Blast Equipment

Showing 61–75 of 77 results

-

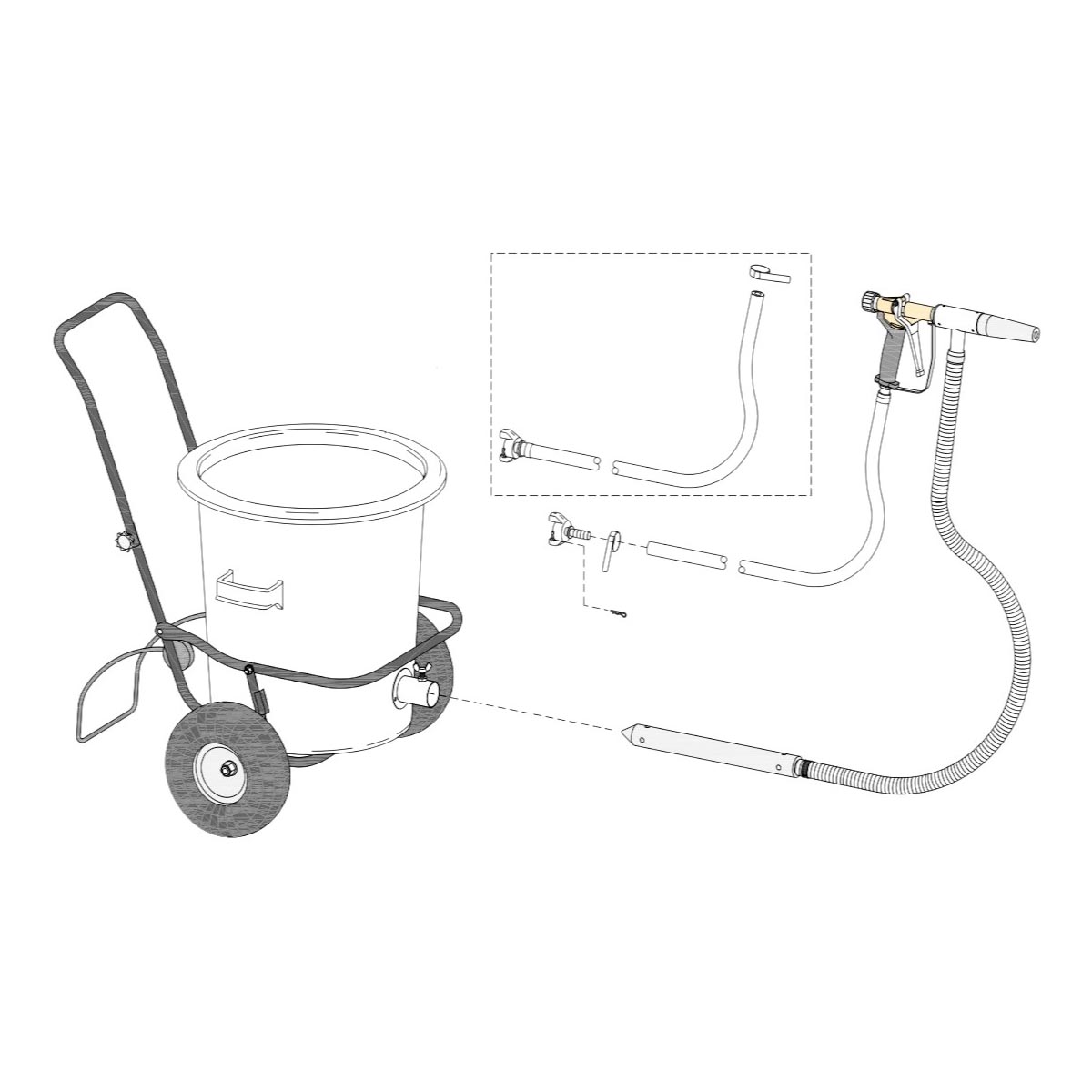

The Clemco Power Suction Gun Packages provide a compact, lightweight suction blasting solution for dry abrasive blasting. Ideal for small jobs or locations where conventional pressure blast setups are inconvenient. Primary Benefits:

- Simple design. No valves, no pressure pots.

- Easy to use. Simply place the suction lance into a bag of abrasive (or into the optional 3cf hopper) to use.

- Highly portable. With an empty weight of 50 pounds including the air / material hose and hopper / cart, the PowerGun package is extremely mobile.

