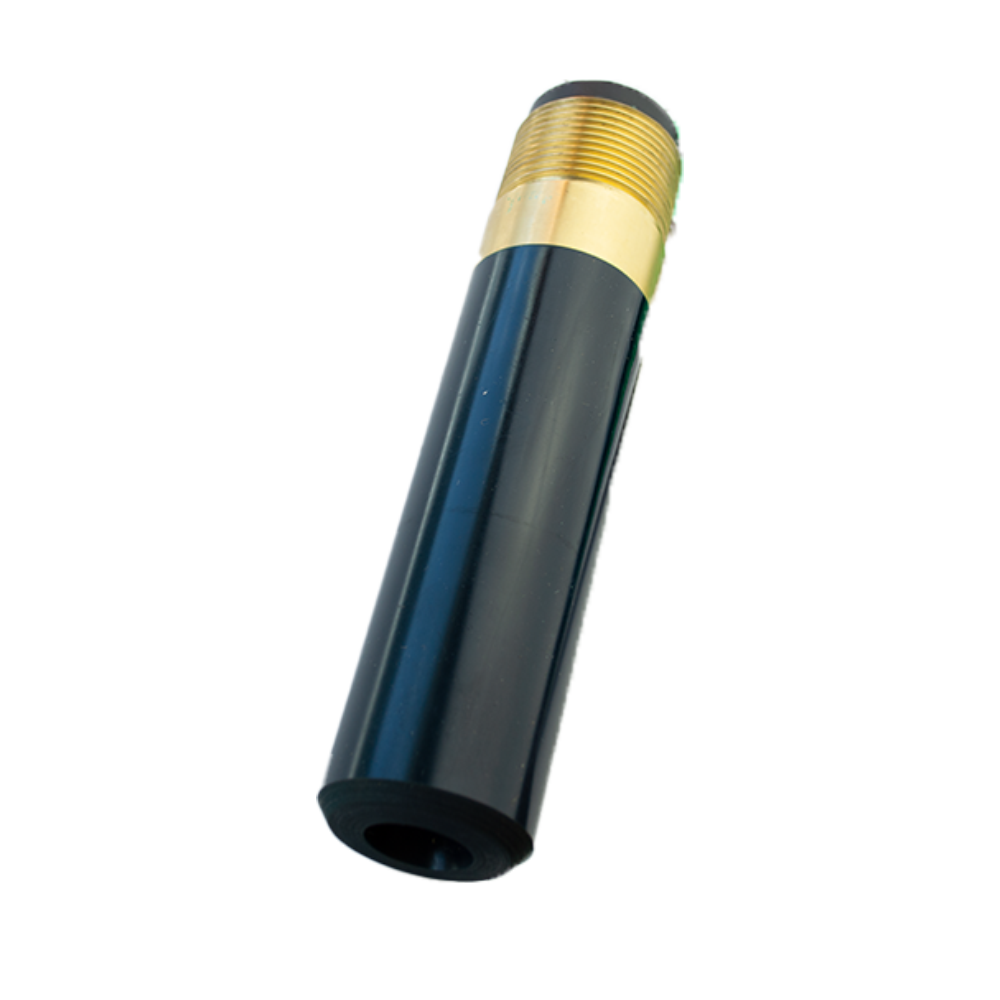

- 2-claw threaded coupling for metering valve outlet, to enable connection of blast hose

- Supplied with HFGMRLP coupling gasket fitted

- For Aluminum, Brass, and Steel, use HFCLP1 thin safety lock pins - purchase separately

- Nylon is supplied with HFGPCG gasket fitted and contains an integral springlock pin

- 2 types available - Standard and MegaMax.

- Note: MegaMax and Standard couplings require an adapter to fit together.

- MegaMax couplings are Full-Flow, designed to remove the air restrictions caused by standard couplings, and increases the PSI available to the nozzle. The increased PSI is mostly beneficial when doing high-production blasting using 1.5" or 2" ID Blast Hoses.

- These are threaded couplings (threaded fittings) designed for metering valve outlets only. Unthreaded QC couplings are used on blast hoses, and can be found HERE.

- Note: 1 1/4" threaded couplings can also be used as Quick-couple type nozzle holders for fine thread nozzles.

- Industry Size Commonly Referred to as SB1, SB-1, SB2, SB-2

-

The 4-Claw Fittings (aka Crowsfoot Couplings) provides a reliable and quick connection for MegaFlow Bull / Air Hoses in industrial applications. Built from plated steel, this coupling is rated for 150 psi and is designed for use with claw bolt clamps and HFCLP2 lock pins for enhanced safety. Each fitting is supplied with a rubber gasket. Quantity discounts available.

Key Product Features:

- 4-Claw (Crowsfoot) coupling for quick connections between bull hoses and equipment.

- Rated for 150 psi; not intended for steam use.

- Compatible with 1-1/4" through 2" ID bull hoses.

- Requires HFCLP2 lock pins and whipchecks to ensure secure connections.

- Durable steel construction for high-pressure industrial use.

- Replacement 4-claw gaskets and quantity discounts available.

-

- Heavy Duty Spud fitting assembly for MegaFlow Bull Air Hose

- Includes Hose Tail (aka Boss® Ground Joint Stem) and Boss® Wing Nut. A hammer is used on the wing nut to tighten it.

- Rugged plated steel construction

- Recommended by BlastOne as the preferred Bull hose fitting – safer than 4-claw

- Gasket-less, low maintenance design. No lock-pins required.

- Safety requires bull hose bolt clamps to secure to the air hose by a special installation procedure

- Sold Individually with quantity discounts available

- Genuine Parts – manufactured by Dixon

-

- Heavy Duty Spud Fittings for MegaFlow Bull / Air Hose to connect bull hose to equipment, or to connect two bull hoses

- Also known as Boss® Ground Joint Fittings, this selection is made of heavy plated Iron

- Recommended by BlastOne as the preferred Bull hose fitting as they are inherently safer than 4-claw fittings

- Sold Individually with Mix/Match quantity discounts available

- Genuine Parts - Manufactured by Dixon

-

- 30 Day Money Back Guarantee | Free Returns

- Industry standard coupling for use with air supply hose

- Rugged steel construction

- Quarter-turn quick action connector

- Supplied with 3/4" I.D. bore gaskets fitted

- Use HF CLP-1 or HF CLP-2 Lock Pin - (not included)

- Available with hose tail, male threads, or female threads

- Sold individually

-

General purpose air connection fittings

- This is the Reducing Bushing group

- Many sizes available

- Many materials available, including Stainless Steel, Brass, Galvanized Malleable Iron, and Iron

- 150 psi rated

-

MOBILE DUST COLLECTOR, AIR SCRUBBERS & PORTABLE DUST EXTRACTORS

- Ready availability all over the US

- Diesel powered

- Trailer mounted or skid mounted

- Industry leading design

- All sizes available

- Read our Dust Collector Buying Guide

- Portable dust extractor for site work

- Onsite dust collectors and onsite dust ventilation

- Industrial portable dust collectors

-

- Modular, portable ventilating fans, available in a variety of sizes

- Electric, Pneumatic, and Hazardous Electric models available

- Set-up as a stand-alone or ducted unit.

- See attached document for CFM ratings

- NOTE - Dust Socks cannot be used on electric Black Max fans larger than 16". Using a 20 or 24" electric unit with a dust sock voids the warranty.

- DUST SOCK - Sold Separately - NOTE - see limitation above

- DUCT ADAPTER - Sold Separately

-

CAPSG1

The Clemco Power Blast Suction Blast Abrasive Blasting Gun is the #1 fastest suction blast system available, designed for efficient and portable dry abrasive blasting. This lightweight tool is perfect for small-scale jobs, touch-ups, and areas with limited air supply, using as little as 40 CFM. Setup is simple—just slide the pick-up tube into a bag of abrasive, connect compressed air, and pull the trigger.

Key Features:

- Compact and Portable: Easy to handle and maneuver in tight spaces or elevated areas.

- Efficient Air Usage: Operates between 40–120 CFM, ideal for limited air supply jobs.

- Durable Components: Includes a ¼” air jet and ½” tungsten carbide nozzle for lasting performance.

- Wide Media Compatibility: Works with most abrasive media straight from the bag.

- Complete Kit: Comes with a gun, nozzle, and pick-up tubes for convenience.

- Versatile Applications: Perfect for touch-ups, confined spaces, or small surface preparation tasks.

CAPSG1The Clemco Power Blast Suction Blast Abrasive Blasting Gun is the #1 fastest suction blast system available, designed for efficient and portable dry abrasive blasting. This lightweight tool is perfect for small-scale jobs, touch-ups, and areas with limited air supply, using as little as 40 CFM. Setup is simple—just slide the pick-up tube into a bag of abrasive, connect compressed air, and pull the trigger.

Key Features:

- Compact and Portable: Easy to handle and maneuver in tight spaces or elevated areas.

- Efficient Air Usage: Operates between 40–120 CFM, ideal for limited air supply jobs.

- Durable Components: Includes a ¼” air jet and ½” tungsten carbide nozzle for lasting performance.

- Wide Media Compatibility: Works with most abrasive media straight from the bag.

- Complete Kit: Comes with a gun, nozzle, and pick-up tubes for convenience.

- Versatile Applications: Perfect for touch-ups, confined spaces, or small surface preparation tasks.

-

CAPSG02641

How can you abrasive blast without a blast pot? With a Clemco suction gun! At a fraction of the cost of a regular blast pot setup, the Clemco SG300 suction gun offers easy portability and can blast with as little as 12 CFM at 40 PSI using the included 1/8" air jet and #5 nozzle. If more CFM / PSI are available, a different air jet / nozzle configuration could improve production speed. The Suction Blaster is intended for small projects / touch-up work, etc. It is not as fast as blasting with a regular blast pot.

CAPSG02641How can you abrasive blast without a blast pot? With a Clemco suction gun! At a fraction of the cost of a regular blast pot setup, the Clemco SG300 suction gun offers easy portability and can blast with as little as 12 CFM at 40 PSI using the included 1/8" air jet and #5 nozzle. If more CFM / PSI are available, a different air jet / nozzle configuration could improve production speed. The Suction Blaster is intended for small projects / touch-up work, etc. It is not as fast as blasting with a regular blast pot.

-

BMS1001TVFREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Manufacturer Warranty

- 10 cu ft Schmidt® Blast pot

- Excellent for a blastroom application with 1-2 blasters

- Single outlet Thompson® Valve II abrasive metering valve, Dual available

- Abrasive capacity

- Garnet 1500 lbs

- Steel Grit 2450 lbs

- Comes with pneumatic deadman handle and 55ft of control hose, Electric available

BMS1001TVFREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Manufacturer Warranty- 10 cu ft Schmidt® Blast pot

- Excellent for a blastroom application with 1-2 blasters

- Single outlet Thompson® Valve II abrasive metering valve, Dual available

- Abrasive capacity

- Garnet 1500 lbs

- Steel Grit 2450 lbs

- Comes with pneumatic deadman handle and 55ft of control hose, Electric available

-

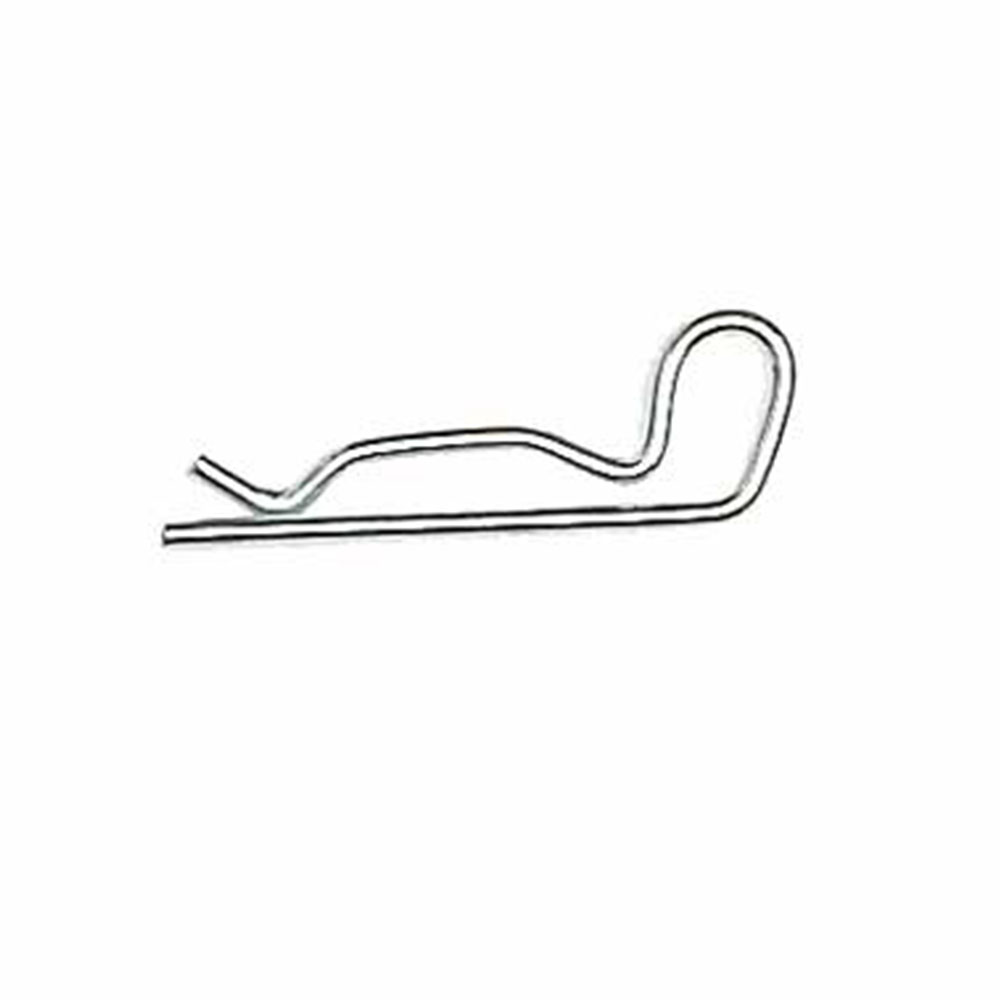

- Must be installed in all blast hose couplings for safety

- Stops the blast hose coupling rotating and disconnecting

- HF-CLP1 is the thin type lock pin (Pack of 25)

- HF-CLP2 is the thick type lock pin (Pack of 25)

- HF-CLP3 is the nylon coupling spring type lock pin (Pack of 10)

- HF-CLP4 is the multi-fit spring type lock pin (Pack of 25)

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment