Specialty Blast Pots

Our specialty contractor blast pots are engineered for the toughest industrial environments, providing reliable and efficient solutions for all your blasting needs. From dual outlet blast machines to integrated sponge blasting systems, these pots offer innovative features like pneumatic control systems, moisture separators, and safety enhancements. Ideal for both dry and wet blasting applications, they cater to a wide range of abrasive types and project requirements.

If you need personalized advice or can’t find the exact product you’re looking for, please contact BlastOne or use the live chat feature in the bottom right of your browser window.

Showing all 10 results

-

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

-

The Schmidt® AmphiBlast™ is a versatile, dual-purpose abrasive blasting system designed for efficient wet and dry blasting. Featuring a patent-pending water injection system and Schmidt® Thompson® Valve II, it offers precise control of air, abrasive, and water flows for maximum productivity and minimal material waste. Available in single and dual outlet configurations, all with fork-pocket skid mounts. Key Features:

- Switch between wet blast, dry blast, Softwash™, and blowoff effortlessly.

- Precise water injection for optimal blasting performance and minimal water use

- Supports a wide range of abrasives (coarse and fine)

- High and low-pressure blasting capabilities

- Set and Forget mode switching for consistent performance

- Improved lid construction and quieter blowdown system

- Size Options:

- 1-Outlet, 4.5 cu. ft. Blast Pot | 80-Gallon Water Tank

- 2-Outlet, 6.5 cu. ft. Blast Pot | 165-Gallon Water Tank

- Controls Choices:

- Pneumatic w/Compact BAABS G3 Trigger Deadman

- 12v Electric w/Compact BAABS G3 Trigger Deadman

- Abrasive Cut-Off (ACO) available on 2-outlet 12v Electric

- (The BAABS is the innovative ergonomic system by Schmidt that pairs perfectly with the G3 deadman)

-

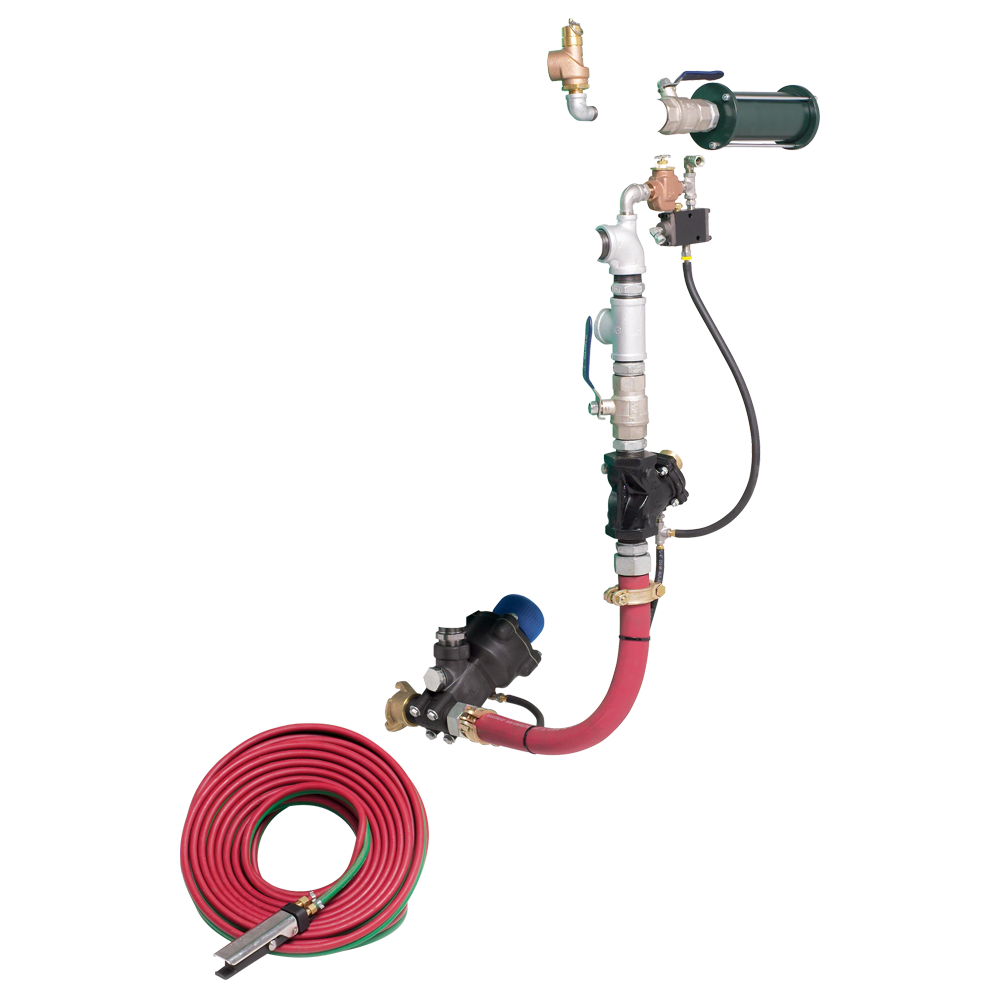

The Clemco Wetblast FLEX™ System is a versatile wet and dry blasting solution, designed for maximum flexibility and productivity. Whether you're blasting in dust-sensitive urban areas or open environments requiring dry blasting, the FLEX system adapts to any job, helping you stay compliant, efficient, and profitable. Key Features:

- Switch between wet and dry blasting with ease

- High-performance water injection system for optimal dust suppression

- Precise water adjustment controls for customizable blasting

- 120-gallon water storage tank with pump included for flexible water sourcing

- Easy-to-use controls for quick setup and operation

- Available in Base Unit and Flex Package configurations

-

The Schmidt AmphiBlast™ Mini 1.5 cu. ft. Blast Pot is the most compact and portable wet/dry blasting system in the AmphiBlast family. Designed for high productivity and efficiency, this lightweight unit allows for precise control over air, abrasive, and water flow, minimizing waste and maximizing performance. Available in electric and pneumatic modes, with optional onboard water tank. Key Features:

- Seamlessly switch between wet blast, dry blast, blowoff, and Softwash™

- Minimal water use (less than 1 pint / ½ liter per minute)

- Compact design fits through a 24” doorway (even with onboard tank)

- Schmidt Tera Valve™ XL metering valve for precise abrasive control

- Electric water pump provides high-flow washdown capabilities

- Wide pressure range (10–150 psi) for either delicate or aggressive blasting

-

The Schmidt® M-Series Multi-Media Blasters are built for pros who need one blast pot that handles it all. From light cleaning with soda to aggressive steel grit work, this series delivers full control, rugged performance, and reliable media flow—job after job.

- Blasts a wide range of abrasives: soda, grit, plastic, glass, and more

- Available with choice of the tried-and-true Thompson II or the latest TeraValve XL, for the ultimate in precision abrasive metering. Both come with a slotted tungsten carbide sleeve.

- G3 Trigger Deadman with Compact BAABS now standard across all models

- Pressure and tank regulators dial in your blast profile for each job. Blasting pressure can be set from 10 to 150 PSI.

- Media vibrator boosts flow performance for lighter abrasives

- Quick-detach valve and media shutoff for simplified service

- Available sizes: Mini M-Series (0.9 cu ft), M-11 (1.5 cu ft), M-21 (2.0 cu ft), M-31 (3.0 cu ft)

-

VCVRS3

- This Blast and Vacuum BRS system is built for high production vacuum blasting work.

- The Vacuum system, blast machine and airdryer are all mounted to one skid.

- The abrasive does not recycle which is ideal when you have very low dust requirements or when your specification calls for the use of virgin abrasive only.

- This system is 100% pnuematic and does not require any electrical power.

- Blast Pot capacity is 3.5 cuft.

- Blast upto 60 sqft / 6 sqm per hour

- Requires 750cfm of air

VCVRS3- This Blast and Vacuum BRS system is built for high production vacuum blasting work.

- The Vacuum system, blast machine and airdryer are all mounted to one skid.

- The abrasive does not recycle which is ideal when you have very low dust requirements or when your specification calls for the use of virgin abrasive only.

- This system is 100% pnuematic and does not require any electrical power.

- Blast Pot capacity is 3.5 cuft.

