Blasting, UHP & Site Equipment

Showing 271–285 of 607 results

-

ACS400AC

Replacement radiator for ACS400SQUAT BlastOne Air Dryer.

- Efficient cooling with 400 CFM capacity

- Pneumatic Fan for rapid heat dissipation

- Durable construction for long-term reliability

- Compatible with various pneumatic tools

- 2" fitting

NOTE: This is not a stand-alone air dryer - it is the radiator used in the 400 CFM Squat dryer, and is offered here as a replacement radiator for that unit only.

ACS400ACReplacement radiator for ACS400SQUAT BlastOne Air Dryer.

- Efficient cooling with 400 CFM capacity

- Pneumatic Fan for rapid heat dissipation

- Durable construction for long-term reliability

- Compatible with various pneumatic tools

- 2" fitting

NOTE: This is not a stand-alone air dryer - it is the radiator used in the 400 CFM Squat dryer, and is offered here as a replacement radiator for that unit only.

-

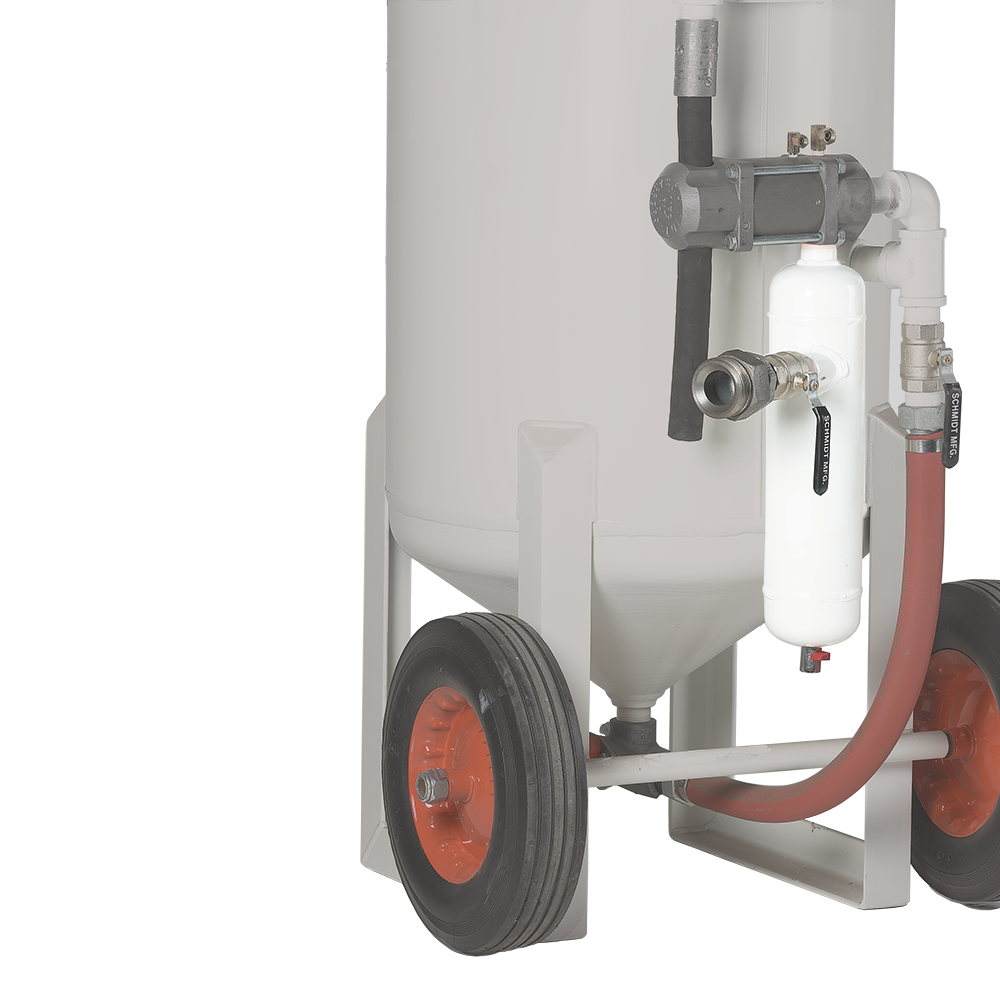

Built by Schmidt®, these moisture separators are available in multiple versions as follows:

- Size

- 800 or 1600 CFM capacity

- Configuration

- Stationary or Portable (with handle, axle & wheels)

- Fittings

- Built with 2" NPT ports on both Inlet and Outlet, these can be equipped with your choice of Spud or 4-claw fittings, ball valves, splitters, etc.

- Size

-

The Inlet Airline Moisture Separator, designed specifically for abrasive blasting, provides final stage moisture droplet removal before air enters the blast machine, ensuring minimal pressure loss for peak blasting productivity. Utilizing an elementless design with a tangential flow, and an internal stainless steel coalescer, it handles large air volumes without efficiency loss. This system can be sized at 250cfm or 400cfm based on your blast nozzle and compressor size, and though it requires separate order of inlet fitting or ball valve, it promises improved blasting performance with drier air.

- Installed at blast machine inlet for final stage moisture droplet removal before air enters blast machine

- Tangential flow and elementless design

- Minimal pressure loss for peak blasting productivity

- Requires 1/4' ball valve for drainage - part no. FVBL006

- Optional autodrain accessory available

- Male threaded inlet and outlet ports

- Inlet fitting or ball valve not supplied - order separately

- Specify Size - 250cfm or 400cfm, based on the size of your blast nozzle and compressor

- Includes internal stainless steel coalescer

-

ACSDR50

- Suits the AirPrep ADS Series

- Replacement deliquescent tablets to refill an air dryer.

- Also referred to as desiccant tablets

- Hard, white tablets can absorb up to 4 times their own weight in water!

- Comes in 50 lb bags, 40 bags per pallet

ACSDR50- Suits the AirPrep ADS Series

- Replacement deliquescent tablets to refill an air dryer.

- Also referred to as desiccant tablets

- Hard, white tablets can absorb up to 4 times their own weight in water!

- Comes in 50 lb bags, 40 bags per pallet

-

DMECKCLIP

- Heavy-Duty Battery Charging Clamps - Bare

- Insulated Vinyl handles for your safety

- 80 Amp capacity, suits 12/24V DC batteries

- 14 to 18 AWG

- Sold as a pair - Black/Red

DMECKCLIP- Heavy-Duty Battery Charging Clamps - Bare

- Insulated Vinyl handles for your safety

- 80 Amp capacity, suits 12/24V DC batteries

- 14 to 18 AWG

- Sold as a pair - Black/Red

-

LRFSVAT2000

- Suited for the VacuLoad 1 - Skid Mounted Vacuum System

- Acts as a control valve to automatically manage frequency of dust cartridge pulses

- Helps extend life of dust collection cartridge

- Sold individually

LRFSVAT2000- Suited for the VacuLoad 1 - Skid Mounted Vacuum System

- Acts as a control valve to automatically manage frequency of dust cartridge pulses

- Helps extend life of dust collection cartridge

- Sold individually

-

DMWTX1002KLBALL AND CHAIN SOLD SEPARATELY

- Increases productivity and reduces costs

- Permanently sealed pneumatic switch is protected by abrasion-resistant urethane

DMWTX1002KLBALL AND CHAIN SOLD SEPARATELY- Increases productivity and reduces costs

- Permanently sealed pneumatic switch is protected by abrasion-resistant urethane

-

DM227000015PKWhen your BAABS Deadman system needs refreshed, we have the replacement parts you need. This is a pack of 4 of the thread forming screws used in the handle. Other individual components are also available. See the Repair Parts tab on the main BAABS page here.DM227000015PKWhen your BAABS Deadman system needs refreshed, we have the replacement parts you need. This is a pack of 4 of the thread forming screws used in the handle. Other individual components are also available. See the Repair Parts tab on the main BAABS page here.

-

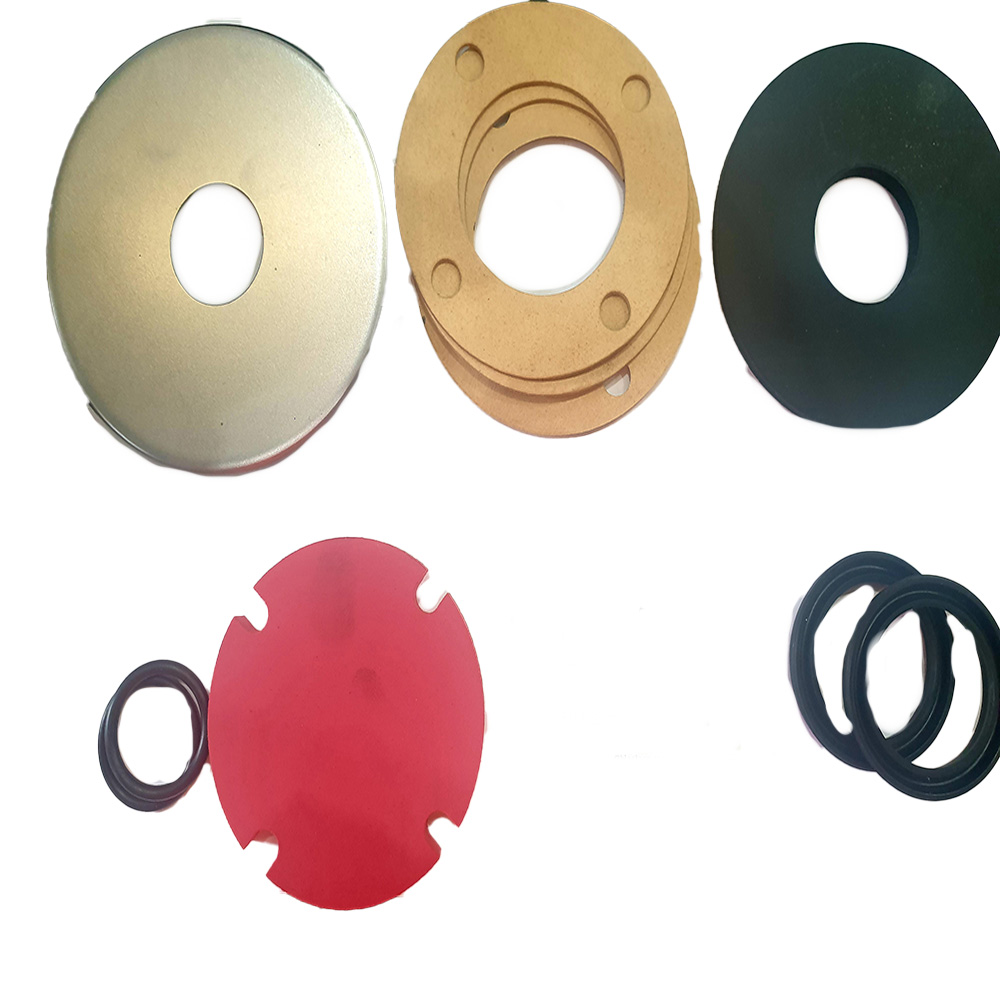

DMRMS1001Service repair kit includes seals, gaskets, etc. to service both the inlet and the exhaust valveDMRMS1001Service repair kit includes seals, gaskets, etc. to service both the inlet and the exhaust valve

-

BA01989BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement bottom cap seal for the inlet valve (factory part number 01989).BA01989BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement bottom cap seal for the inlet valve (factory part number 01989).

-

DMRMCATCSBlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement screen for 1" abrasive trap (factory part number 02012) and it is also included in the applicable service kit available here.DMRMCATCSBlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement screen for 1" abrasive trap (factory part number 02012) and it is also included in the applicable service kit available here.

-

DMRMS1002

- Optional service repair kit also includes exhaust deflector plate and gasket

DMRMS1002- Optional service repair kit also includes exhaust deflector plate and gasket

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment