Blast Equipment

Showing 16–30 of 84 results

-

MB60160Boost profits and reduce frustration by converting your EcoQuip® blasting rig to MistBlaster® technology.

- Boost profits by:

- Increased production speed

- Reduced wasted abrasive and rust inhibitor

- Less water usage, reduced cleanup time

- Winning more projects because dry blasting is easy too!

- Reduce frustrations by:

- No need to drain the tank at end of day

- Allows adjustment of water / abrasive ratio

MB60160Boost profits and reduce frustration by converting your EcoQuip® blasting rig to MistBlaster® technology.- Boost profits by:

- Increased production speed

- Reduced wasted abrasive and rust inhibitor

- Less water usage, reduced cleanup time

- Winning more projects because dry blasting is easy too!

- Reduce frustrations by:

- No need to drain the tank at end of day

- Allows adjustment of water / abrasive ratio

- Boost profits by:

-

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

-

The Schmidt® AmphiBlast™ is a versatile, dual-purpose abrasive blasting system designed for efficient wet and dry blasting. Featuring a patent-pending water injection system and Schmidt® Thompson® Valve II, it offers precise control of air, abrasive, and water flows for maximum productivity and minimal material waste. Available in single and dual outlet configurations, all with fork-pocket skid mounts. Key Features:

- Switch between wet blast, dry blast, Softwash™, and blowoff effortlessly.

- Precise water injection for optimal blasting performance and minimal water use

- Supports a wide range of abrasives (coarse and fine)

- High and low-pressure blasting capabilities

- Set and Forget mode switching for consistent performance

- Improved lid construction and quieter blowdown system

- Size Options:

- 1-Outlet, 4.5 cu. ft. Blast Pot | 80-Gallon Water Tank

- 2-Outlet, 6.5 cu. ft. Blast Pot | 165-Gallon Water Tank

- Controls Choices:

- Pneumatic w/Compact BAABS G3 Trigger Deadman

- 12v Electric w/Compact BAABS G3 Trigger Deadman

- Abrasive Cut-Off (ACO) available on 2-outlet 12v Electric

- (The BAABS is the innovative ergonomic system by Schmidt that pairs perfectly with the G3 deadman)