- Blast upto 60 sqft / 6 sqm per hour

- Requires 750cfm of air

-

ASEPPRO4APKGThe Sponge-Jet B-Vac Pro is a premium system that integrates the 3 essential processes of sponge blasting into a single unit. It is designed to reduce space requirements and deployment time, and is the most popular Sponge-Jet integrated system. Due to it's built-in vacuum system, it reduces the personnel need by 1 person, which makes it price-competitive on jobs of 4+ days duration. Available for purchase or rent. Selected features include:

- Feed Unit. Large capacity pneumatic 470-SJ model with up to 2 hours blasting time.

- Recycler. Pneumatic 50-P recycler with up-sized screen for faster processing.

- Vacuum. With 11 inches of mercury, this powerful vacuum will transport up to 18 lbs of media per minute.

- Lifting frame. The rugged design allows this 6500 lb unit to be transported by forklift or crane. Built-in ladder included.

- Other features. Includes pressure relief valve, high-capacity muffler, secondary moisture separator, and more.

- Selected Options.

- 55-gallon drop-out drum, which when positioned in-line with the vacuum system, reduces the dust loading on the vacuum filter.

- Stand-alone moisture separator. Excellent for use when the primary air dryer is at a distance from the blasting unit.

ASEPPRO4APKGThe Sponge-Jet B-Vac Pro is a premium system that integrates the 3 essential processes of sponge blasting into a single unit. It is designed to reduce space requirements and deployment time, and is the most popular Sponge-Jet integrated system. Due to it's built-in vacuum system, it reduces the personnel need by 1 person, which makes it price-competitive on jobs of 4+ days duration. Available for purchase or rent. Selected features include:- Feed Unit. Large capacity pneumatic 470-SJ model with up to 2 hours blasting time.

- Recycler. Pneumatic 50-P recycler with up-sized screen for faster processing.

- Vacuum. With 11 inches of mercury, this powerful vacuum will transport up to 18 lbs of media per minute.

- Lifting frame. The rugged design allows this 6500 lb unit to be transported by forklift or crane. Built-in ladder included.

- Other features. Includes pressure relief valve, high-capacity muffler, secondary moisture separator, and more.

- Selected Options.

- 55-gallon drop-out drum, which when positioned in-line with the vacuum system, reduces the dust loading on the vacuum filter.

- Stand-alone moisture separator. Excellent for use when the primary air dryer is at a distance from the blasting unit.

-

Portable Sponge-Jet® feed units (aka Sponge Pots) come in a variety of configurations to suit almost every application. From small, value-based units to fully featured machines, sponge feed units are designed for the ultimate in low-dust abrasive blasting. Seven configurations are available, as follows:

- RASP Xtreme™ 3:

- Highly portable & fits thru a 24 inch manway

- Holds 1 bag of new sponge media (5-7 minutes)

- Includes pressure relief valve (PRV) & integrated wheels

- Great for spot work

- 127 lb. empty weight

- 100-HP Feed Unit™:

- Great balance between size, cost & blast time

- Fits through a 30" doorway

- Holds 3 bags of new sponge media

- Includes PRV, secondary moisture separator & wheels

- Great for preservation work

- 480 lb. empty weight

- CG Series (Contractor Grade Series):

- 2 sizes available:

- 170-CG - holds 5 bags of new sponge media

- 470-CG - holds 13 bags of new sponge media

- Value series - ideal where few features are required

- Includes fork pockets

- Great for yard work

- 600 lb. / 1142 lb. empty weights for 170-CG / 470-CG

- 2 sizes available:

- SJ Series (Feed Unit Series):

- 2 sizes available:

- 170-SJ - holds 5 bags of new sponge media

- 170-EX - similar to 170-SJ, but ATEX 2 rated for potentially flammable environments

- 470-SJ - holds 13 bags of new sponge media

- Fully featured, includes:

- Pressure relief valve

- Secondary moisture separator

- Muffler

- Frame w/casters and lifting lugs

- Centralized controls

- Great for field work

- 900 lb / 1000 lb / 1515 lb empty weights respectively

- 2 sizes available:

- RASP Xtreme™ 3:

-

VCBRSMP46FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Blasting rate up to 20 ft2 per hour. Due to this low production rate, this unit is intended for specialty applications, such as spot-work in dust-sensitive areas.