- Power Suction Gun (only), MPN: 100477

- Gun with 16 ft. air/material hoses, MPN: 90253

- Gun with 30 ft. air/material hoses, MPN: 24688

- Gun w/hopper, cart, and 16 ft hoses, MPN: 99860

- Gun w/hopper, cart, and 30 ft hoses, MPN: 24687

- Hopper (3cf) & cart assembly (no gun or hoses), MPN: 99899

-

DM2152ACRK

- Pneumatic Complete Retrofit kit includes:

- Triple-line coupled remote control hose

- Control hose connections for air supply

- Auto air valve and Thompson Valve II metering valve

- Pneumatic push-pull abrasive on-off switch

- Response deadman handle

DM2152ACRK- Pneumatic Complete Retrofit kit includes:

- Triple-line coupled remote control hose

- Control hose connections for air supply

- Auto air valve and Thompson Valve II metering valve

- Pneumatic push-pull abrasive on-off switch

- Response deadman handle

-

- Compatible with a wide range of blast pots

- Digital display of actual blasting time for individual blast outlets

- Allows you to determine productivity, production rates, assisting project costings, job estimates and scheduling maintenance for common wear items

- System available to run off pneumatic and electric deadman controls

- Triggered instantly by the deadman signal, so you get actual blasting hours

- Options available for single and multiple outlets.

-

EB500FOR RENTAL OR PURCHASE

- Ideal for horizontal steel surfaces and marine maintenance

- Center-fed blast wheel design for efficient abrasive propulsion

- Closed-circuit blasting reduces dust and recovery time

- Modular design for easy access in restricted areas

- Blasting speed between 215-377 sq.ft / 20-35 m² per hour

- 15 hp, 460 v, 32 amp, 3-phase power requirements

- 827 lbs./350 kgs weight

- 19"/600 mm manway compatible

- 13¾″/350 mm blasting pattern width

- Compatible with Blastrac EBDC-23 dust collector/vacuum

EB500FOR RENTAL OR PURCHASE- Ideal for horizontal steel surfaces and marine maintenance

- Center-fed blast wheel design for efficient abrasive propulsion

- Closed-circuit blasting reduces dust and recovery time

- Modular design for easy access in restricted areas

- Blasting speed between 215-377 sq.ft / 20-35 m² per hour

- 15 hp, 460 v, 32 amp, 3-phase power requirements

- 827 lbs./350 kgs weight

- 19"/600 mm manway compatible

- 13¾″/350 mm blasting pattern width

- Compatible with Blastrac EBDC-23 dust collector/vacuum

-

EB350FOR RENTAL OR PURCHASE

- The Blastrac EBE 350 is designed for blasting horizontal surfaces

- It is easily dissembled and reassembled for limited access projects such as a storage tank.

- Parts will fit through a 19" Man way

- Blasting Pattern Width of 13-3/4"

- Other Brands and Sizes available - Call us for pricing

EB350FOR RENTAL OR PURCHASE- The Blastrac EBE 350 is designed for blasting horizontal surfaces

- It is easily dissembled and reassembled for limited access projects such as a storage tank.

- Parts will fit through a 19" Man way

- Blasting Pattern Width of 13-3/4"

- Other Brands and Sizes available - Call us for pricing

-

BNATC360BOLT

- Replacement bolt for the Internal Pipe 360° Blast Nozzle

- Sold - individually

BNATC360BOLT- Replacement bolt for the Internal Pipe 360° Blast Nozzle

- Sold - individually

-

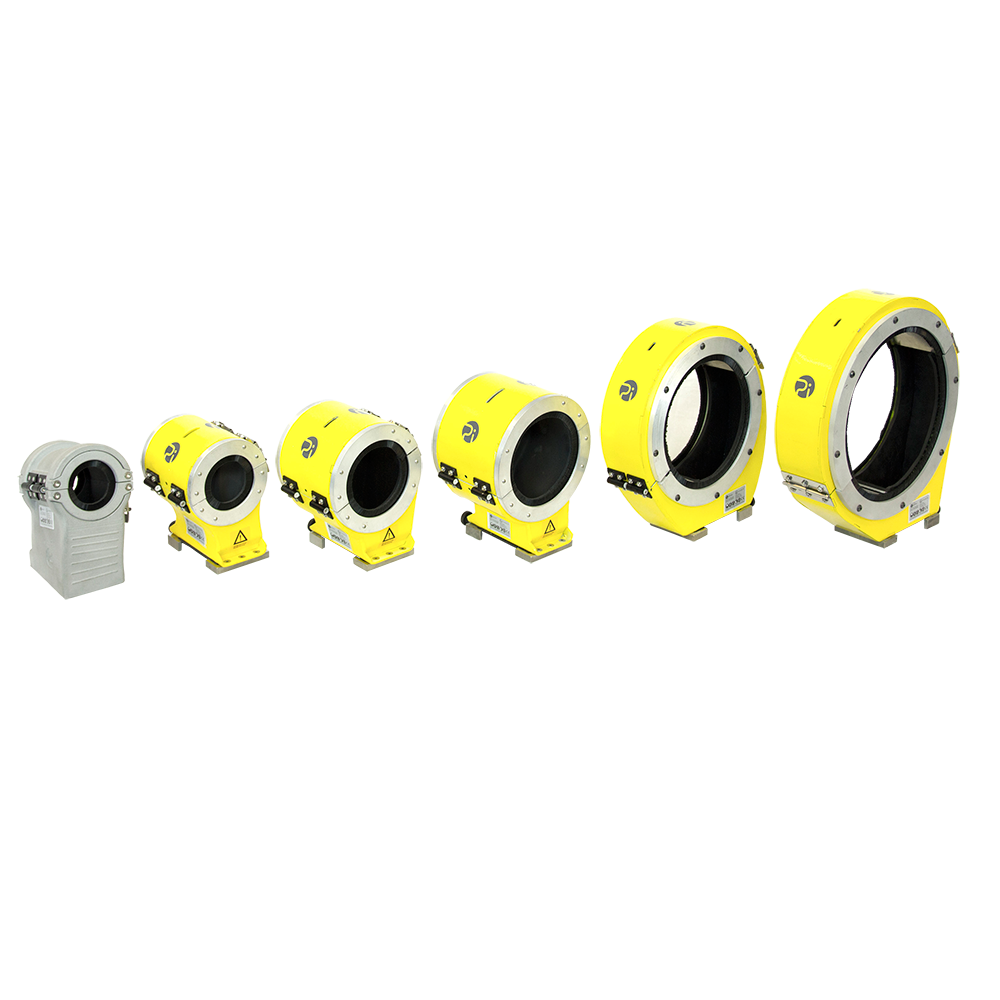

IPRIPTBFOR RENTAL OR PURCHASE

- Ideal for blasting penstocks, tunnels, pipelines, wind towers, etc.

- Offers full 360 degree coverage of pipe internals

- Self-propelled forward or reverse motion

- Can blast pipelines 3' - 32' in diameter

- Lowers labor costs as much as 75% compared with manual blast-pot operations

- Eliminates inconsistencies commonly found with manual blasting

IPRIPTBFOR RENTAL OR PURCHASE- Ideal for blasting penstocks, tunnels, pipelines, wind towers, etc.

- Offers full 360 degree coverage of pipe internals

- Self-propelled forward or reverse motion

- Can blast pipelines 3' - 32' in diameter

- Lowers labor costs as much as 75% compared with manual blast-pot operations

- Eliminates inconsistencies commonly found with manual blasting

-

SBPL01Wall mounted personnel lift, for use in blast rooms. Capable of 3-axis travel, utilizes heavy-duty design to operate in harsh blasting environments.SBPL01Wall mounted personnel lift, for use in blast rooms. Capable of 3-axis travel, utilizes heavy-duty design to operate in harsh blasting environments.

-

SBPL05WElevate your paint booth's efficiency and safety with the Liftman Pneumatic Paint Booth Personnel Manlift, Twin Wheel Version, SKU: SBPL05W. This pneumatic lift is ideal for explosion-sensitive areas, reaching a working height of up to 14' 9".

- Twin Wheel Version for stable and smooth operation.

- Pneumatically operated, ensuring safety in explosive environments.

- Self-centering steering for effortless maneuverability.

- CE, CAS, UL certified and ATEX compliant.

SBPL05WElevate your paint booth's efficiency and safety with the Liftman Pneumatic Paint Booth Personnel Manlift, Twin Wheel Version, SKU: SBPL05W. This pneumatic lift is ideal for explosion-sensitive areas, reaching a working height of up to 14' 9".- Twin Wheel Version for stable and smooth operation.

- Pneumatically operated, ensuring safety in explosive environments.

- Self-centering steering for effortless maneuverability.

- CE, CAS, UL certified and ATEX compliant.

-

BA120000001

- Suits Axxiom/Schmidt Moisture Separators

- Genuine OEM Part

- AFMSH800 and AFMSH1600

- Often purchased with BA7032005 Handle Bar Grip

BA120000001- Suits Axxiom/Schmidt Moisture Separators

- Genuine OEM Part

- AFMSH800 and AFMSH1600

- Often purchased with BA7032005 Handle Bar Grip

-

BA871098627

- Suits Blast Pot timer

- Pressure Switch to allow hour counter to count actual blasting hours

- Working PSI range of 10-150 PSI

- Sold Individually

BA871098627- Suits Blast Pot timer

- Pressure Switch to allow hour counter to count actual blasting hours

- Working PSI range of 10-150 PSI

- Sold Individually

-

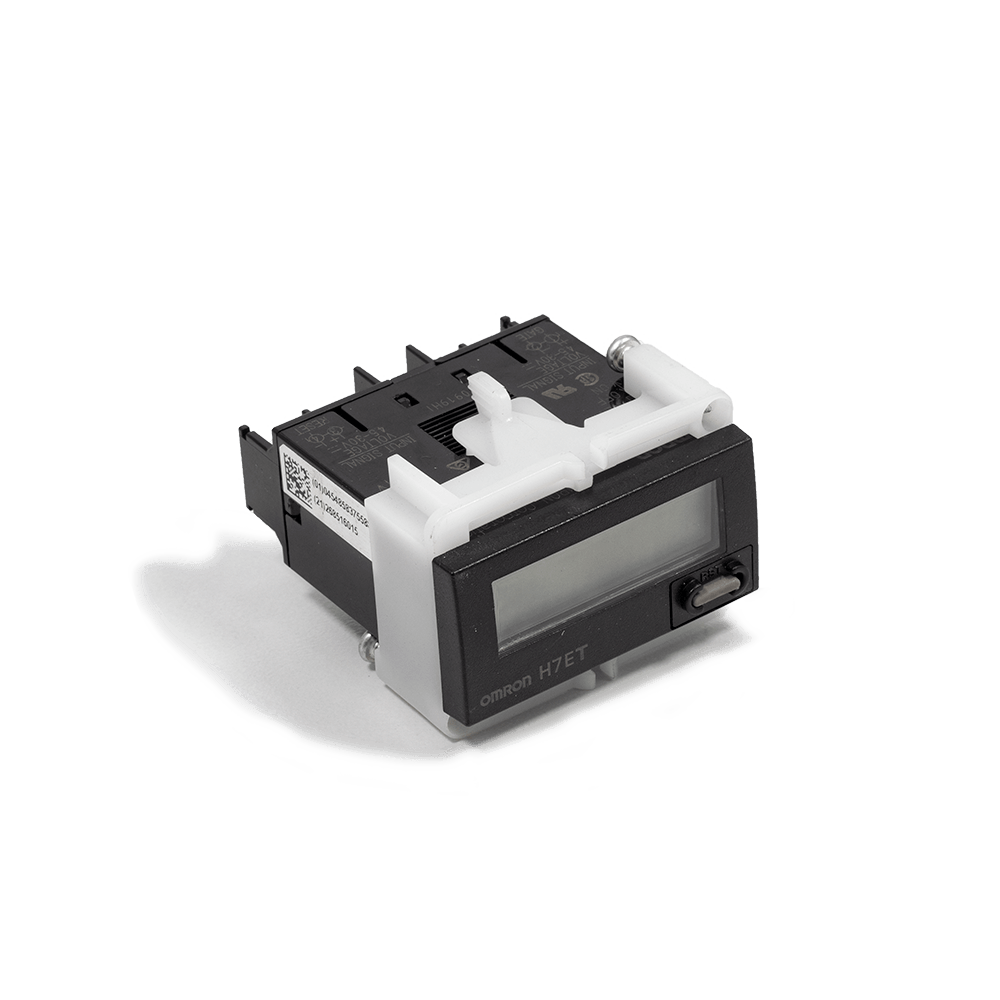

BA7124889

- Suits Blast Pot timer

- Suit No Voltage Applications

- Used to measure actual hours spent blasting

- LCD Timer with Built-In Battery

- Sold Individually

BA7124889- Suits Blast Pot timer

- Suit No Voltage Applications

- Used to measure actual hours spent blasting

- LCD Timer with Built-In Battery

- Sold Individually

-

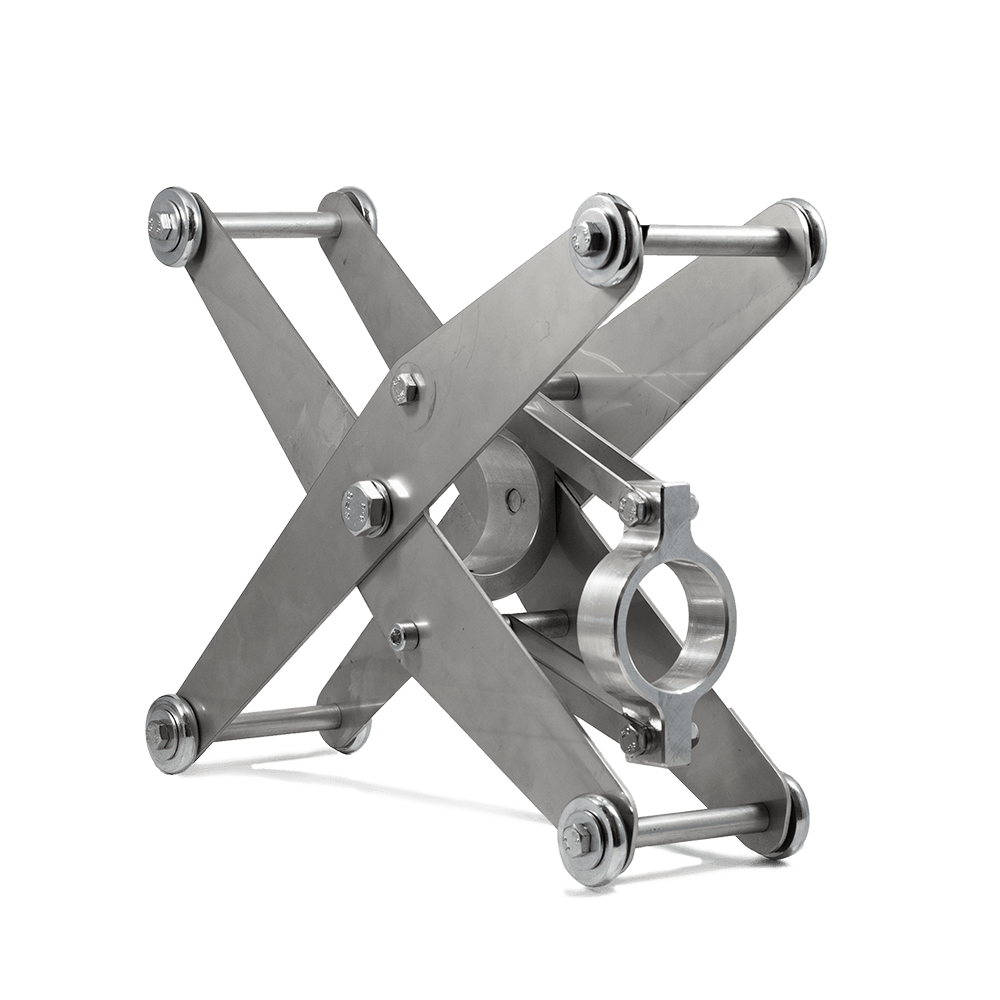

BAWH10110V

- Designed for use with the rotorblast and cone blasters when ID blasting

- Semi-automatically feeds the blast hose at a consistent rate through the pipe being blasted

- Ensures a consistent blast pattern vs manual handling of the hose

BAWH10110V- Designed for use with the rotorblast and cone blasters when ID blasting

- Semi-automatically feeds the blast hose at a consistent rate through the pipe being blasted

- Ensures a consistent blast pattern vs manual handling of the hose

My Account

My Account

MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Small Portable Blast Pots

Small Portable Blast Pots Specialty Contractor Pots

Specialty Contractor Pots Robotic / VertiDrive UHP Equipment

Robotic / VertiDrive UHP Equipment Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Mega Bulk Blasters

Mega Bulk Blasters Track Blasters

Track Blasters