Blast Equipment

Showing 46–60 of 77 results

-

HTIBIX06EBFOR RENTAL OR PURCHASE

-

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

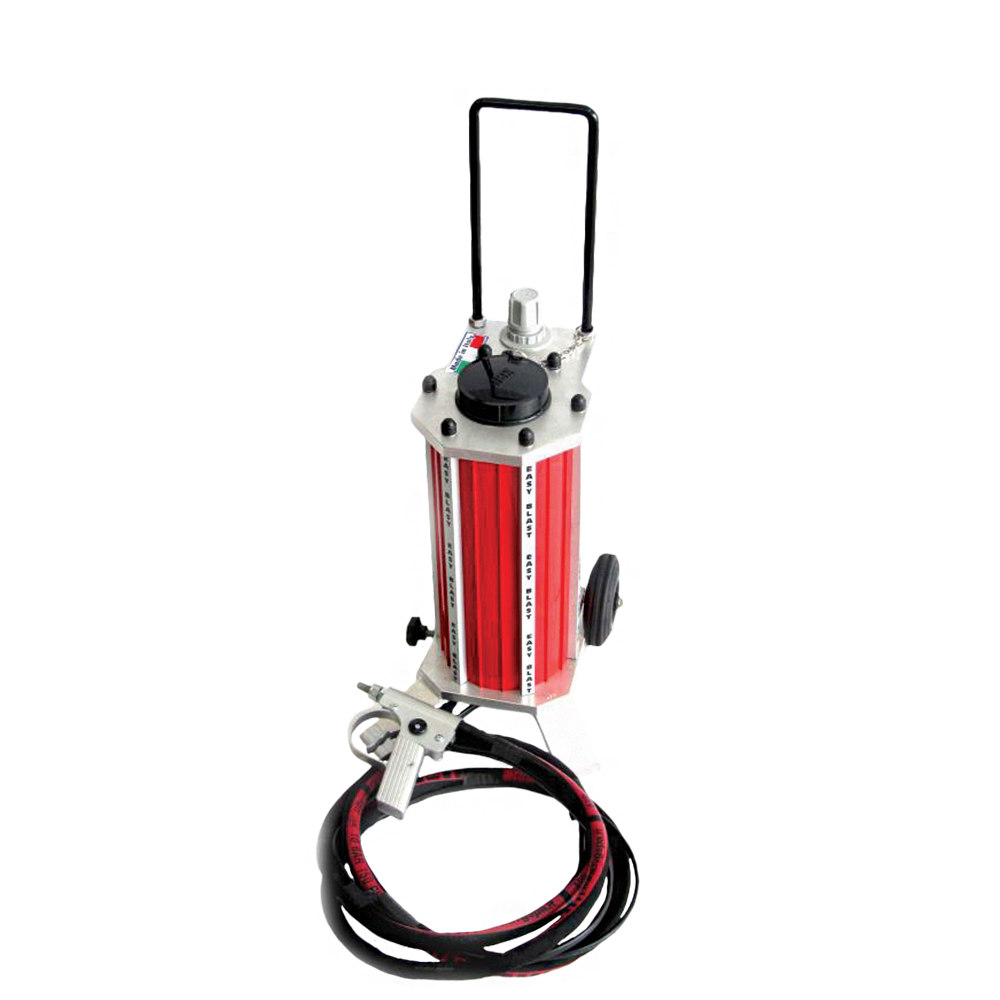

- The IBIX 6 Blaster is a portable abrasive blasting system.

- Very light - Empty Weight is only 27lbs

- Ideal for touch-up and maintenance work.

- It's portability makes blasting in difficult access areas possible.

- Sold as a Kit with a 25' hose and application gun 1/8" nozzle.

- Genuine Parts - Manufactured by IBIX

-

HTIBIX06EBFOR RENTAL OR PURCHASE-

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- The IBIX 6 Blaster is a portable abrasive blasting system.

- Very light - Empty Weight is only 27lbs

- Ideal for touch-up and maintenance work.

- It's portability makes blasting in difficult access areas possible.

- Sold as a Kit with a 25' hose and application gun 1/8" nozzle.

- Genuine Parts - Manufactured by IBIX

-

-

-

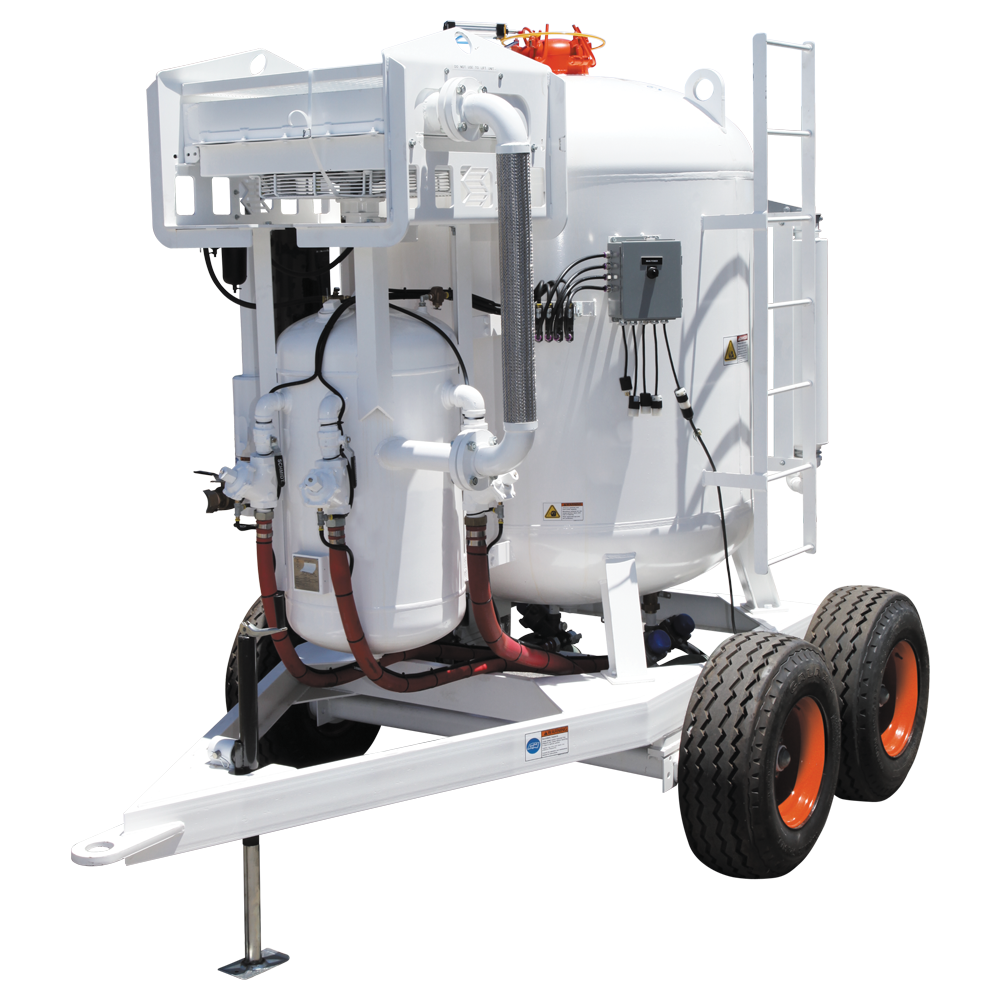

Axxiom / Schmidt High Production work-horse for big dry-blast projects! Save time and money when doing large projects.

- Industrial Quality & Design - Manufactured by Schmidt to BlastOne specifications

- Long-life TeraValve metering valves - typically 4-outlets

- High-flow plumbing virtually eliminates pressure drop

- Huge abrasive capacity - Up to 160 cubic feet (aka 8-ton pot) holds half a truckload of garnet! Also available in 120cf, 60cf and 45cf sizes.

- Flexible configuration - Available with:

- Highway Trailer

- Yard Trailer

- Skid mount

- Shipping Legs (for mounting on your own equipment)

- Latest Latest-generation safety features

- HALOK® closure - impossible to open under pressure

- CEN muffler - reduces noise AND prevents freeze-up

- Anti-slip ladder rungs

- Available Performance Enhancing Options

- Bulk Bag Loading Rack - enhances safety while loading

- Hybrid - attached dryer saves space & setup time

- Vacuum loading - saves wait time for cranes where forklift loading of abrasive is prohibited

- Hour meters - management tool monitors nozzle time

Favorite for use with the VertiDrive robots! Rent or purchase. Note: Designed to be used with a 1600 CFM dryer, available here.

- Industrial Quality & Design - Manufactured by Schmidt to BlastOne specifications

-

BA840001873

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- Improves safety when loading abrasive into Mega Blaster

- Heavy-duty steel cage prevents possibility of bulk bag dropping while loading

- Designed for Schmidt 160 C.F. pot. Other configurations available - enquire.

BA840001873- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- Improves safety when loading abrasive into Mega Blaster

- Heavy-duty steel cage prevents possibility of bulk bag dropping while loading

- Designed for Schmidt 160 C.F. pot. Other configurations available - enquire.

-

BMS1602TVH1600BULKBLASTER / MEGABLASTER

- Specified capacity 160 cu ft / 4500 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 23800 lbs / 10.8 tonne

- 1600 cfm Airprep™ mounted directly on the front of the MegaBlaster

- Comes with 2 Thompson® Valve metering valves, up to 4 outlets possible

- Skid or Trailer Mounted

- Hybrid Bulk Blaster with built-in Air Dryer

BMS1602TVH1600BULKBLASTER / MEGABLASTER- Specified capacity 160 cu ft / 4500 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 23800 lbs / 10.8 tonne

- 1600 cfm Airprep™ mounted directly on the front of the MegaBlaster

- Comes with 2 Thompson® Valve metering valves, up to 4 outlets possible

- Skid or Trailer Mounted

- Hybrid Bulk Blaster with built-in Air Dryer

-

The latest innovation in deadman safety technology from Axxiom is the BAABS (Blasting Accessories and Assist Bracket System). Intended to be the safest deadman on the market, it mechanically prevents inadvertent activation. The Schmidt BAABS deadman is such a leap forward in safety technology that Axxiom provides them as standard equipment with most new blast pot or valve retrofit purchases.*

All BAABS use the Axxiom G3 trigger deadman configurable as either electric or pneumatic.

All BAABS units are capable of being fitted with the BAABS blast light for improved vision in dim or dusty environments. (Note: When the light is used with the Subcompact BAABS, there is not room for the thrust brace.)

*The standard configuration provided with new equipment is the Compact size. See Product Description tab for all size options.

-

RUBVDV700

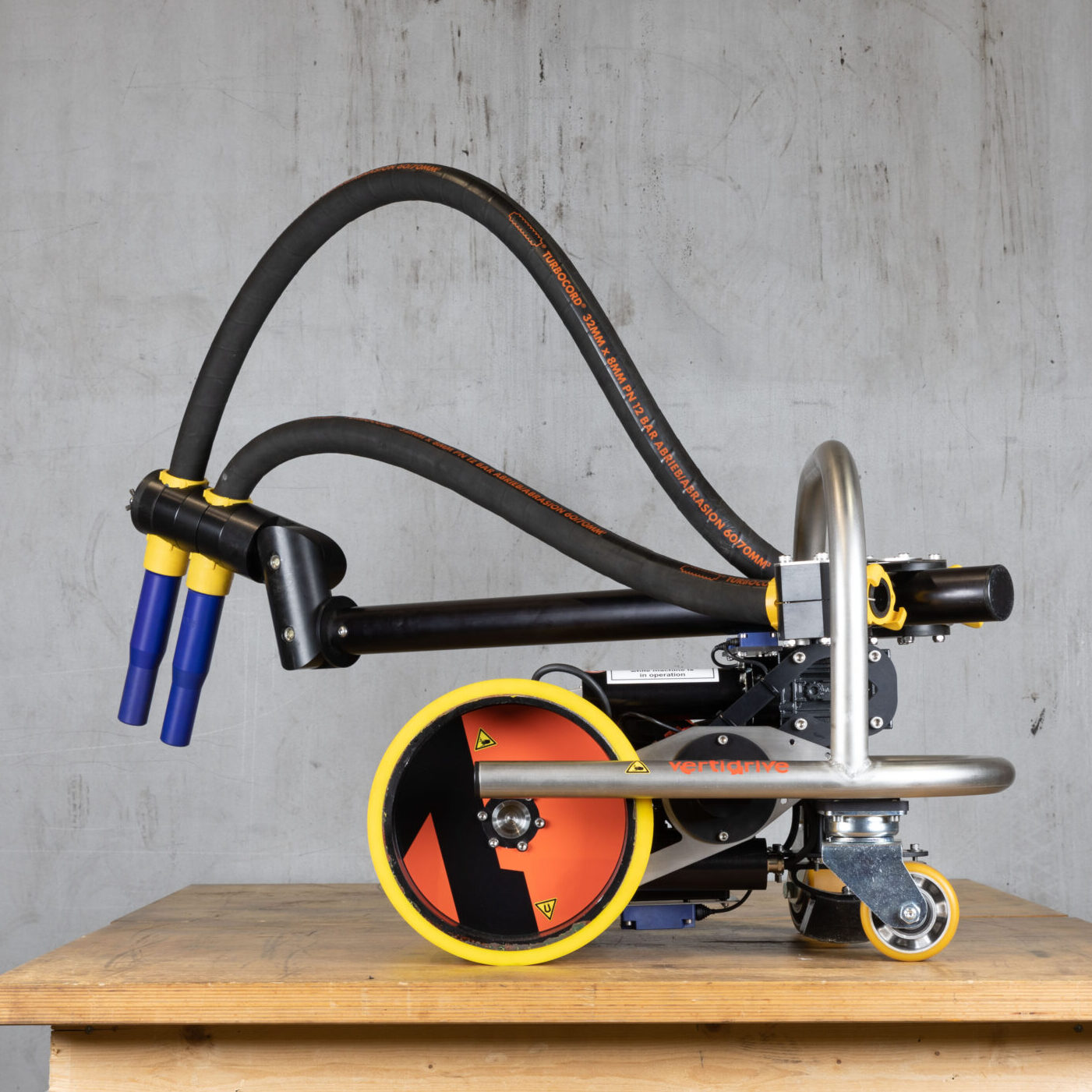

BlastOne's VertiDrive V700 Blasting Robot represents the cutting edge in surface preparation technology, engineered to revolutionize large-scale blasting projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for performance, efficiency, and safety.

RENT or PURCHASE this surface preparation work-horse! The next-generation V700 VertiDrive. Boosting performance and profits on large blasting projects. Purchase pricing is typically between $125,000 and $204,000, depending on configuration. BlastOne can provide on-site training and ongoing support to ensure maximum productivity from Day 1. Schedule a call with our SMEs to calculate and expected ROI for your next project.

- Faster Production. Now holds up to 3 nozzles and each nozzle is up to 30% faster than the best hand blasting. Highest productivity of any robotic blasting system!

- Cleaner Surface. Provides consistent blasting quality by adjustment of equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and now even upside-down!

- Versatile. The V700 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Ultra High Pressure (UHP) coating removal.

- Power Wash surface cleaning.

- Reduced Cost-of-Ownership. The VertiDrive V700 has the lowest maintenance cost of any blasting robot.

- Looking for more information? Click here to read more…

Note: We recommend that this equipment be used on large, flat surfaces (like tanks or ship hulls) and can deliver cost savings on projects as small as 10,000 square feet. Not all medias can be used with the VertiDrive. Can be used with existing blast or UHP equipment, or BlastOne can provide new and updated equipment.

RUBVDV700BlastOne's VertiDrive V700 Blasting Robot represents the cutting edge in surface preparation technology, engineered to revolutionize large-scale blasting projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for performance, efficiency, and safety.

RENT or PURCHASE this surface preparation work-horse! The next-generation V700 VertiDrive. Boosting performance and profits on large blasting projects. Purchase pricing is typically between $125,000 and $204,000, depending on configuration. BlastOne can provide on-site training and ongoing support to ensure maximum productivity from Day 1. Schedule a call with our SMEs to calculate and expected ROI for your next project.

- Faster Production. Now holds up to 3 nozzles and each nozzle is up to 30% faster than the best hand blasting. Highest productivity of any robotic blasting system!

- Cleaner Surface. Provides consistent blasting quality by adjustment of equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and now even upside-down!

- Versatile. The V700 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Ultra High Pressure (UHP) coating removal.

- Power Wash surface cleaning.

- Reduced Cost-of-Ownership. The VertiDrive V700 has the lowest maintenance cost of any blasting robot.

- Looking for more information? Click here to read more…

Note: We recommend that this equipment be used on large, flat surfaces (like tanks or ship hulls) and can deliver cost savings on projects as small as 10,000 square feet. Not all medias can be used with the VertiDrive. Can be used with existing blast or UHP equipment, or BlastOne can provide new and updated equipment.

-

RUBVDM71

BlastOne's VertiDrive M7 Blasting Robot is an innovative surface preparation powerhouse, engineered to revolutionize large-scale blasting projects. This advanced robotic system, developed exclusively by BlastOne, sets a new benchmark for efficiency, consistency, and safety in industrial surface treatment.

RENT or PURCHASE this surface preparation work-horse! The original M7 VertiDrive. Bringing improved production to large blasting projects.

- Faster Production. Holds 2 nozzles simultaneously and each nozzle is up to 30% faster than the best hand blasting.

- Cleaner Surface. Provides consistent blasting quality by adjusting equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Blast both horizontal and vertical surfaces with ease.

- Versatile. The M7 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Power Wash surface cleaning

- Ultra High Pressure (UHP) coating removal.

Note: we recommend that this equipment be used on large, flat surfaces (like tanks or ship hulls) with at least 10,000 square feet to recognize cost savings. Not all medias can be used with the VertiDrive. Can be used with existing blast equipment, or BlastOne can provide. Purchase pricing is typically between $125,000 and $204,000, depending on configuration. BlastOne offers on-site training to help maximize your investment. Contact us to discuss your specific project and estimate the ROI by using a VertiDrive.

RUBVDM71BlastOne's VertiDrive M7 Blasting Robot is an innovative surface preparation powerhouse, engineered to revolutionize large-scale blasting projects. This advanced robotic system, developed exclusively by BlastOne, sets a new benchmark for efficiency, consistency, and safety in industrial surface treatment.

RENT or PURCHASE this surface preparation work-horse! The original M7 VertiDrive. Bringing improved production to large blasting projects.

- Faster Production. Holds 2 nozzles simultaneously and each nozzle is up to 30% faster than the best hand blasting.

- Cleaner Surface. Provides consistent blasting quality by adjusting equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Blast both horizontal and vertical surfaces with ease.

- Versatile. The M7 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Power Wash surface cleaning

- Ultra High Pressure (UHP) coating removal.

Note: we recommend that this equipment be used on large, flat surfaces (like tanks or ship hulls) with at least 10,000 square feet to recognize cost savings. Not all medias can be used with the VertiDrive. Can be used with existing blast equipment, or BlastOne can provide. Purchase pricing is typically between $125,000 and $204,000, depending on configuration. BlastOne offers on-site training to help maximize your investment. Contact us to discuss your specific project and estimate the ROI by using a VertiDrive.

-

RUBVDV400

BlastOne's VertiDrive V400 Closed-Loop UHP Robot represents the pinnacle of surface preparation technology, engineered to revolutionize large-scale Ultra High Pressure (UHP) projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for efficiency, cleanliness, and safety in industrial surface treatment.

RENT or PURCHASE this surface preparation work-horse! The next-generation V400 Ultra High Pressure VertiDrive. Bringing enhanced technology to closed-loop UHP projects.

- Faster. V400 robotic technology is up to 5X faster than manual work.

- Cleaner. The rust, coatings, and contaminants are removed and returned to the vacuum via the closed-circuit system.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and even upside-down!

- Environmentally friendly. Contaminants don't just fall to the surface or blow away in the wind. The V400 brings them back to the vacuum source for responsible disposal.

- Productive. Has an extra-wide 15.5" (400 mm) cleaning width

Note: UHP does not create surface profile , but exposes the existing profile. We recommend that this equipment be used on large, flat surfaces (like tanks or ship hulls) with at least 10,000 square feet to realize cost savings. Can be used with existing UHP pumps or BlastOne can arrange. Purchase pricing is typically between $165,000 and $204,000 depending on configuration. BlastOne can provide on-site training and ongoing support to ensure maximum productivity from Day 1. Schedule a call with our SMEs to calculate an expected ROI for your next project.

RUBVDV400BlastOne's VertiDrive V400 Closed-Loop UHP Robot represents the pinnacle of surface preparation technology, engineered to revolutionize large-scale Ultra High Pressure (UHP) projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for efficiency, cleanliness, and safety in industrial surface treatment.

RENT or PURCHASE this surface preparation work-horse! The next-generation V400 Ultra High Pressure VertiDrive. Bringing enhanced technology to closed-loop UHP projects.

- Faster. V400 robotic technology is up to 5X faster than manual work.

- Cleaner. The rust, coatings, and contaminants are removed and returned to the vacuum via the closed-circuit system.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and even upside-down!

- Environmentally friendly. Contaminants don't just fall to the surface or blow away in the wind. The V400 brings them back to the vacuum source for responsible disposal.

- Productive. Has an extra-wide 15.5" (400 mm) cleaning width

Note: UHP does not create surface profile , but exposes the existing profile. We recommend that this equipment be used on large, flat surfaces (like tanks or ship hulls) with at least 10,000 square feet to realize cost savings. Can be used with existing UHP pumps or BlastOne can arrange. Purchase pricing is typically between $165,000 and $204,000 depending on configuration. BlastOne can provide on-site training and ongoing support to ensure maximum productivity from Day 1. Schedule a call with our SMEs to calculate an expected ROI for your next project.

-

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

-

VCBRSMP46FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Blasting rate up to 20 ft2 per hour. Due to this low production rate, this unit is intended for specialty applications, such as spot-work in dust-sensitive areas.

- Utilizes the TeraValve XL abrasive metering valve

- Compressed Air Requirement is only 185 cfm

- Has wheels and fork pockets for easy portability by hand, or by forklift.

- 100% compressed air powered - no electricity required

- Various workheads are available for flat surfaces, inside corners, outside corners, etc. - enquire for details.

- Genuine Products - Manufactured by Schmidt / Axxiom Manufacturing

VCBRSMP46FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Blasting rate up to 20 ft2 per hour. Due to this low production rate, this unit is intended for specialty applications, such as spot-work in dust-sensitive areas.

- Utilizes the TeraValve XL abrasive metering valve

- Compressed Air Requirement is only 185 cfm

- Has wheels and fork pockets for easy portability by hand, or by forklift.

- 100% compressed air powered - no electricity required

- Various workheads are available for flat surfaces, inside corners, outside corners, etc. - enquire for details.

- Genuine Products - Manufactured by Schmidt / Axxiom Manufacturing

-

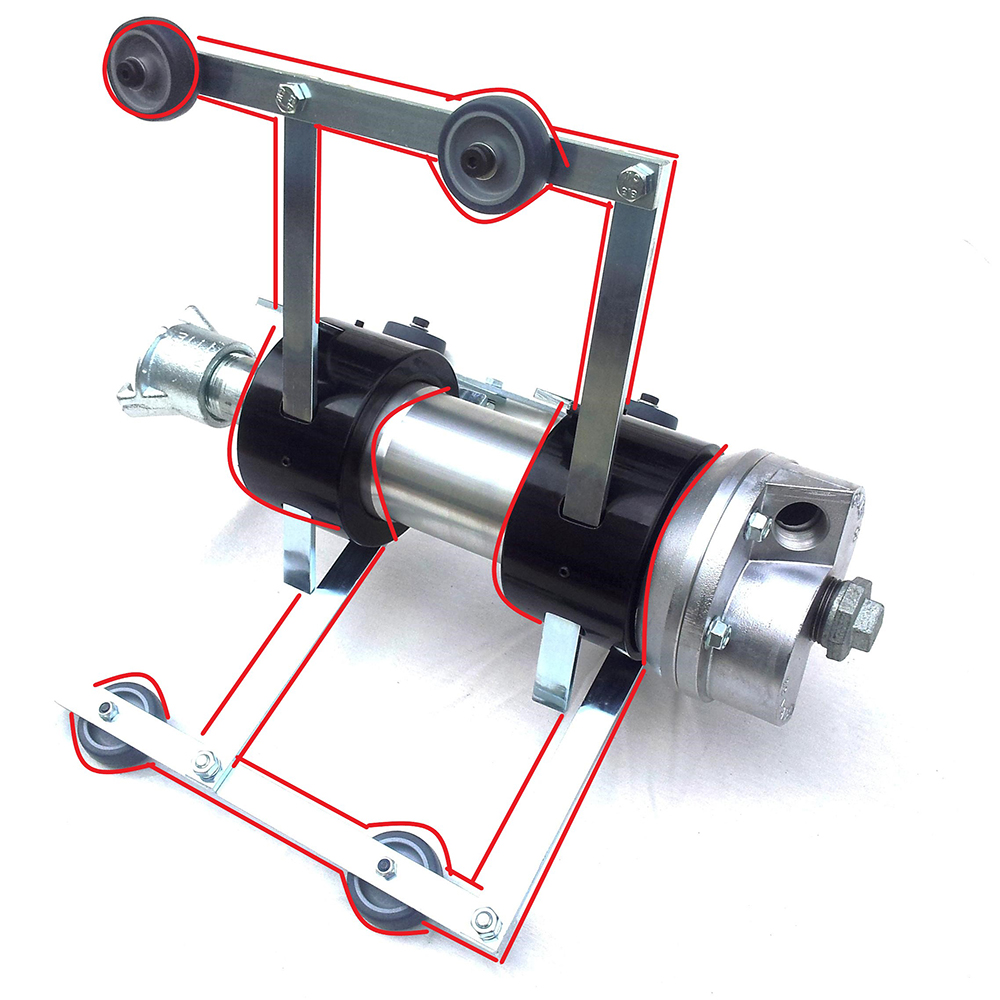

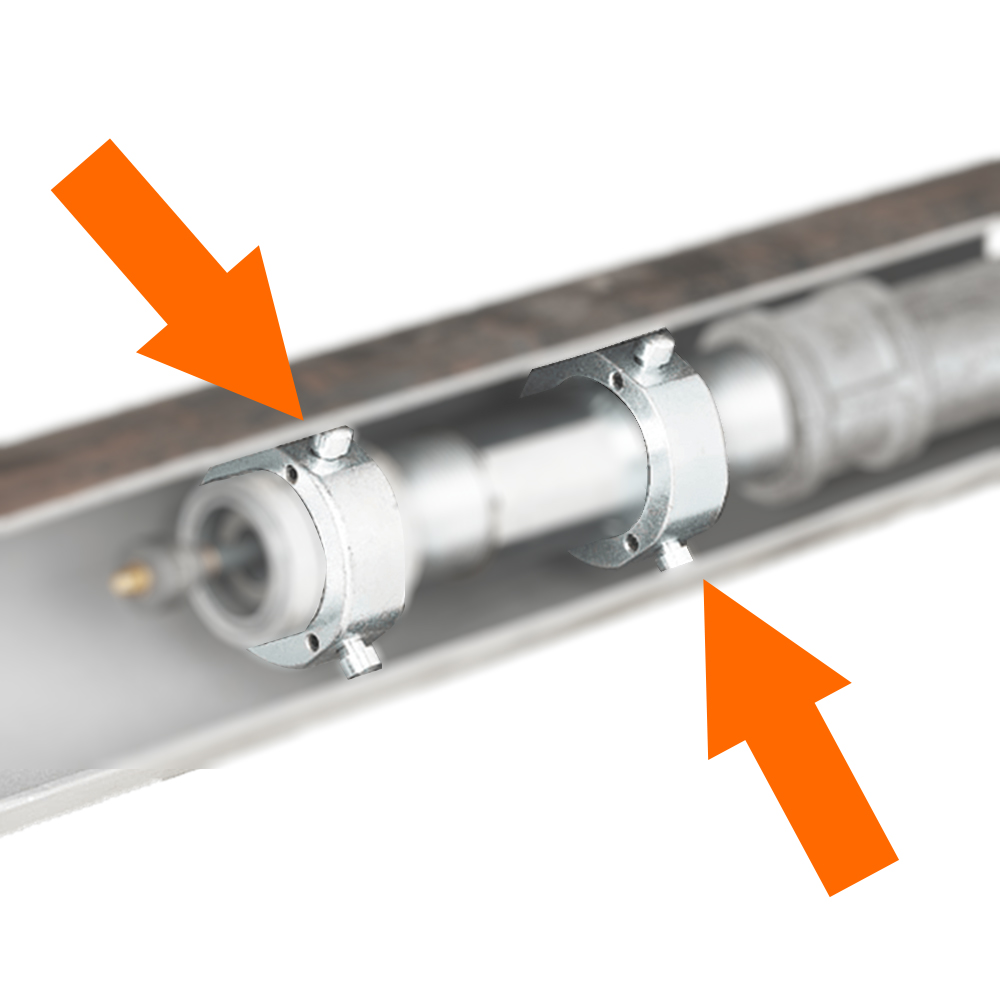

IPC1200

- Fits to IPC1000 as one assembly (outlined in red in image)

- Suitable for pipes between 8" and 36" in diameter

- Consists of 2 collars, 3 two-wheel roller bars and 4 sets of centering legs (6 legs per set)

IPC1200- Fits to IPC1000 as one assembly (outlined in red in image)

- Suitable for pipes between 8" and 36" in diameter

- Consists of 2 collars, 3 two-wheel roller bars and 4 sets of centering legs (6 legs per set)

-

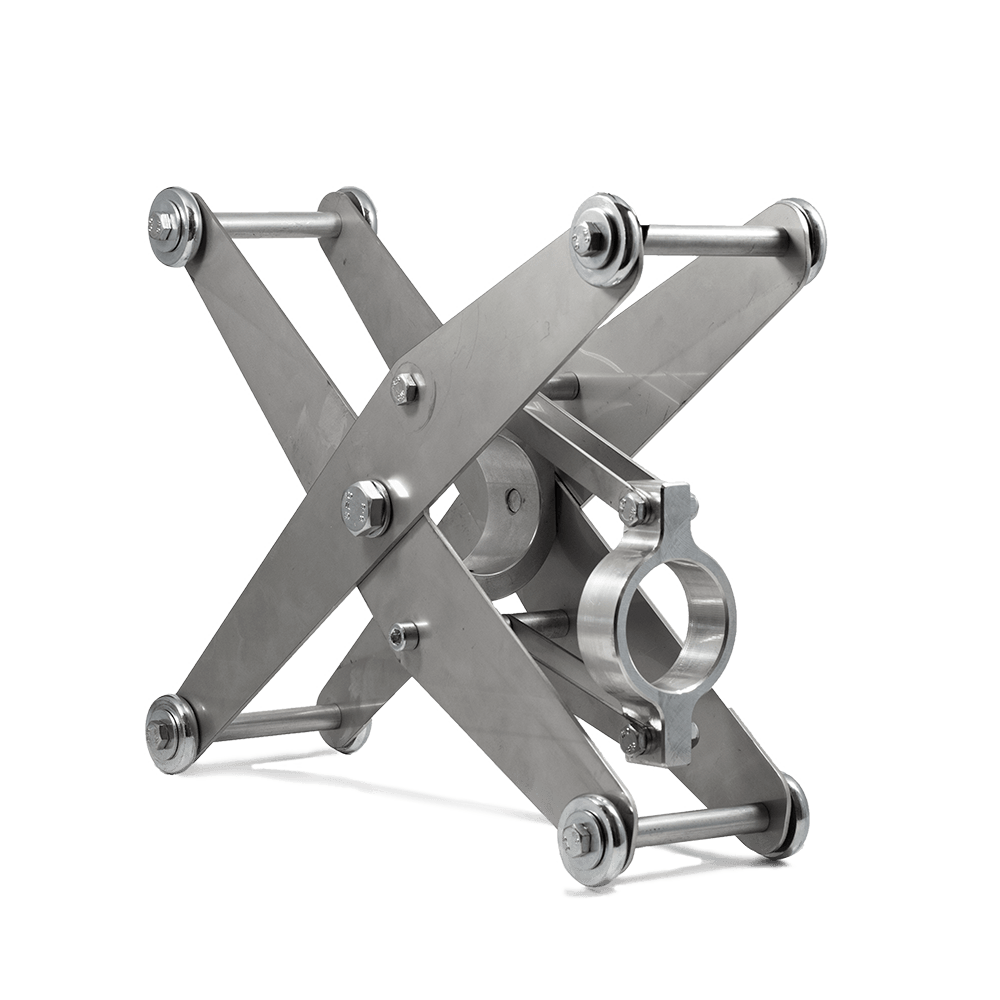

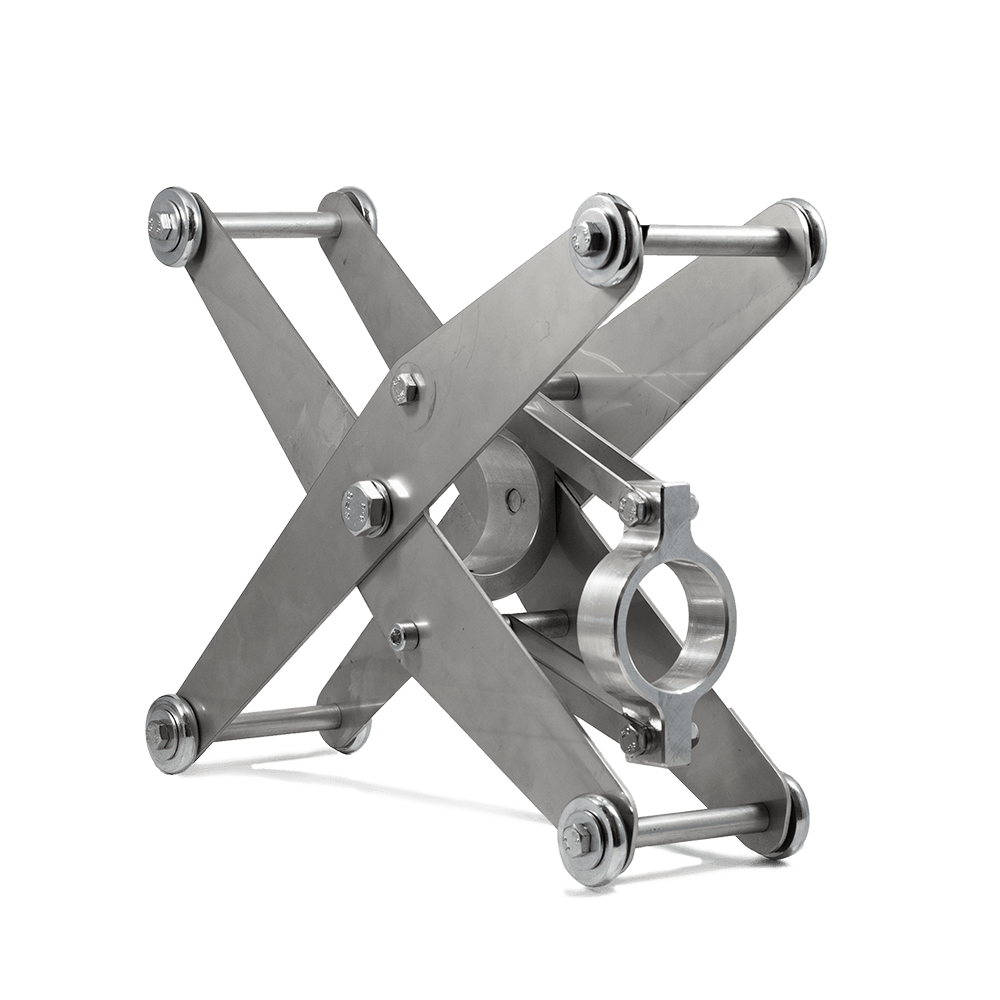

IPC4200

- Suits IPC4000 and IPC4500 ConeBlast Pipe Blasting System

- Ideal for blasting pipes between 5'' - 12'' internal diameter

- 'Scissor Type' Centering Carriage

- Sold Individually

IPC4200- Suits IPC4000 and IPC4500 ConeBlast Pipe Blasting System

- Ideal for blasting pipes between 5'' - 12'' internal diameter

- 'Scissor Type' Centering Carriage

- Sold Individually

-

HT3202404T

-

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- 8" cutting width

- Easy to use, maintain and maneuver

- Precise screw type scaling head adjustment

- Angled dust port allows connection of industrial dust collector giving virtually dust free performance

- Supplied complete & ready to work with cutter head

- Updated version with improved electrics and start switch

-

HT3202404T-

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- 8" cutting width

- Easy to use, maintain and maneuver

- Precise screw type scaling head adjustment

- Angled dust port allows connection of industrial dust collector giving virtually dust free performance

- Supplied complete & ready to work with cutter head

- Updated version with improved electrics and start switch

-

-

-

CAPSG02641Designed for abrasive blasting applications with limited air supply, the Suction Blaster is intended for small projects / touch-up work, etc. This complete setup (compressor and abrasive not included) can blast with as little as 12 cfm, using the included #5 nozzle and 1/8" air jet. The package includes the following:

- Light-duty, portable hopper with top screen

- SG-300 blast gun with #5 nozzle and 1/8" air jet

- 10' air hose, 1/2" ID

- 10' blast hose, 1/2" ID

- Package as shown MPN: 02641

CAPSG02641Designed for abrasive blasting applications with limited air supply, the Suction Blaster is intended for small projects / touch-up work, etc. This complete setup (compressor and abrasive not included) can blast with as little as 12 cfm, using the included #5 nozzle and 1/8" air jet. The package includes the following:- Light-duty, portable hopper with top screen

- SG-300 blast gun with #5 nozzle and 1/8" air jet

- 10' air hose, 1/2" ID

- 10' blast hose, 1/2" ID

- Package as shown MPN: 02641

My Account

My Account

MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Small Portable Blast Pots

Small Portable Blast Pots Specialty Contractor Pots

Specialty Contractor Pots Robotic / VertiDrive UHP Equipment

Robotic / VertiDrive UHP Equipment Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Mega Bulk Blasters

Mega Bulk Blasters Track Blasters

Track Blasters