- Utilizes the TeraValve XL abrasive metering valve

- Compressed Air Requirement is only 185 cfm

- Has wheels and fork pockets for easy portability by hand, or by forklift.

- 100% compressed air powered - no electricity required

- Various workheads are available for flat surfaces, inside corners, outside corners, etc. - enquire for details.

- Genuine Products - Manufactured by Schmidt / Axxiom Manufacturing

VCBRSMP46FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Blasting rate up to 20 ft2 per hour. Due to this low production rate, this unit is intended for specialty applications, such as spot-work in dust-sensitive areas.

- Utilizes the TeraValve XL abrasive metering valve

- Compressed Air Requirement is only 185 cfm

- Has wheels and fork pockets for easy portability by hand, or by forklift.

- 100% compressed air powered - no electricity required

- Various workheads are available for flat surfaces, inside corners, outside corners, etc. - enquire for details.

- Genuine Products - Manufactured by Schmidt / Axxiom Manufacturing

Specialty contractor pots are designed to meet the diverse needs of industrial blasting professionals. Our range includes high-capacity blast machines, multi-media soda blasters, and advanced vacuum recovery systems. These products offer flexibility, durability, and efficiency for various blasting applications. Whether you need a compact solution for easy loading or a robust system for high production vacuum blasting, our specialty contractor pots are built to deliver exceptional performance. Featuring advanced metering valves, dual outlets, and versatile mounting options, these machines ensure precise and efficient blasting, reducing downtime and increasing productivity.

My Account

My Account

Small Blast Pots

Small Blast Pots Contractor Blast Pots

Contractor Blast Pots MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Mega Bulk Blasters