-

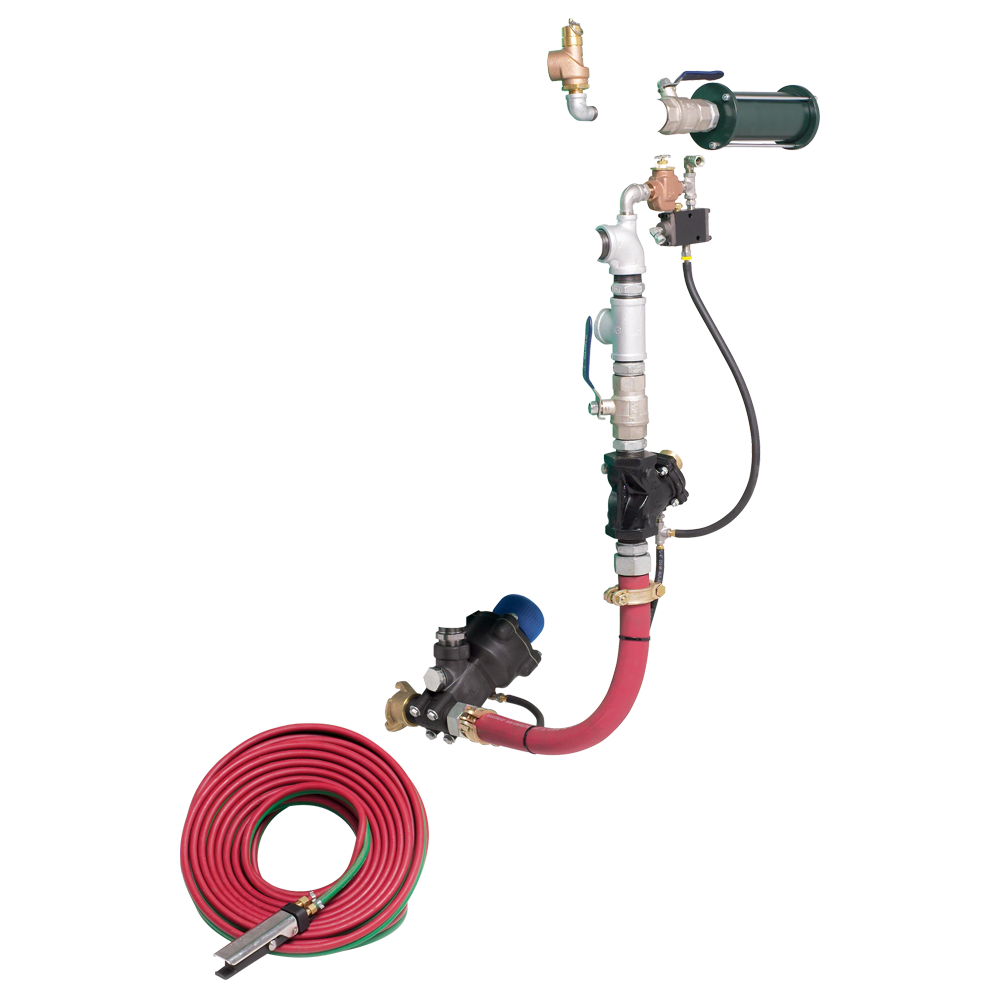

The Clemco Wetblast FLEX™ System is a versatile wet and dry blasting solution, designed for maximum flexibility and productivity. Whether you're blasting in dust-sensitive urban areas or open environments requiring dry blasting, the FLEX system adapts to any job, helping you stay compliant, efficient, and profitable. Key Features:

- Switch between wet and dry blasting with ease

- High-performance water injection system for optimal dust suppression

- Precise water adjustment controls for customizable blasting

- 120-gallon water storage tank with pump included for flexible water sourcing

- Easy-to-use controls for quick setup and operation

- Available in Base Unit and Flex Package configurations

-

The Clemco Pro-Series Big Clem Abrasive Bulk Blasters are engineered for maximum productivity, faster refills, and superior safety. With 175-PSI rated pressure vessels, the fastest refill cycles, and the versatile GritWizard abrasive metering valve, these bulk blasters are designed to handle all common media and streamline operations for efficient, high-volume blasting. Key Features:

- 175-PSI rated pressure vessels – Highest in the industry

- 20% faster refill cycle – Maximizes uptime and productivity

- GritWizard metering valve – Handles all common media with precision control

- Optimized plumbing for maximum pressure delivery

- Improved Super Sack System – Faster, safer abrasive refills

- Pop-up valves – Industry-standard safety for pressure sealing

- Enhanced safety features – Noise-reducing outlet muffler, ergonomic controls, and secure lifting points

-

The Schmidt AmphiBlast™ Mini 1.5 cu. ft. Blast Pot is the most compact and portable wet/dry blasting system in the AmphiBlast family. Designed for high productivity and efficiency, this lightweight unit allows for precise control over air, abrasive, and water flow, minimizing waste and maximizing performance. Available in electric and pneumatic modes, with optional onboard water tank. Key Features:

- Seamlessly switch between wet blast, dry blast, blowoff, and Softwash™

- Minimal water use (less than 1 pint / ½ liter per minute)

- Compact design fits through a 24” doorway (even with onboard tank)

- Schmidt Tera Valve™ XL metering valve for precise abrasive control

- Electric water pump provides high-flow washdown capabilities

- Wide pressure range (10–150 psi) for either delicate or aggressive blasting

-

SBMGI

- High quality, acoustically insulated steel sandwich panel construction

- Ideal for consistent blasting production (1 operator, 20-40 hrs/week)

- Various material handling options: product carts, forklift loading, manual handling

- Partial or Full-floor abrasive recovery system

- Airwash abrasive cleaner for grit recycling with vibrating screen for trash removal

- Reverse pulse cartridge dust collector

- Typical size ranging from:

- 10’ W x 10’ H x 10’ L (small)

- 22’ W x 22’ H x 100’ L (large)

SBMGI- High quality, acoustically insulated steel sandwich panel construction

- Ideal for consistent blasting production (1 operator, 20-40 hrs/week)

- Various material handling options: product carts, forklift loading, manual handling

- Partial or Full-floor abrasive recovery system

- Airwash abrasive cleaner for grit recycling with vibrating screen for trash removal

- Reverse pulse cartridge dust collector

- Typical size ranging from:

- 10’ W x 10’ H x 10’ L (small)

- 22’ W x 22’ H x 100’ L (large)

-

- Robots made by Blastman Robotics specifically for Blastroom applications

- Available as 4-Axis, 7-Axis or 8-Axis.

- Available as Wall Mount or Gantry Mount

- Optional Man cabin for manual blasting which can come mounted on the blasting arm, or as a separate cabin

- 20+ years of installation and robotic experience

- Read here for more pictures of Blastman Blasting Robots

-

SBMGP

- Pre-engineered to minimize costs and ensure quick set up

- Typical max part size (to be blasted): 5’ x 3’ x 8’ (W x H x L)

- Blasting chamber with set of double-doors

- Dust tight, high-powered LED lights in ceiling

- Shovel-in hopper, elevator and air classifier for basic abrasive recovery/recycling

- Includes abrasive storage hopper and high-performance sandblasting machine

- Separate personnel side access door (optional)

SBMGP- Pre-engineered to minimize costs and ensure quick set up

- Typical max part size (to be blasted): 5’ x 3’ x 8’ (W x H x L)

- Blasting chamber with set of double-doors

- Dust tight, high-powered LED lights in ceiling

- Shovel-in hopper, elevator and air classifier for basic abrasive recovery/recycling

- Includes abrasive storage hopper and high-performance sandblasting machine

- Separate personnel side access door (optional)

-

SBMGE

- Modified High-cube-style shipping container construction (20 ft, 40 ft)

- Watertight, Weatherproof design

- Completely self-contained for maximum portability

- Simple setup/installation

- Partial abrasive recovery system, with shovel-in hopper

- Available as fully assembled unit or retrofit kit

- Instant Preliminary Quotes Available on Request!

SBMGE- Modified High-cube-style shipping container construction (20 ft, 40 ft)

- Watertight, Weatherproof design

- Completely self-contained for maximum portability

- Simple setup/installation

- Partial abrasive recovery system, with shovel-in hopper

- Available as fully assembled unit or retrofit kit

- Instant Preliminary Quotes Available on Request!

-

SBMGZ

- Custom designed blasting and painting facilities, sized as large as application requires

- Ideal for new construction and repair, for vessels of all type and size

- Available configurations:

- Hybrid blast/paint hall - single hall for both operations at different times

- 2 separate halls - each single-purpose hall dedicated to blasting or painting

- Available with completely controllable environmental conditions to meet required specifications

- Compatible with abrasive recovery and recycling equipment with many available configurations

SBMGZ- Custom designed blasting and painting facilities, sized as large as application requires

- Ideal for new construction and repair, for vessels of all type and size

- Available configurations:

- Hybrid blast/paint hall - single hall for both operations at different times

- 2 separate halls - each single-purpose hall dedicated to blasting or painting

- Available with completely controllable environmental conditions to meet required specifications

- Compatible with abrasive recovery and recycling equipment with many available configurations

-

SBMGWThese blast rooms are designed to improve flow in a Wind Tower manufacturing facility, and can be made to handle both internal and exterior blast, with nearly any level of automation.SBMGWThese blast rooms are designed to improve flow in a Wind Tower manufacturing facility, and can be made to handle both internal and exterior blast, with nearly any level of automation.

-

Large Fabric Lift-Up Doors are a high-performance solution designed for blast and paint booths, especially in demanding shipyard environments. These durable and space-efficient doors provide superior sealing, weather resistance, and customizable dimensions to handle the largest ship components. They ensure operational efficiency and controlled environments for industrial applications.

Key Features:

- Vertical lift design maximizes floor and wall space for efficient operations.

- Heavy-duty fabric construction reinforced with steel frames for durability.

- Customizable dimensions for seamless access to large-scale projects.

- Superior sealing to maintain controlled environments for blasting or painting.

- Weather-resistant and designed to withstand harsh industrial conditions.

- Equipped with safety systems, high-speed motors, and precision controls.

-

Clemco Industries is the world's largest manufacturer of air-powered blasting equipment. It is over 80 years old, being founded in 1941. Clemco offers two series of blast machines - the Classic and the Contractor Pots. While both are designed for industrial applications, there are a few primary differences which are shown in the table below:Other features, such as pressure-hold or pressure-release deadmans, accessory packages, etc. are available on either series. The economy Classic blast pot with the FSV (flat sand valve) is the best-selling Clemco blast machine. The Contractor series offers more time saving and protection features. This Clemco Blast Machine group includes the 4 and 6 cubic foot versions.

