Blasting, UHP & Site Equipment

Welcome to our Blasting & UHP Site Equipment category, where you’ll find a wide range of high-performance equipment designed for industrial sandblasting and ultra-high-pressure (UHP) water blasting applications. Whether you’re preparing surfaces for coatings, removing tough contaminants, or performing large-scale industrial cleaning, our equipment ensures precision and durability. From blasting pots and hoses to UHP water jetting systems, we provide reliable tools built to withstand the toughest environments. Explore our collection to find the right equipment for your project, and let us help you achieve exceptional results with every blast.

Showing 1–15 of 617 results

-

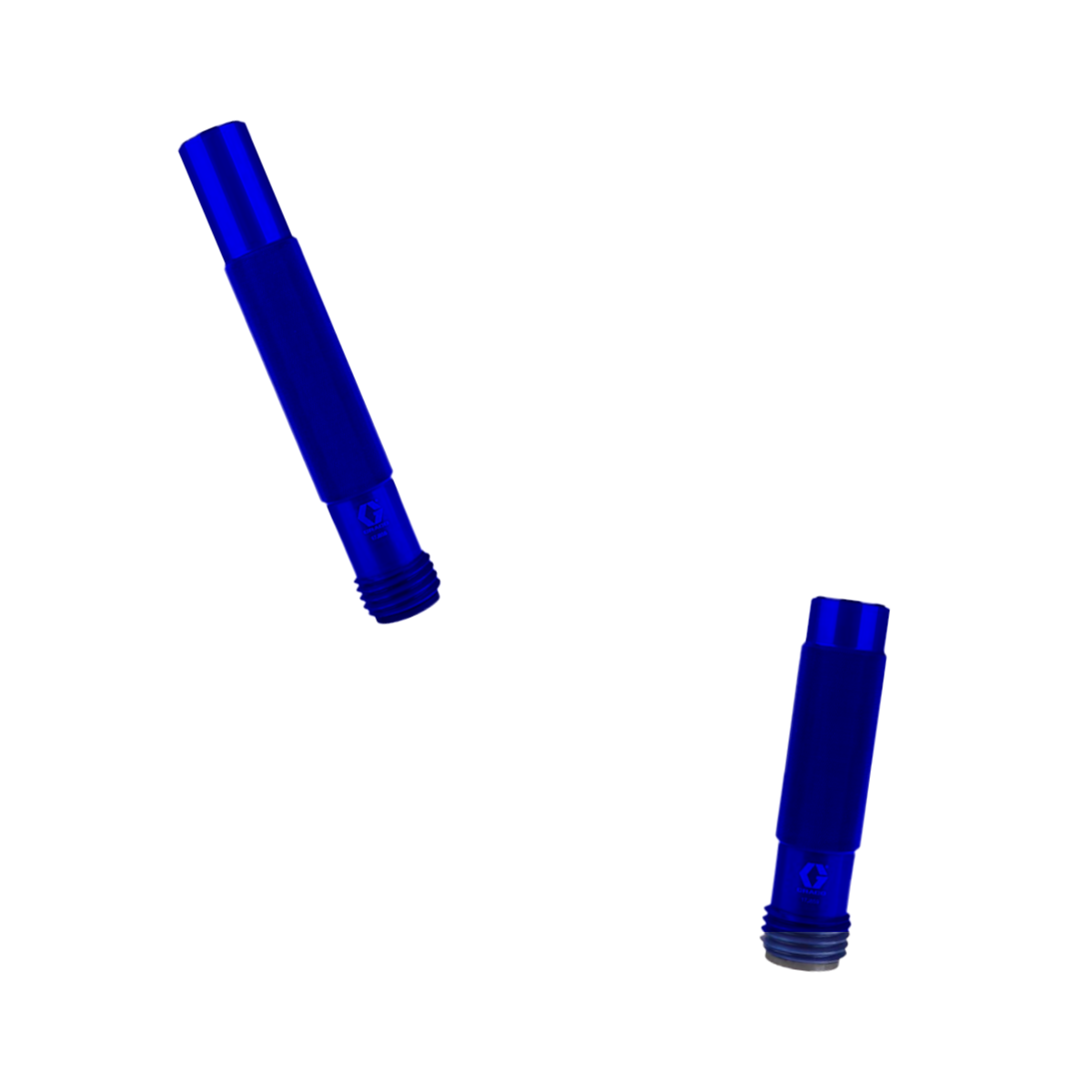

INBNATMaintain optimal blasting efficiency with our Abrasive Blasting Nozzle Wear Gauge Set, designed for quick and accurate assessment of nozzle wear in sizes #6, #7, #8, and #10. Featuring an extended design, this tool allows for measurements without removing the nozzle from its holder and eliminates the need for additional instruments like pencils. Regular use helps detect wear as small as 1/32", ensuring timely nozzle replacements to maintain peak performance.

- Measures nozzle sizes: #6, #7, #8, and #10

- Detects wear starting at 1/32"

- Extended length enables in-place measurements without nozzle removal. Simply drop in the applicable gauge into the end of the nozzle and if it goes through, it's time to replace!

- No additional tools required for operation

- Enhances blasting efficiency by identifying worn nozzles promptly

- Durable construction for long-term use

INBNATMaintain optimal blasting efficiency with our Abrasive Blasting Nozzle Wear Gauge Set, designed for quick and accurate assessment of nozzle wear in sizes #6, #7, #8, and #10. Featuring an extended design, this tool allows for measurements without removing the nozzle from its holder and eliminates the need for additional instruments like pencils. Regular use helps detect wear as small as 1/32", ensuring timely nozzle replacements to maintain peak performance.- Measures nozzle sizes: #6, #7, #8, and #10

- Detects wear starting at 1/32"

- Extended length enables in-place measurements without nozzle removal. Simply drop in the applicable gauge into the end of the nozzle and if it goes through, it's time to replace!

