Blast Equipment

-

SBMGZ

- Custom designed blasting and painting facilities, sized as large as application requires

- Ideal for new construction and repair, for vessels of all type and size

- Available configurations:

- Hybrid blast/paint hall - single hall for both operations at different times

- 2 separate halls - each single-purpose hall dedicated to blasting or painting

- Available with completely controllable environmental conditions to meet required specifications

- Compatible with abrasive recovery and recycling equipment with many available configurations

SBMGZ- Custom designed blasting and painting facilities, sized as large as application requires

- Ideal for new construction and repair, for vessels of all type and size

- Available configurations:

- Hybrid blast/paint hall - single hall for both operations at different times

- 2 separate halls - each single-purpose hall dedicated to blasting or painting

- Available with completely controllable environmental conditions to meet required specifications

- Compatible with abrasive recovery and recycling equipment with many available configurations

-

SBMGWThese blast rooms are designed to improve flow in a Wind Tower manufacturing facility, and can be made to handle both internal and exterior blast, with nearly any level of automation.SBMGWThese blast rooms are designed to improve flow in a Wind Tower manufacturing facility, and can be made to handle both internal and exterior blast, with nearly any level of automation.

-

Large Fabric Lift-Up Doors are a high-performance solution designed for blast and paint booths, especially in demanding shipyard environments. These durable and space-efficient doors provide superior sealing, weather resistance, and customizable dimensions to handle the largest ship components. They ensure operational efficiency and controlled environments for industrial applications.

Key Features:

- Vertical lift design maximizes floor and wall space for efficient operations.

- Heavy-duty fabric construction reinforced with steel frames for durability.

- Customizable dimensions for seamless access to large-scale projects.

- Superior sealing to maintain controlled environments for blasting or painting.

- Weather-resistant and designed to withstand harsh industrial conditions.

- Equipped with safety systems, high-speed motors, and precision controls.

-

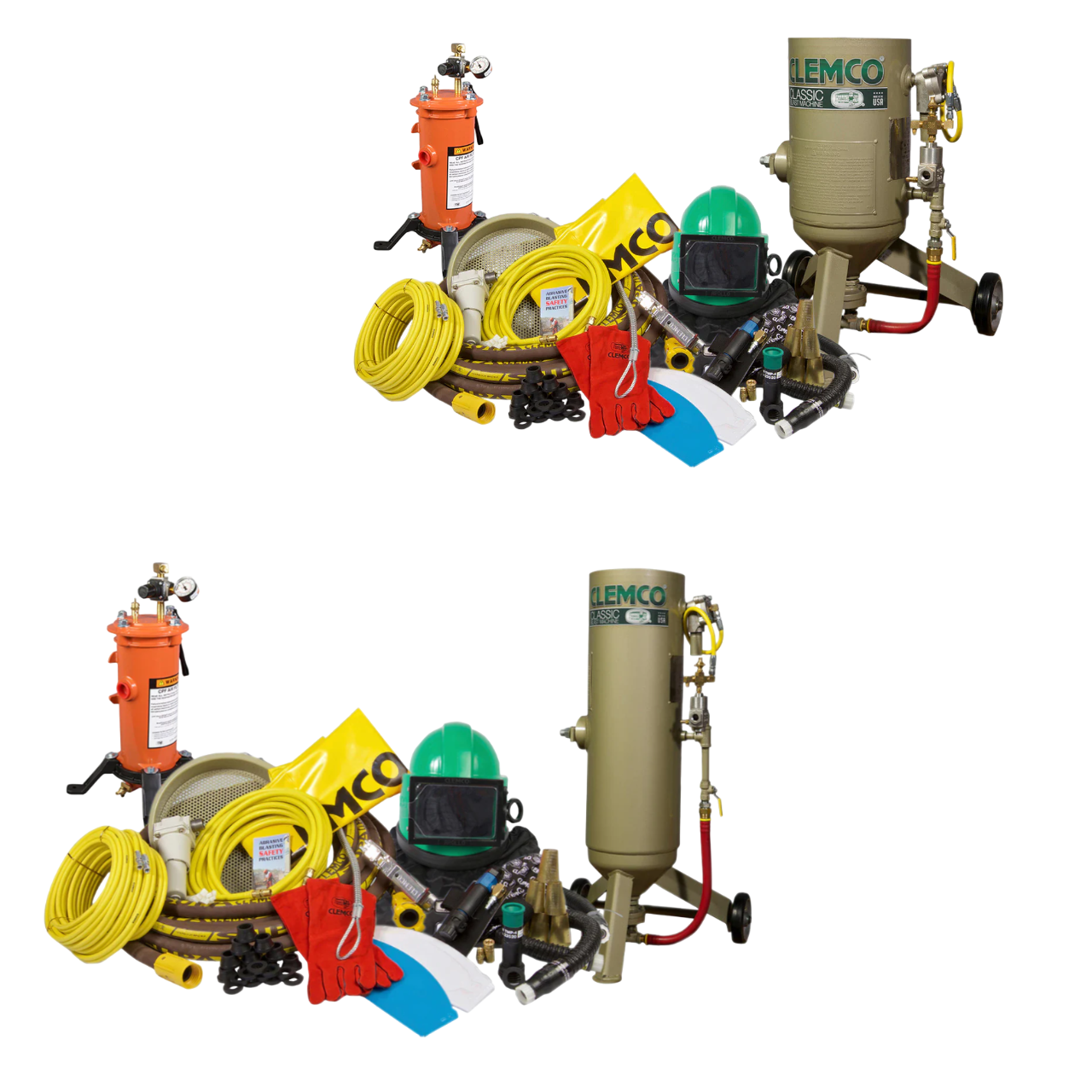

Clemco Industries is the world's largest manufacturer of air-powered blasting equipment. It is over 80 years old, being founded in 1941. Clemco offers two series of blast machines - the Classic and the Contractor Pots. While both are designed for industrial applications, there are a few primary differences which are shown in the table below:Other features, such as pressure-hold or pressure-release deadmans, accessory packages, etc. are available on either series. The economy Classic blast pot with the FSV (flat sand valve) is the best-selling Clemco blast machine. The Contractor series offers more time saving and protection features. This Clemco Blast Machine group includes the 4 and 6 cubic foot versions.

Classic Series Contractor Series Controls Pneumatic standard. Electric only by special quote. Pneumatic or Electric Control Valves Separate Inlet / Outlet valves. Millennium or Quantum (combination inlet/outlet) Design Highlights Portable w/2 wheels. Improved portability (4 wheels) and protection (built-in tube steel handles around valves). Built-in storage for manuals. Improved access to hose fittings. Nomenclature 2452 Std. 6.0cf 2443 Lo 6.0cf (both 24" dia) 2020 4.0cf (20" diameter) 2024 6.0cf (24" diameter) -

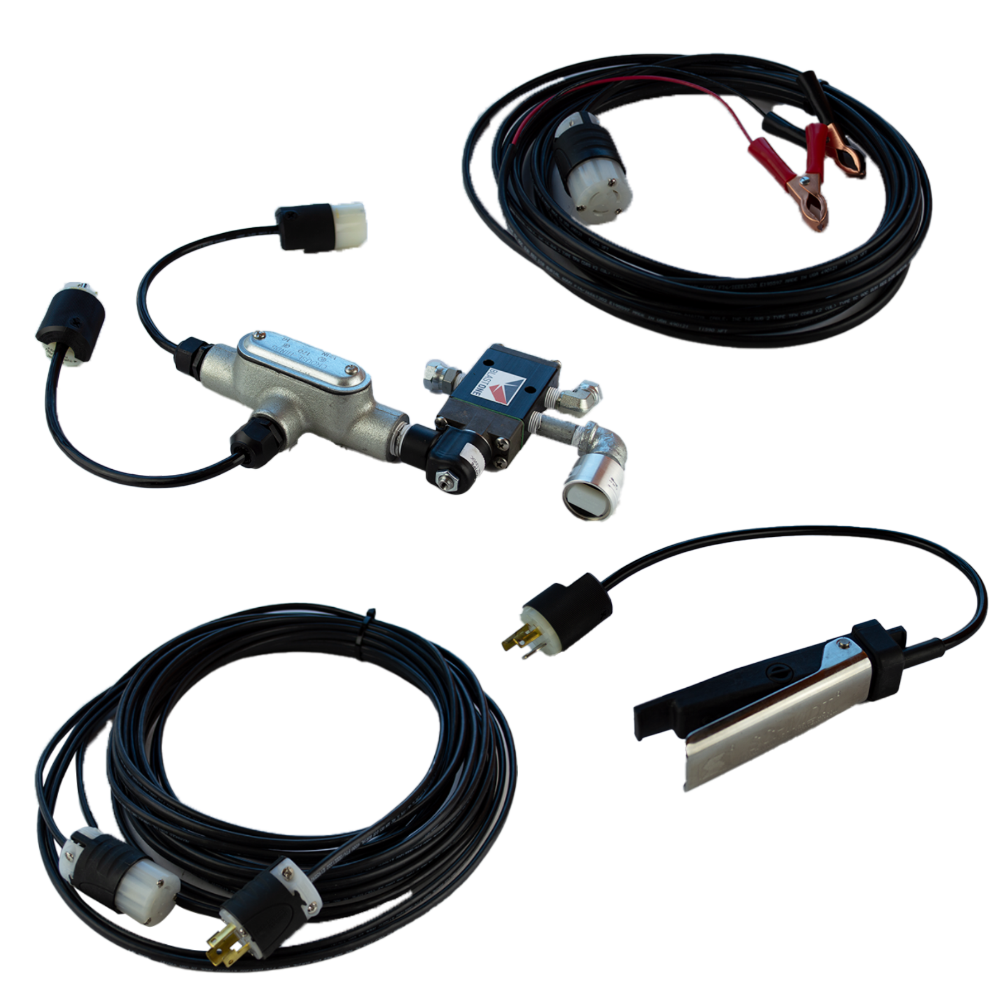

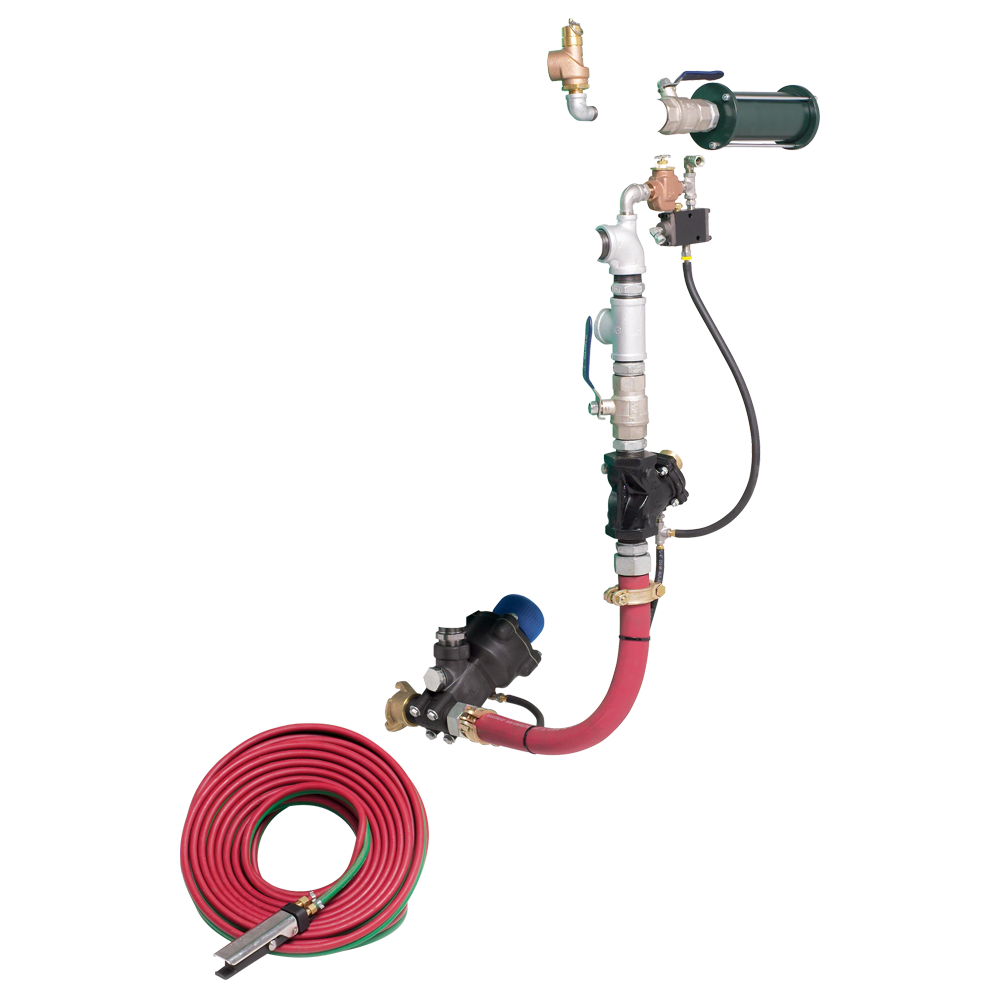

Convert your Pneumatic Blast Pots to 12v Electric Deadman Systems seamlessly with the Pneumatic to Electric Deadman Blast Pot Comprehensive Conversion Kit. Essential for setups with over 100ft of blast hose, electric controls are ideal for anyone who wants fast deadman deactivation. Kit includes connector box, battery cable, and more.

- Pneumatic to Electric Deadman Blast Pot Conversion Kit

- Used to convert Pneumatic Blast Pots over to Electric Deadman Systems

- Electric Deadman should be used on any set ups running over 100ft of blast hose

- Sold as a Conversion Kits including;

- Connector Box

- 16 feet battery cable with alligator clips

- Response G2 electric remote control handle

- 55 foot deadman cable

- TwistLok plug connectors

- Energy consumption rate of 8 watts per control valve

- Assembled by Qualified BlastOne Technicians

-

DM2152ACSThis kit includes all parts needed to change from blasting to blow-off at the flip of a switch at the deadman. Eliminates need for a separate air-hose or trekking back to the pot to shut off the abrasive. This version is for pots with an existing Thompson 2 valve and pneumatic controls.DM2152ACSThis kit includes all parts needed to change from blasting to blow-off at the flip of a switch at the deadman. Eliminates need for a separate air-hose or trekking back to the pot to shut off the abrasive. This version is for pots with an existing Thompson 2 valve and pneumatic controls.

-

DMASAPRK00

- ASAP Safety System Retrofit Kit for 12V DC Thompson® Valve system.

- This System changes the depressurization flow of the air in the blast hose

- Allows a 200ft blast hose to depressurize in less than 1 second

- Changes the depressurization flow to exit backwards through full porting vs having to exit out of the blast nozzle

- Saves Seconds - Saves Lives, if a blaster drops a hose every micro-second counts, it takes the energy out of the hose immediately.

- Sold as a complete kit to be added on to an Electric Controlled Thompson® Valve Blast Pot

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

DMASAPRK00- ASAP Safety System Retrofit Kit for 12V DC Thompson® Valve system.

- This System changes the depressurization flow of the air in the blast hose

- Allows a 200ft blast hose to depressurize in less than 1 second

- Changes the depressurization flow to exit backwards through full porting vs having to exit out of the blast nozzle

- Saves Seconds - Saves Lives, if a blaster drops a hose every micro-second counts, it takes the energy out of the hose immediately.

- Sold as a complete kit to be added on to an Electric Controlled Thompson® Valve Blast Pot

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

-

Enhance the performance of your Axxiom/Schmidt blast pot with high-quality lids and screens designed to protect your abrasive media from debris and moisture contamination. Available individually or in convenient sets, these durable accessories are offered in multiple sizes to fit your blast machine.

- Compatible with Axxiom/Schmidt blast machines as well as other brands with standard 12", 18", 24", and 36" diameters

- 1/4" mesh screen prevents large debris from entering the pot

- Lid helps shield media from moisture, rain, and site contaminants

- Available in individual components or bundled as a lid & screen set

- Color options: White, Black, or BlastOne Orange

-

DM201150190

- Industrial-Grade Muffler for Pressure-Release Blast Pots

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approx. 110 dB.

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Attaches to Combo Valve)

- Any required fittings

- Does not include a new Blow Down hose

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Note: This muffler comes standard on Schmidt combo-micro blast pots from BlastOne.

- Also available for Pressure-Hold systems here

DM201150190- Industrial-Grade Muffler for Pressure-Release Blast Pots

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approx. 110 dB.

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Attaches to Combo Valve)

- Any required fittings

- Does not include a new Blow Down hose

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Note: This muffler comes standard on Schmidt combo-micro blast pots from BlastOne.

- Also available for Pressure-Hold systems here

-

DM201150191

- Industrial-Grade Muffler for Manual Blow-Down (Pressure-hold) Blast Pots with Thompson valve or TeraValve

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approximately 110 dB

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Goes on blast pot leg)

- Blowdown Hose Assembly

- Ball Valve and required fittings

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Also available for Pressure-Release pots here

DM201150191- Industrial-Grade Muffler for Manual Blow-Down (Pressure-hold) Blast Pots with Thompson valve or TeraValve

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approximately 110 dB

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Goes on blast pot leg)

- Blowdown Hose Assembly

- Ball Valve and required fittings

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Also available for Pressure-Release pots here

-

Clemco Industries is the world's largest manufacturer of air-powered blasting equipment. It is over 80 years old, being founded in 1941. The Classic line from Clemco is the original design and offers the largest size selection. This section includes the highly portable 3 cubic foot 1648 series. Similar to the 6 CF Clemco Classic Blast Machines, these smaller units (16" diameter) offer the following:

- Pneumatic controls with separate inlet & outlet valves (electric controls offered on the Contractor series or by special quote only)

- Choice of pressure-release or pressure hold

- Choice of metering valves including FSV, MQV, AQV, GW

- Pots with controls only, OR packages including accessories such as Apollo 600 respirators, blast hose & nozzles, breathing air system (minus the CO monitor, available separately) and more

-

The Schmidt® AmphiBlast™ Lite 3.5 is a compact, mobile wet/dry abrasive blasting system that delivers precision control, minimal water usage, and high efficiency. Featuring easy mode switching and a dry abrasive tank design, this unit offers cleaner operation and superior performance in both standard blasting and Softwash™ applications. Available Options:

- Models with or without the onboard 15 gallon water tank

- Electric or Pneumatic controls - both with the latest G3 Trigger deadman

- Standard abrasives only, or with Multi-Media technology, allowing the use of all medias regardless of weight, including soda

-

Clemco Industries is the world's largest manufacturer of air-powered blasting equipment. It is over 80 years old, being founded in 1941. The Classic line from Clemco is the original design and offers the largest size selection. Excellent for small blasting projects where portability is key, this section includes the 0.5CF (1028 series) and 1.0CF (1042 series). Similar to their larger sisters, these 10" diameter smaller units offer many of the same features including:

- Pneumatic controls with separate inlet & outlet valves, but with ½" piping instead of 1-¼".

- The compact ½" Manual Sand Valve (MSV) - similar to the FSV but specially designed for these smaller units. Note: This valve is designed for expendable mineral and slag abrasives, and is not suited for fine mesh or glass abrasives.

- Pots with TLR-50 controls only, OR full packages including accessories such as the Apollo 20 DLX w/constant flow respirator, 25' blast hose & #4 nozzle, breathing air system (minus the CO monitor, available separately), drop-in screen and more.

- Note: These pots are offered in pressure-release only.

-

The Schmidt® M-Series Multi-Media Blasters are built for pros who need one blast pot that handles it all. From light cleaning with soda to aggressive steel grit work, this series delivers full control, rugged performance, and reliable media flow—job after job.

- Blasts a wide range of abrasives: soda, grit, plastic, glass, and more

- Available with choice of the tried-and-true Thompson II or the latest TeraValve XL, for the ultimate in precision abrasive metering. Both come with a slotted tungsten carbide sleeve.

- G3 Trigger Deadman now standard across all models with the compact BAABS also included in all except the Mini M-Series.

- Pressure and tank regulators dial in your blast profile for each job. Blasting pressure can be set from 10 to 150 PSI.

- Media vibrator boosts flow performance for lighter abrasives

- Quick-detach valve and media shutoff for simplified service

- Available sizes: Mini M-Series (0.9 cu ft), M-11 (1.5 cu ft), M-21 (2.0 cu ft), M-31 (3.0 cu ft)

-

OEM Clemco blast machine lids and screens are useful accessories for many applications. Lids keep the pots from collecting debris - especially when used outdoors. Screens are highly recommended for preventing foreign matter out of the pot when refilling abrasive. They are standard with most new Clemco blast machine packages, but lids are optional. Both are available here in sizes to match any size blast pot from 0.5CF (10") to 20 CF (36").

Why Choose BlastOne’s Blast Equipment?

BlastOne’s blast equipment stands out for its reliability and innovation. Features like ergonomic designs, efficient media usage, and compatibility with various abrasives make our equipment a preferred choice. Our products are backed by expert support and comprehensive training resources, ensuring you get the most out of your investment.

Stay ahead in your projects with equipment that meets stringent industry standards and adapts to evolving needs. Trust BlastOne for solutions that enhance productivity and deliver consistent results.

My Account

My Account

Small Blast Pots

Small Blast Pots Contractor Blast Pots

Contractor Blast Pots Specialty Blast Pots

Specialty Blast Pots MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Mega Bulk Blasters

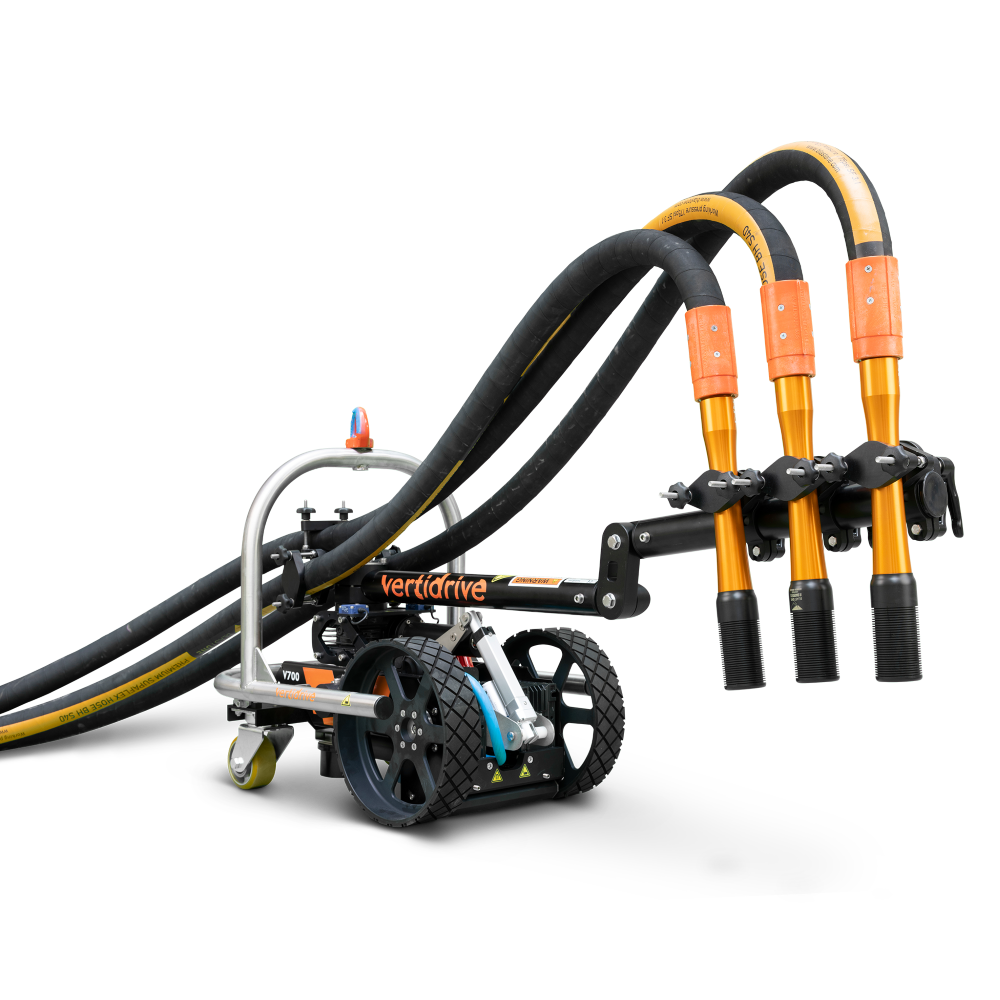

Mega Bulk Blasters Robotic / Vertidrive Equipment

Robotic / Vertidrive Equipment Track Blasters

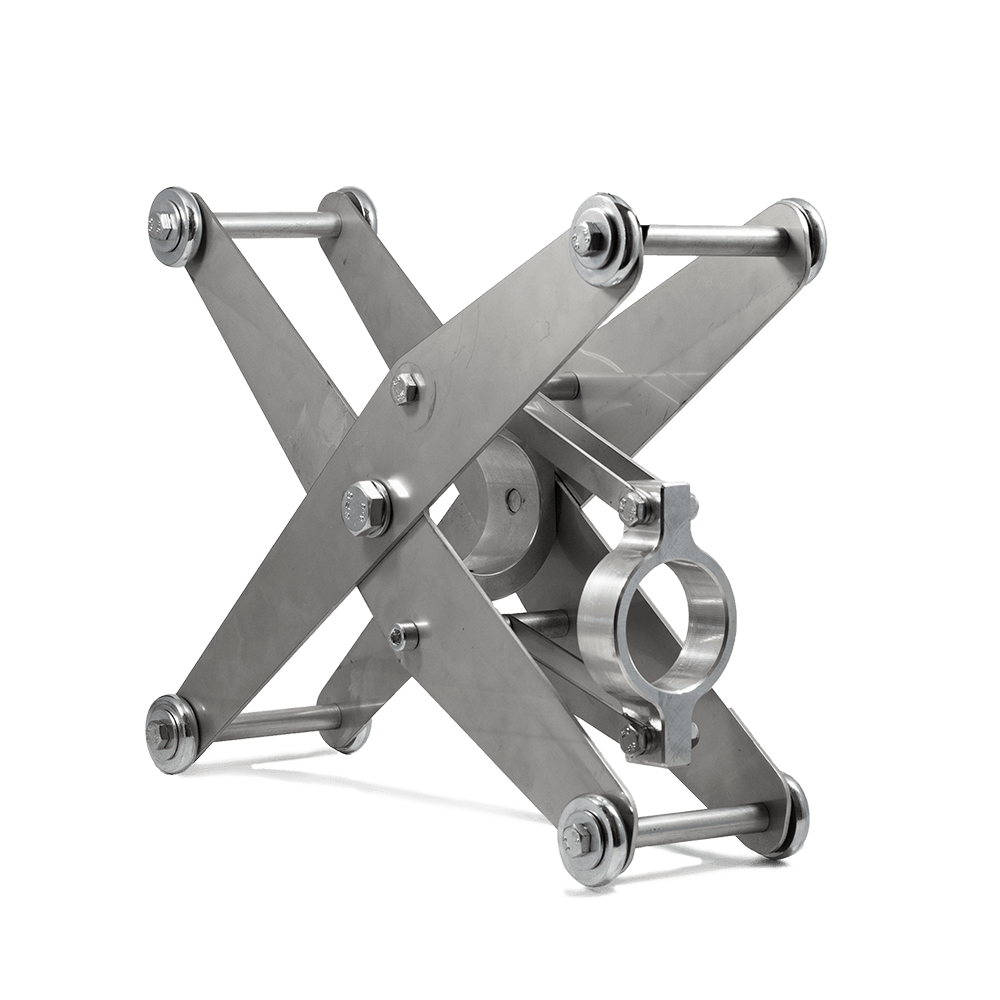

Track Blasters Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Blast Machine Accessories

Blast Machine Accessories