Classic Series Contractor Series Controls Pneumatic standard. Electric only by special quote. Pneumatic or Electric Control Valves Separate Inlet / Outlet valves. Millennium or Quantum (combination inlet/outlet) Design Highlights Portable w/2 wheels. Improved portability (4 wheels) and protection (built-in tube steel handles around valves). Built-in storage for manuals. Improved access to hose fittings. Nomenclature 2452 Std. 6.0cf 2443 Lo 6.0cf (both 24" dia) 2020 4.0cf (20" diameter) 2024 6.0cf (24" diameter) -

Convert your Pneumatic Blast Pots to 12v Electric Deadman Systems seamlessly with the Pneumatic to Electric Deadman Blast Pot Comprehensive Conversion Kit. Essential for setups with over 100ft of blast hose, electric controls are ideal for anyone who wants fast deadman deactivation. Kit includes connector box, battery cable, and more.

- Pneumatic to Electric Deadman Blast Pot Conversion Kit

- Used to convert Pneumatic Blast Pots over to Electric Deadman Systems

- Electric Deadman should be used on any set ups running over 100ft of blast hose

- Sold as a Conversion Kits including;

- Connector Box

- 16 feet battery cable with alligator clips

- Response G2 electric remote control handle

- 55 foot deadman cable

- TwistLok plug connectors

- Energy consumption rate of 8 watts per control valve

- Assembled by Qualified BlastOne Technicians

Why Choose BlastOne’s Blast Equipment?

BlastOne’s blast equipment stands out for its reliability and innovation. Features like ergonomic designs, efficient media usage, and compatibility with various abrasives make our equipment a preferred choice. Our products are backed by expert support and comprehensive training resources, ensuring you get the most out of your investment.

Stay ahead in your projects with equipment that meets stringent industry standards and adapts to evolving needs. Trust BlastOne for solutions that enhance productivity and deliver consistent results.

My Account

My Account

Small Blast Pots

Small Blast Pots Contractor Blast Pots

Contractor Blast Pots Specialty Blast Pots

Specialty Blast Pots MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Mega Bulk Blasters

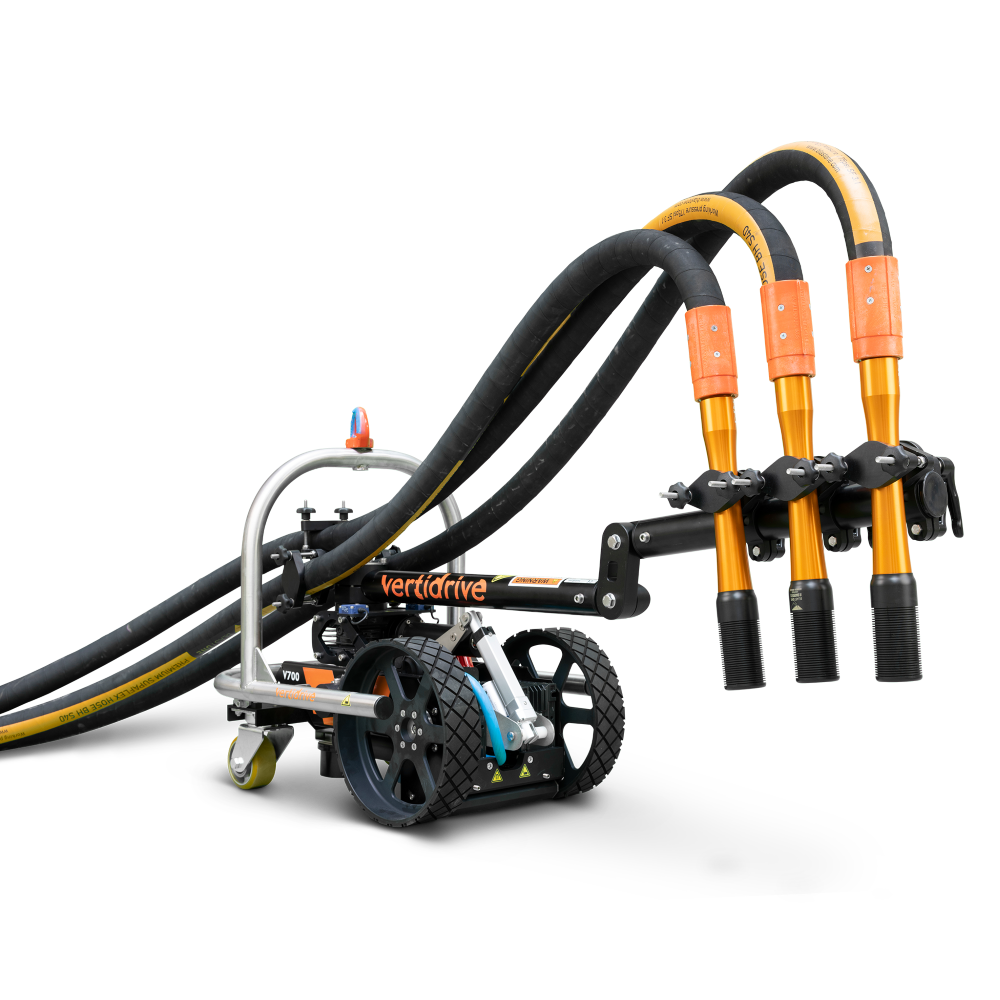

Mega Bulk Blasters Robotic / Vertidrive Equipment

Robotic / Vertidrive Equipment Track Blasters

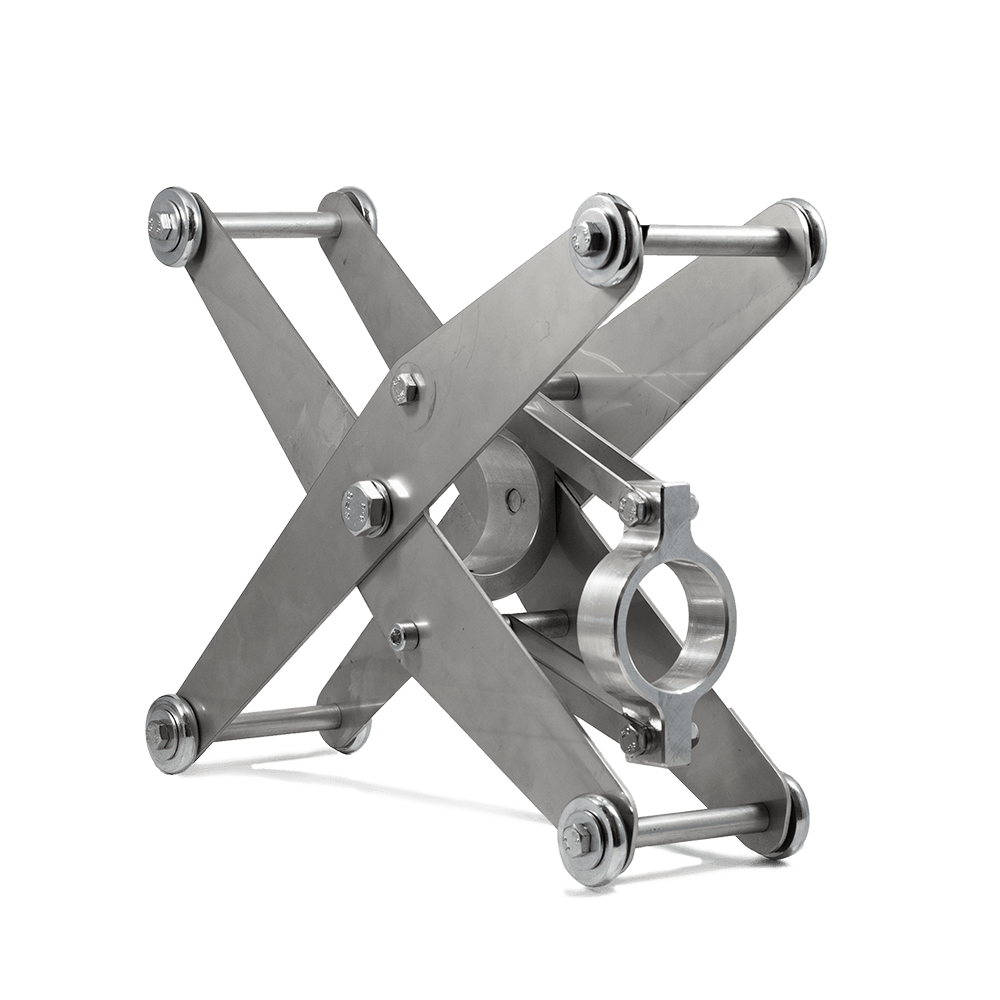

Track Blasters Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Blast Machine Accessories

Blast Machine Accessories