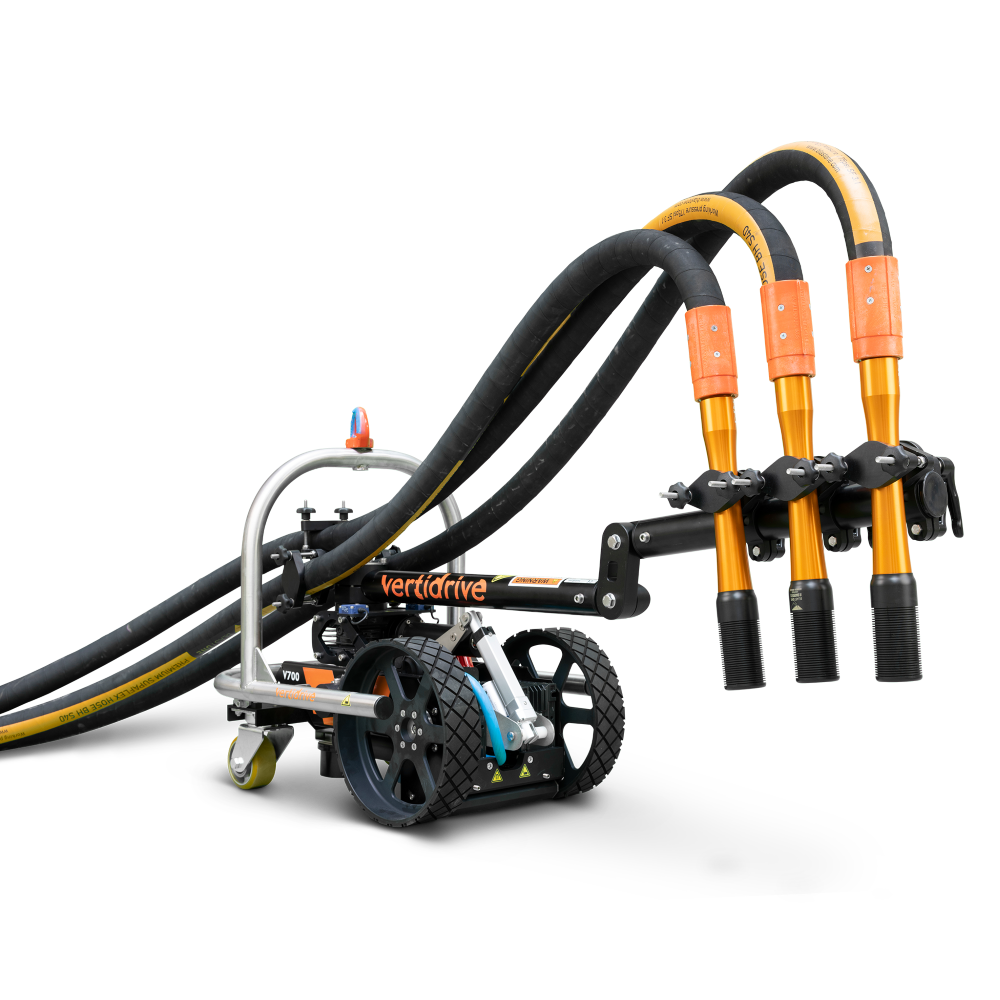

Mega Bulk Blasters Robotic / Vertidrive Equipment

Robotic / Vertidrive Equipment Track Blasters

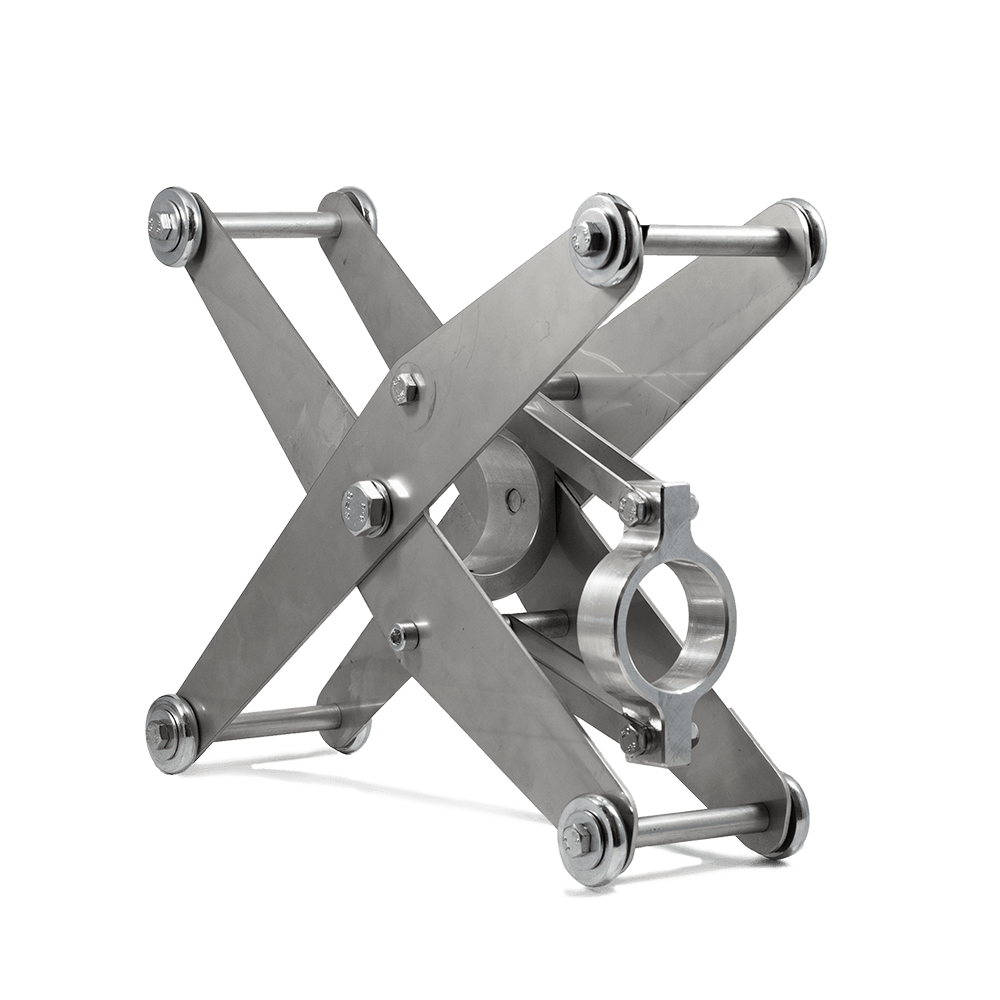

Track Blasters Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Blast Machine Accessories

Blast Machine Accessories