MistBlaster Wet / Dry Pots

Our MistBlaster wet and dry pots are engineered to deliver superior performance and adaptability in demanding environments. With features like dual control systems, precise water injection, and high-flow piping, these machines maximize efficiency and reduce downtime. The Mega MistBlaster and AmphiBlast™ systems support multiple operators and robotic blasters, enhancing versatility.

For tailored advice or if you need a demo, contact BlastOne or use the live chat feature in the bottom right of your browser window. Ensure your projects run smoothly with our innovative and high-capacity wet and dry blasting solutions.

Showing all 10 results

-

The Schmidt® Bulk AmphiBlast™ is a high-capacity wet/dry blasting system (aka Dustless Mega Blaster or Dustless Bulk Pot) that features proven Schmidt controls and innovative moisture injection technology for precise air, abrasive, and water flow control. Available in multiple configurations with up to four independently controlled blast outlets, this system delivers maximum productivity, efficiency, and versatility. Key Features:

- Operate up to four nozzles simultaneously with individual mode settings

- Advanced abrasive metering technology with choice of either the Thompson II or the TeraValve

- Switch between wet blast, dry blast, Softwash™, and blowoff with ease

- Available in 45 cf, 120 cf, and 160 cf capacities

- HALOK® Closure Safety System for enhanced operator protection

- Ergo-Ladder® with anti-slip twisted rungs for safe access

- Mounting options include:

- Shipping Legs - use when mounting on existing customer equipment

- Custom Steel Skid w/forklift pockets

- Yard Trailer

- Highway Trailer

-

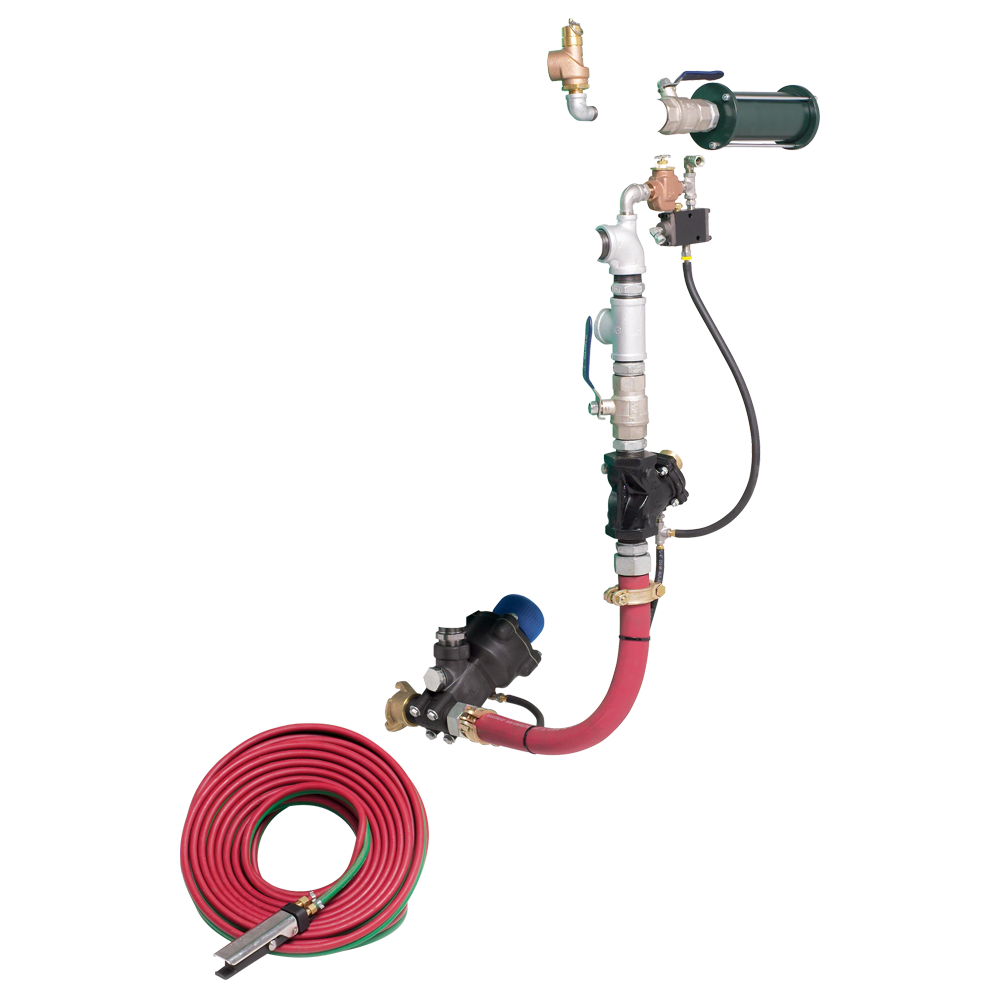

BlastOne's MistBlaster® Wet/Dry Blast Machine is a versatile solution designed to meet the diverse needs of professionals in the blasting industry. This innovative machine, exclusively developed by BlastOne, offers exceptional flexibility with both combo skid and portable configurations, ensuring reliable performance in various project settings. Features:

- Dual-mode blasting: seamless transition between wet and dry blasting.

- Combo skid options: integrate breathing air packages, air dryers, and more…

- … or Portable configuration: with wheels for easy transport and setup.

- Ultra-low water use: just 1 pint/minute in MistBlast mode.

- Enhanced control panel: 4 operational modes (Dry Blast, Wet Blast, Wash Down, Blow Down).

- Reliable TeraValve® abrasive metering system for consistent performance and pressure-hold technology.

- Compatible with most abrasives in dry mode; garnet or crushed glass recommended for wet mode.

- High-flow connections maintain optimal nozzle performance with very low pressure drop.

- 12v Electric Controls for the fastest and safest deadman action

-

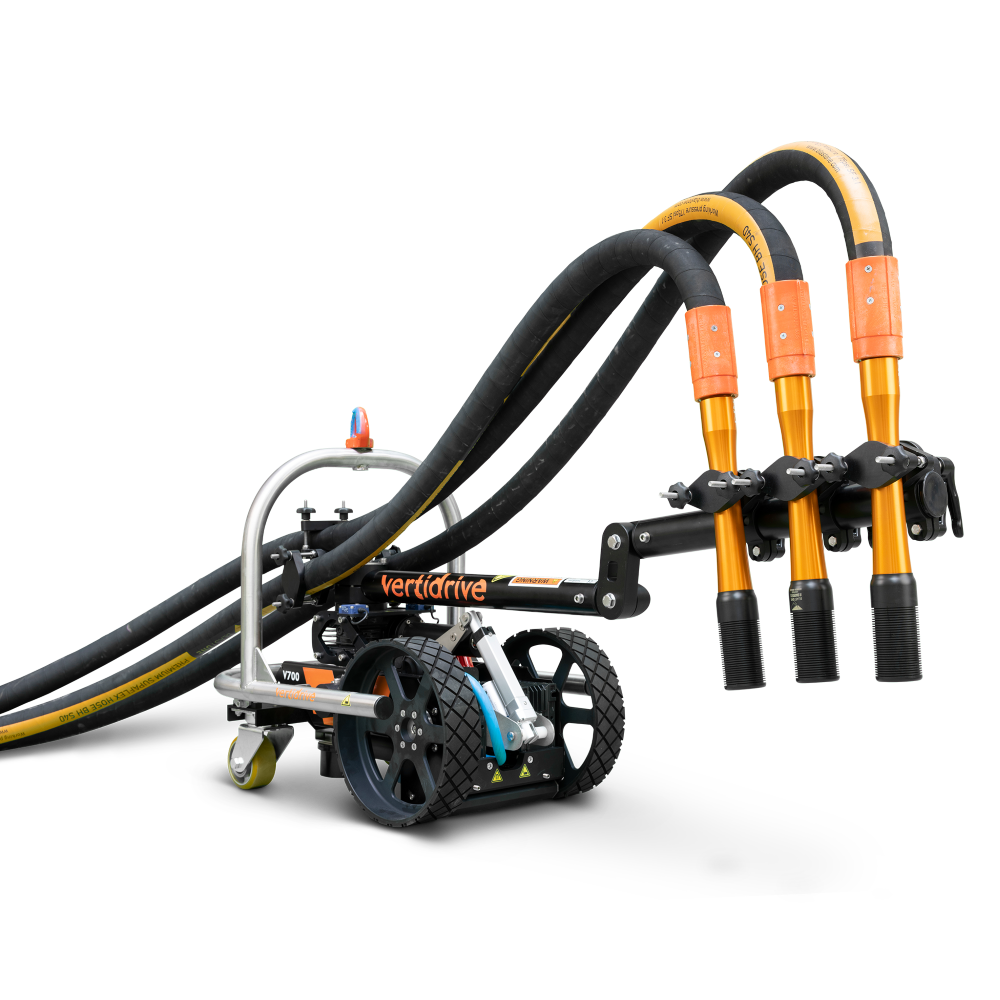

BlastOne's 160 CF Mega MistBlaster is the ultimate solution for professionals seeking flexibility in surface preparation. This advanced blast machine, exclusively designed by BlastOne, offers both wet and dry blasting capabilities, making it ideal for large projects where efficiency and versatility are paramount.

- Versatility. 4 functions available at the flip of a switch:

- MistBlasting / Wet (slurry) Blasting

- Traditional Dry Blasting

- Wash-down mode

- Blow-off mode

- Each outlet is independently controlled, giving even greater versatility.

- Capability. With its 4 outlets, this workhorse can power up to 4 operators OR a VertiDrive robotic blaster and manual blasting simultaneously.

- Huge capacity - As typically configured with 160 cubic feet (aka 8 Ton), this bulk pot holds half a truckload of garnet.

- Mount Options as follows:

- Highway Trailer

- Skid Mount

- Shipping Legs (for mounting on your own equipment)

- Available Cost Saving Option - We can convert your existing Schmidt® Dry bulk pot with to our Mega MistBlaster with our retrofit package. Available as a Limited version (without metering / air valves, for new pots) or as a Full version (with all valves, for used pots).

- Versatility. 4 functions available at the flip of a switch:

-

MB60160Boost profits and reduce frustration by converting your EcoQuip® blasting rig to MistBlaster® technology.

- Boost profits by:

- Increased production speed

- Reduced wasted abrasive and rust inhibitor

- Less water usage, reduced cleanup time

- Winning more projects because dry blasting is easy too!

- Reduce frustrations by:

- No need to drain the tank at end of day

- Allows adjustment of water / abrasive ratio

MB60160Boost profits and reduce frustration by converting your EcoQuip® blasting rig to MistBlaster® technology.- Boost profits by:

- Increased production speed

- Reduced wasted abrasive and rust inhibitor

- Less water usage, reduced cleanup time

- Winning more projects because dry blasting is easy too!

- Reduce frustrations by:

- No need to drain the tank at end of day

- Allows adjustment of water / abrasive ratio

- Boost profits by:

-

The Schmidt® AmphiBlast™ is a versatile, dual-purpose abrasive blasting system designed for efficient wet and dry blasting. Featuring a patent-pending water injection system and Schmidt® Thompson® Valve II, it offers precise control of air, abrasive, and water flows for maximum productivity and minimal material waste. Available in single and dual outlet configurations, all with fork-pocket skid mounts. Key Features:

- Switch between wet blast, dry blast, Softwash™, and blowoff effortlessly.

- Precise water injection for optimal blasting performance and minimal water use

- Supports a wide range of abrasives (coarse and fine)

- High and low-pressure blasting capabilities

- Set and Forget mode switching for consistent performance

- Improved lid construction and quieter blowdown system

- Size Options:

- 1-Outlet, 4.5 cu. ft. Blast Pot | 80-Gallon Water Tank

- 2-Outlet, 6.5 cu. ft. Blast Pot | 165-Gallon Water Tank

- Controls Choices:

- Pneumatic w/Compact BAABS G3 Trigger Deadman

- 12v Electric w/Compact BAABS G3 Trigger Deadman

- Abrasive Cut-Off (ACO) available on 2-outlet 12v Electric

- (The BAABS is the innovative ergonomic system by Schmidt that pairs perfectly with the G3 deadman)

-

The Clemco Wetblast FLEX™ System is a versatile wet and dry blasting solution, designed for maximum flexibility and productivity. Whether you're blasting in dust-sensitive urban areas or open environments requiring dry blasting, the FLEX system adapts to any job, helping you stay compliant, efficient, and profitable. Key Features:

- Switch between wet and dry blasting with ease

- High-performance water injection system for optimal dust suppression

- Precise water adjustment controls for customizable blasting

- 120-gallon water storage tank with pump included for flexible water sourcing

- Easy-to-use controls for quick setup and operation

- Available in Base Unit and Flex Package configurations

-

The Schmidt AmphiBlast™ Mini 1.5 cu. ft. Blast Pot is the most compact and portable wet/dry blasting system in the AmphiBlast family. Designed for high productivity and efficiency, this lightweight unit allows for precise control over air, abrasive, and water flow, minimizing waste and maximizing performance. Available in electric and pneumatic modes, with optional onboard water tank. Key Features:

- Seamlessly switch between wet blast, dry blast, blowoff, and Softwash™

- Minimal water use (less than 1 pint / ½ liter per minute)

- Compact design fits through a 24” doorway (even with onboard tank)

- Schmidt Tera Valve™ XL metering valve for precise abrasive control

- Electric water pump provides high-flow washdown capabilities

- Wide pressure range (10–150 psi) for either delicate or aggressive blasting

-

The Schmidt® AmphiBlast™ Lite 3.5 is a compact, mobile wet/dry abrasive blasting system that delivers precision control, minimal water usage, and high efficiency. Featuring easy mode switching and a dry abrasive tank design, this unit offers cleaner operation and superior performance in both standard blasting and Softwash™ applications. Available Options:

- Models with or without the onboard 15 gallon water tank

- Electric or Pneumatic controls - both with the latest G3 Trigger deadman

- Standard abrasives only, or with Multi-Media technology, allowing the use of all medias regardless of weight, including soda

-

BAUT50G

- Used to store water for use when Wet Blasting

- Often used with the MistBlaster and AirPrep Combination Skid

- Holds up to 50 Gallons

- Mist Blaster uses 1 pint of water per minute when blasting. Should support about 6 hours of wet blasting (not in washdown mode)

- Easy to remove lid for refilling

- Sold Individually

- Genuine BlastOne Product

BAUT50G- Used to store water for use when Wet Blasting

- Often used with the MistBlaster and AirPrep Combination Skid

- Holds up to 50 Gallons

- Mist Blaster uses 1 pint of water per minute when blasting. Should support about 6 hours of wet blasting (not in washdown mode)

- Easy to remove lid for refilling

- Sold Individually

- Genuine BlastOne Product

Wet and dry blasting pots provide unmatched flexibility and efficiency for a wide range of industrial blasting applications. Our collection includes the advanced Mega MistBlaster, versatile Schmidt® AmphiBlast™ Lite, and the reliable Mist Blaster® Wet/Dry Blast Machines. These units offer multiple functions such as mist blasting, dry blasting, wash-down, and blow-off modes, allowing operators to switch between methods effortlessly. Designed for large projects, these pots feature high capacities, robust metering valves, and customizable mounting options, ensuring optimal performance and productivity on the job site.

My Account

My Account

Small Blast Pots

Small Blast Pots Contractor Blast Pots

Contractor Blast Pots Specialty Blast Pots

Specialty Blast Pots Mega Bulk Blasters

Mega Bulk Blasters Robotic / Vertidrive Equipment

Robotic / Vertidrive Equipment Track Blasters

Track Blasters Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Blast Machine Accessories

Blast Machine Accessories