- No additional tools required for operation

- Enhances blasting efficiency by identifying worn nozzles promptly

- Durable construction for long-term use

-

GRACO® SPECIAL PURCHASE - NOZZLE FINAL CLEARANCE! These nozzles, originally produced for the Graco EcoQuip series, are top quality, new condition and suitable for any blasting equipment - wet or dry. At 90% off MSRP, these nozzles on final clearance pricing are the cheapest blast nozzles currently on the market, and include the following types:

- General Purpose (contractor thread)

- Hyper Extended Venturi Hi-Performance (contractor thread)

- SST stainless steel jacket (medium thread)

- Double Venturi (contractor thread)

-

Abrasive Blast Pots from Schmidt offer versatile, high-performance solutions for abrasive blasting across contractor, industrial, and blast room applications. Whether you need a highly portable unit for field applications where manuverability is key, or a larger machine for high volume blast rooms, the entire range of sizes from 0.9 to 20CF are all built with the same industrial grade made-in-USA workmanship. Key Features:

- Available Sizes: 0.9, 1.5, 3.5, 6.5, 10, and 20 cu. ft.

- Operation Options:

- Pressure-release ‘blows down’ automatically upon release of the deadman trigger. It costs less up front versus pressure-hold.

- Pressure-hold maintains the pressure in the blast pot even after releasing the deadman trigger. Less abrasive is wasted when the trigger is activated and although it costs more up-front than pressure-release, it can save 15% on abrasive consumption - especially in projects with a lot of on-off deadman activation. Pressure is manually relieved via a ball valve when the pot needs refilled with abrasive.

- Abrasive Metering Valves – Thompson® Valve II, MicroValve 3®, and TeraValve XL®

- Control Options - Standard Pneumatic, or upgrade to Electric for zero freeze-up issues in cold weather and fastest action - especially when the control line exceeds 100 feet. Response® deadman handles available in either the G2 Paddle-type or the innovative BAABS G3 Trigger-type.

- Other options: Long list of available customizable features for any blasting environment including Lids and/or Screens, Stationary or Portable configuration, VBS II™ blowdown suppression for safer, quieter operation and even a hybrid design incorporating an aftercooling dryer with the pot.

-

The Schmidt® Bulk AmphiBlast™ is a high-capacity wet/dry blasting system (aka Dustless Mega Blaster or Dustless Bulk Pot) that features proven Schmidt controls and innovative moisture injection technology for precise air, abrasive, and water flow control. Available in multiple configurations with up to four independently controlled blast outlets, this system delivers maximum productivity, efficiency, and versatility. Key Features:

- Operate up to four nozzles simultaneously with individual mode settings

- Advanced abrasive metering technology with choice of either the Thompson II or the TeraValve

- Switch between wet blast, dry blast, Softwash™, and blowoff with ease

- Available in 45 cf, 120 cf, and 160 cf capacities

- HALOK® Closure Safety System for enhanced operator protection

- Ergo-Ladder® with anti-slip twisted rungs for safe access

- Mounting options include:

- Shipping Legs - use when mounting on existing customer equipment

- Custom Steel Skid w/forklift pockets

- Yard Trailer

- Highway Trailer

-

Western Technology 4400 Series Mounts provide secure and adaptable mounting solutions for Western Technology 4400 Series Area Lights. Designed for various job site conditions, these mounts ensure stable positioning and optimal lighting for abrasive blasting and industrial applications. Available Mounting Options:

- Scaffold Mount – Attaches securely to scaffolding for stable, elevated lighting. MPN: 4400 HD Scaff MT

- Flat Magnet Mount – Provides a strong, stationary magnetic attachment to flat surfaces. MPN: 4400 MAGNET

- Knuckle Magnet Mount – Offers flexible positioning with an adjustable joint for directional lighting. MPN: 4400 KNUCKLE

-

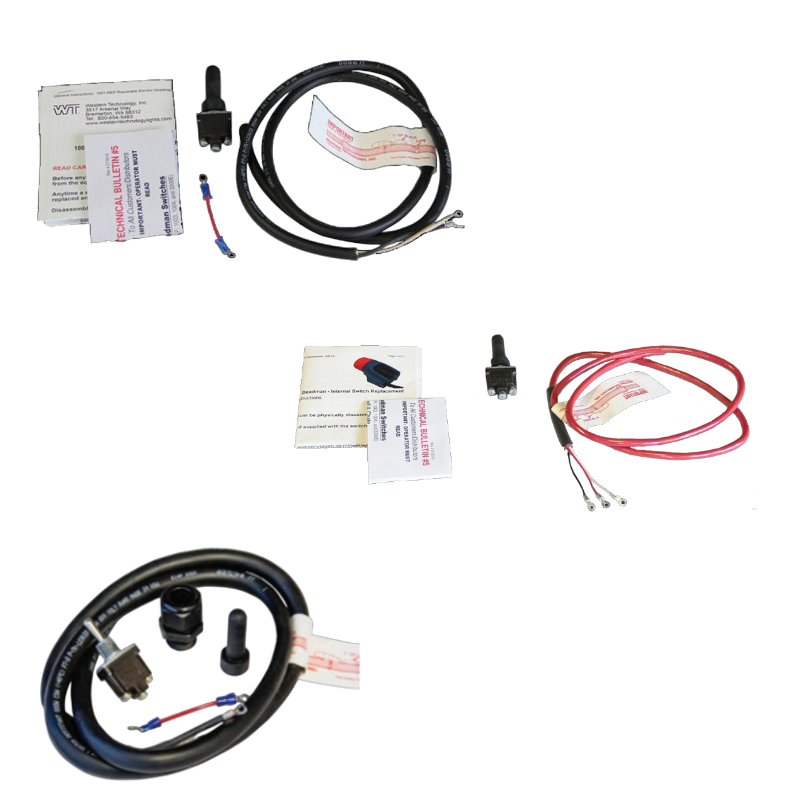

Western Technology Deadman (aka ball and chain, or RedHead™) Repair Kits provide genuine replacement components for restoring function to your SURE-FIRE electric remote control deadman handles and Wrist-EZ deadman switches. These service kits are essential for maintaining reliable and safe operation of abrasive blasting systems. Available Options:

- MPN: 1001-KIT. Repair kit for 2-wire RedHead™ deadman

- MPN: 1001-KIT-3EC. Repair Kit for 3-wire RedHead™ deadman

- MPN: 1004-KIT. Repair Kit for 2-wire Wrist-EZ deadman

- MPN: 1004-KIT-3. Repair Kit for 3-wire Wrist-EZ deadman

-

Western Technology's Link-A-Light power and linking cords are designed to safely power and connect 4400 Series LED string lights in ordinary location environments. Available in 10', 20', 25', and 50' lengths, these heavy-duty cords support daisy-chaining up to 250 feet and come standard with a 15 Amp plug unless specified otherwise.

- Compatible with Link-A-Light Industrial LED String Light System

- Supports daisy-chaining up to 250 feet total length

- Lengths available: 10', 20', 25' (standard), and 50'

- Standard 15 Amp plug; 20 Amp option available upon request

- Heavy-duty construction for rugged worksite use

- For ordinary location use only – not explosion-rated

- MPNs: 4410E, 4410L, 4420E, 4420L, 4425E, 4425L, 4450E, 4450L

-

BlastOne's MistBlaster® Wet/Dry Blast Machine is a versatile solution designed to meet the diverse needs of professionals in the blasting industry. This innovative machine, exclusively developed by BlastOne, offers exceptional flexibility with both combo skid and portable configurations, ensuring reliable performance in various project settings.

Features:

- Dual-mode blasting: seamless transition between wet and dry blasting.

- Combo skid options: integrate breathing air packages, air dryers, and more…

- … or Portable configuration: with wheels for easy transport and setup.

- Ultra-low water use: just 1 pint/minute in MistBlast mode.

- Enhanced control panel: 4 operational modes (Dry Blast, Wet Blast, Wash Down, Blow Down).

- Reliable TeraValve® abrasive metering system for consistent performance and pressure-hold technology.

- Compatible with most abrasives in dry mode; garnet or crushed glass recommended for wet mode.

- High-flow connections maintain optimal nozzle performance with very low pressure drop.

- 12v Electric Controls for the fastest and safest deadman action

-

BlastOne's 160 CF Mega MistBlaster is the ultimate solution for professionals seeking flexibility in surface preparation. This advanced blast machine, exclusively designed by BlastOne, offers both wet and dry blasting capabilities, making it ideal for large projects where efficiency and versatility are paramount.

- Versatility. 4 functions available at the flip of a switch:

- MistBlasting / Wet (slurry) Blasting

- Traditional Dry Blasting

- Wash-down mode

- Blow-off mode

- Each outlet is independently controlled, giving even greater versatility.

- Capability. With its 4 outlets, this workhorse can power up to 4 operators OR a VertiDrive robotic blaster and manual blasting simultaneously.

- Huge capacity - As typically configured with 160 cubic feet (aka 8 Ton), this bulk pot holds half a truckload of garnet.

- Mount Options as follows:

- Highway Trailer

- Skid Mount

- Shipping Legs (for mounting on your own equipment)

- Available Cost Saving Option - We can convert your existing Schmidt® Dry bulk pot with to our Mega MistBlaster with our retrofit package. Available as a Limited version (without metering / air valves, for new pots) or as a Full version (with all valves, for used pots).

- Versatility. 4 functions available at the flip of a switch:

-

MB60160Boost profits and reduce frustration by converting your EcoQuip® blasting rig to MistBlaster® technology.

- Boost profits by:

- Increased production speed

- Reduced wasted abrasive and rust inhibitor

- Less water usage, reduced cleanup time

- Winning more projects because dry blasting is easy too!

- Reduce frustrations by:

- No need to drain the tank at end of day

- Allows adjustment of water / abrasive ratio

MB60160Boost profits and reduce frustration by converting your EcoQuip® blasting rig to MistBlaster® technology.- Boost profits by:

- Increased production speed

- Reduced wasted abrasive and rust inhibitor

- Less water usage, reduced cleanup time

- Winning more projects because dry blasting is easy too!

- Reduce frustrations by:

- No need to drain the tank at end of day

- Allows adjustment of water / abrasive ratio

- Boost profits by:

-

The Schmidt® AmphiBlast™ is a versatile, dual-purpose abrasive blasting system designed for efficient wet and dry blasting. Featuring a patent-pending water injection system and Schmidt® Thompson® Valve II, it offers precise control of air, abrasive, and water flows for maximum productivity and minimal material waste. Available in single and dual outlet configurations, all with fork-pocket skid mounts. Key Features:

- Switch between wet blast, dry blast, Softwash™, and blowoff effortlessly.

- Precise water injection for optimal blasting performance and minimal water use

- Supports a wide range of abrasives (coarse and fine)

- High and low-pressure blasting capabilities

- Set and Forget mode switching for consistent performance

- Improved lid construction and quieter blowdown system

Available Configurations:

- Size Options:

- 1-Outlet, 4.5 cu. ft. Blast Pot | 80-Gallon Water Tank

- 2-Outlet, 6.5 cu. ft. Blast Pot | 165-Gallon Water Tank

- Controls Choices:

- Pneumatic w/Compact BAABS G3 Trigger Deadman

- 12v Electric w/Compact BAABS G3 Trigger Deadman

- Abrasive Cut-Off (ACO) available on 2-outlet 12v Electric

- (The BAABS is the innovative ergonomic system by Schmidt that pairs perfectly with the G3 deadman)

-

The Clemco Wetblast FLEX™ System is a versatile wet and dry blasting solution, designed for maximum flexibility and productivity. Whether you're blasting in dust-sensitive urban areas or open environments requiring dry blasting, the FLEX system adapts to any job, helping you stay compliant, efficient, and profitable. Key Features:

- Switch between wet and dry blasting with ease

- High-performance water injection system for optimal dust suppression

- Precise water adjustment controls for customizable blasting

- 120-gallon water storage tank with pump included for flexible water sourcing

- Easy-to-use controls for quick setup and operation

- Available in Base Unit and Flex Package configurations

-

DMRLX10573The Clemco RLX Pneumatic & Electric Control Handle (MPN: 10573) is a genuine OEM replacement handle designed for Clemco RLX Pneumatic and Electric Remote Control Handles. Built for durability and precise control, this replacement handle ensures safe and efficient operation of Clemco blasting equipment. Key Features:

- OEM replacement handle for Clemco RLX Pneumatic & Electric Remote Control Handles

- Restores full functionality to worn or damaged handles

- Durable construction for long-lasting performance in demanding environments

- Ensures precise control and operator safety

- Easy to install for quick maintenance and minimal downtime

DMRLX10573The Clemco RLX Pneumatic & Electric Control Handle (MPN: 10573) is a genuine OEM replacement handle designed for Clemco RLX Pneumatic and Electric Remote Control Handles. Built for durability and precise control, this replacement handle ensures safe and efficient operation of Clemco blasting equipment. Key Features:- OEM replacement handle for Clemco RLX Pneumatic & Electric Remote Control Handles

- Restores full functionality to worn or damaged handles

- Durable construction for long-lasting performance in demanding environments

- Ensures precise control and operator safety

- Easy to install for quick maintenance and minimal downtime

-

DMRLX10562The Clemco Replacement RLX Pneumatic Adaptor (MPN: 10562) is a genuine OEM replacement part designed for use with the RLX Pneumatic Remote Control Handle. This adaptor ensures secure air connections and consistent remote operation, maintaining safety and efficiency in abrasive blasting applications. Key Features:

- OEM replacement pneumatic adaptor for Clemco RLX Pneumatic Remote Control Handles

- Ensures secure air connections for reliable remote blasting control

- Durable construction for long-lasting performance in harsh environments

- Maintains proper airflow to support smooth operation

- Easy to install for quick maintenance and minimal downtime

DMRLX10562The Clemco Replacement RLX Pneumatic Adaptor (MPN: 10562) is a genuine OEM replacement part designed for use with the RLX Pneumatic Remote Control Handle. This adaptor ensures secure air connections and consistent remote operation, maintaining safety and efficiency in abrasive blasting applications. Key Features:- OEM replacement pneumatic adaptor for Clemco RLX Pneumatic Remote Control Handles

- Ensures secure air connections for reliable remote blasting control

- Durable construction for long-lasting performance in harsh environments

- Maintains proper airflow to support smooth operation

- Easy to install for quick maintenance and minimal downtime

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment