Blasting, UHP & Site Equipment

Showing 16–30 of 629 results

-

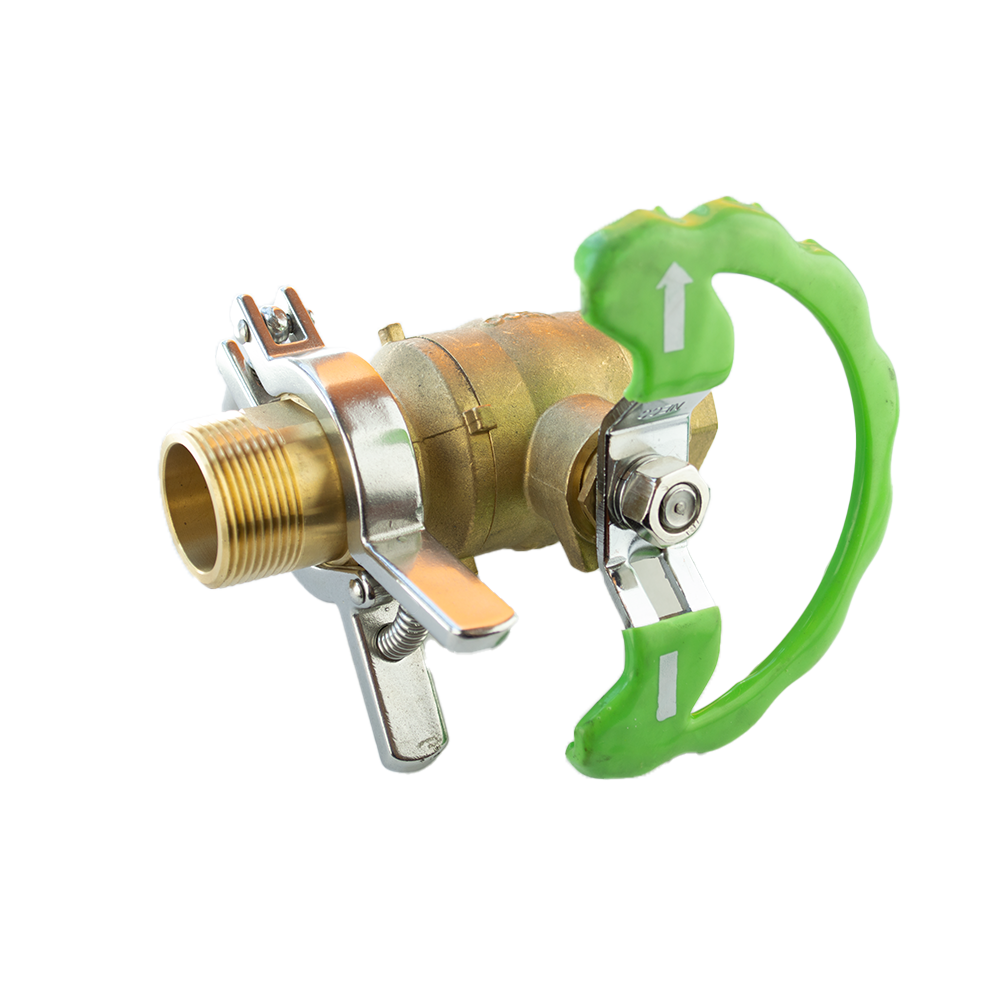

GV2410320BVThe GV2410320BV Union End Ball Valve with Tri-Clover Adapter Clamp Assembly is designed for improved serviceability of abrasive metering valves in blast pot setups. Ideal for new installations, it allows technicians to remove the valve for maintenance without needing to empty abrasive material from the pot. Ensure 9 inches of clearance before ordering.

- Provides easy metering valve removal without pot emptying

- Installs between the blast pot and abrasive metering valve

- Recommended for new installations, but can also be retrofitted to existing pots

- Adds 9 inches of height—verify clearance before ordering

- Includes: Union End Ball Valve (SKU GV2408907, MPN 2408-907)

- Includes: Tri-Clover Adapter Clamp Assembly (SKU GV2410320)

- Assembly SKU: GV2410320BV

GV2410320BVThe GV2410320BV Union End Ball Valve with Tri-Clover Adapter Clamp Assembly is designed for improved serviceability of abrasive metering valves in blast pot setups. Ideal for new installations, it allows technicians to remove the valve for maintenance without needing to empty abrasive material from the pot. Ensure 9 inches of clearance before ordering.- Provides easy metering valve removal without pot emptying

- Installs between the blast pot and abrasive metering valve

- Recommended for new installations, but can also be retrofitted to existing pots

- Adds 9 inches of height—verify clearance before ordering

- Includes: Union End Ball Valve (SKU GV2408907, MPN 2408-907)

- Includes: Tri-Clover Adapter Clamp Assembly (SKU GV2410320)

- Assembly SKU: GV2410320BV

-

The Schmidt® Bulk AmphiBlast™ is a high-capacity wet/dry blasting system (aka Dustless Mega Blaster or Dustless Bulk Pot) that features proven Schmidt controls and innovative moisture injection technology for precise air, abrasive, and water flow control. Available in multiple configurations with up to four independently controlled blast outlets, this system delivers maximum productivity, efficiency, and versatility. Key Features:

- Operate up to four nozzles simultaneously with individual mode settings

- Advanced abrasive metering technology with choice of either the Thompson II or the TeraValve

- Switch between wet blast, dry blast, Softwash™, and blowoff with ease

- Available in 45 cf, 120 cf, and 160 cf capacities

- HALOK® Closure Safety System for enhanced operator protection

- Ergo-Ladder® with anti-slip twisted rungs for safe access

- Mounting options include:

- Shipping Legs - use when mounting on existing customer equipment

- Custom Steel Skid w/forklift pockets

- Yard Trailer

- Highway Trailer

-

Western Technology 4400 Series Mounts provide secure and adaptable mounting solutions for Western Technology 4400 Series Area Lights. Designed for various job site conditions, these mounts ensure stable positioning and optimal lighting for abrasive blasting and industrial applications. Available Mounting Options:

- Scaffold Mount – Attaches securely to scaffolding for stable, elevated lighting. MPN: 4400 HD Scaff MT

- Flat Magnet Mount – Provides a strong, stationary magnetic attachment to flat surfaces. MPN: 4400 MAGNET

- Knuckle Magnet Mount – Offers flexible positioning with an adjustable joint for directional lighting. MPN: 4400 KNUCKLE

-

Western Technology's Link-A-Light power and linking cords are designed to safely power and connect 4400 Series LED string lights in ordinary location environments. Available in 10', 20', 25', and 50' lengths, these heavy-duty cords support daisy-chaining up to 250 feet and come standard with a 15 Amp plug unless specified otherwise.

- Compatible with Link-A-Light Industrial LED String Light System

- Supports daisy-chaining up to 250 feet total length

- Lengths available: 10', 20', 25' (standard), and 50'

- Standard 15 Amp plug; 20 Amp option available upon request

- Heavy-duty construction for rugged worksite use

- For ordinary location use only – not explosion-rated

- MPNs: 4410E, 4410L, 4420E, 4420L, 4425E, 4425L, 4450E, 4450L

-

RUBVDV700BlastOne's VertiDrive V700 Blasting Robot represents the cutting edge in surface preparation technology, engineered to revolutionize large-scale blasting projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for performance, efficiency, and safety. RENT or PURCHASE this surface preparation work-horse! The next-generation V700 VertiDrive. Boosting performance and profits on large blasting projects. Purchase pricing is typically between $125,000 and $204,000, depending on configuration. BlastOne can provide on-site training and ongoing support to ensure maximum productivity from Day 1. Schedule a call with our SMEs to calculate and expected ROI for your next project.

- Faster Production. Now holds up to 3 nozzles and each nozzle is up to 30% faster than the best hand blasting. Highest productivity of any robotic blasting system!

- Cleaner Surface. Provides consistent blasting quality by adjustment of equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and now even upside-down!

- Versatile. The V700 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Ultra High Pressure (UHP) coating removal.

- Power Wash surface cleaning.

- Reduced Cost-of-Ownership. The VertiDrive V700 has the lowest maintenance cost of any blasting robot.

- Looking for more information? Click here to read more…

RUBVDV700BlastOne's VertiDrive V700 Blasting Robot represents the cutting edge in surface preparation technology, engineered to revolutionize large-scale blasting projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for performance, efficiency, and safety. RENT or PURCHASE this surface preparation work-horse! The next-generation V700 VertiDrive. Boosting performance and profits on large blasting projects. Purchase pricing is typically between $125,000 and $204,000, depending on configuration. BlastOne can provide on-site training and ongoing support to ensure maximum productivity from Day 1. Schedule a call with our SMEs to calculate and expected ROI for your next project.- Faster Production. Now holds up to 3 nozzles and each nozzle is up to 30% faster than the best hand blasting. Highest productivity of any robotic blasting system!

- Cleaner Surface. Provides consistent blasting quality by adjustment of equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and now even upside-down!

- Versatile. The V700 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Ultra High Pressure (UHP) coating removal.

- Power Wash surface cleaning.

- Reduced Cost-of-Ownership. The VertiDrive V700 has the lowest maintenance cost of any blasting robot.

- Looking for more information? Click here to read more…

-

BlastOne's MistBlaster® Wet/Dry Blast Machine is a versatile solution designed to meet the diverse needs of professionals in the blasting industry. This innovative machine, exclusively developed by BlastOne, offers exceptional flexibility with both combo skid and portable configurations, ensuring reliable performance in various project settings. Features:

- Dual-mode blasting: seamless transition between wet and dry blasting.

- Combo skid options: integrate breathing air packages, air dryers, and more…

- … or Portable configuration: with wheels for easy transport and setup.

- Ultra-low water use: just 1 pint/minute in MistBlast mode.

- Enhanced control panel: 4 operational modes (Dry Blast, Wet Blast, Wash Down, Blow Down).

- Reliable TeraValve® abrasive metering system for consistent performance and pressure-hold technology.

- Compatible with most abrasives in dry mode; garnet or crushed glass recommended for wet mode.

- High-flow connections maintain optimal nozzle performance with very low pressure drop.

- 12v Electric Controls for the fastest and safest deadman action

-

BlastOne's 160 CF Mega MistBlaster is the ultimate solution for professionals seeking flexibility in surface preparation. This advanced blast machine, exclusively designed by BlastOne, offers both wet and dry blasting capabilities, making it ideal for large projects where efficiency and versatility are paramount.

- Versatility. 4 functions available at the flip of a switch:

- MistBlasting / Wet (slurry) Blasting

- Traditional Dry Blasting

- Wash-down mode

- Blow-off mode

- Each outlet is independently controlled, giving even greater versatility.

- Capability. With its 4 outlets, this workhorse can power up to 4 operators OR a VertiDrive robotic blaster and manual blasting simultaneously.

- Huge capacity - As typically configured with 160 cubic feet (aka 8 Ton), this bulk pot holds half a truckload of garnet.

- Mount Options as follows:

- Highway Trailer

- Skid Mount

- Shipping Legs (for mounting on your own equipment)

- Available Cost Saving Option - We can convert your existing Schmidt® Dry bulk pot with to our Mega MistBlaster with our retrofit package. Available as a Limited version (without metering / air valves, for new pots) or as a Full version (with all valves, for used pots).

- Versatility. 4 functions available at the flip of a switch:

-

MB60160Boost profits and reduce frustration by converting your EcoQuip® blasting rig to MistBlaster® technology.

- Boost profits by:

- Increased production speed

- Reduced wasted abrasive and rust inhibitor

- Less water usage, reduced cleanup time

- Winning more projects because dry blasting is easy too!

- Reduce frustrations by:

- No need to drain the tank at end of day

- Allows adjustment of water / abrasive ratio

MB60160Boost profits and reduce frustration by converting your EcoQuip® blasting rig to MistBlaster® technology.- Boost profits by:

- Increased production speed

- Reduced wasted abrasive and rust inhibitor

- Less water usage, reduced cleanup time

- Winning more projects because dry blasting is easy too!

- Reduce frustrations by:

- No need to drain the tank at end of day

- Allows adjustment of water / abrasive ratio

- Boost profits by:

-

VaVacuload1P

AVAILABLE FOR RENTAL OR PURCHASE

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- Will vacuum upto 2 ton/hour

- Requires 350 cfm compressed air at 120 psi

- Generates 700 cfm vacuum

- 1 Dust Collector Cartridge with filtration area of 229 sq ft.

- Automatic Reverse Pulse Cleaning

- Use with 3" vacuum hose

VaVacuload1PAVAILABLE FOR RENTAL OR PURCHASE

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- Will vacuum upto 2 ton/hour

- Requires 350 cfm compressed air at 120 psi

- Generates 700 cfm vacuum

- 1 Dust Collector Cartridge with filtration area of 229 sq ft.

- Automatic Reverse Pulse Cleaning

- Use with 3" vacuum hose

-

-

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

-

The Schmidt® AmphiBlast™ is a versatile, dual-purpose abrasive blasting system designed for efficient wet and dry blasting. Featuring a patent-pending water injection system and Schmidt® Thompson® Valve II, it offers precise control of air, abrasive, and water flows for maximum productivity and minimal material waste. Available in single and dual outlet configurations, all with fork-pocket skid mounts. Key Features:

- Switch between wet blast, dry blast, Softwash™, and blowoff effortlessly.

- Precise water injection for optimal blasting performance and minimal water use

- Supports a wide range of abrasives (coarse and fine)

- High and low-pressure blasting capabilities

- Set and Forget mode switching for consistent performance

- Improved lid construction and quieter blowdown system

- Size Options:

- 1-Outlet, 4.5 cu. ft. Blast Pot | 80-Gallon Water Tank

- 2-Outlet, 6.5 cu. ft. Blast Pot | 165-Gallon Water Tank

- Controls Choices:

- Pneumatic w/Compact BAABS G3 Trigger Deadman

- 12v Electric w/Compact BAABS G3 Trigger Deadman

- Abrasive Cut-Off (ACO) available on 2-outlet 12v Electric

- (The BAABS is the innovative ergonomic system by Schmidt that pairs perfectly with the G3 deadman)

-

The Clemco Wetblast FLEX™ System is a versatile wet and dry blasting solution, designed for maximum flexibility and productivity. Whether you're blasting in dust-sensitive urban areas or open environments requiring dry blasting, the FLEX system adapts to any job, helping you stay compliant, efficient, and profitable. Key Features:

- Switch between wet and dry blasting with ease

- High-performance water injection system for optimal dust suppression

- Precise water adjustment controls for customizable blasting

- 120-gallon water storage tank with pump included for flexible water sourcing

- Easy-to-use controls for quick setup and operation

- Available in Base Unit and Flex Package configurations

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment