Internal Pipe (ID) Systems

Our internal pipe (ID) systems are engineered for superior performance in demanding industrial environments. With options for automated and manual operation, these tools ensure comprehensive internal pipe cleaning and preparation. From robust robotic systems capable of handling large pipelines to versatile centering carriages for different pipe sizes, our products are designed to enhance efficiency and reduce labor costs.

For specialized assistance or to find the exact tool for your needs, contact BlastOne or use the live chat feature in the bottom right of your browser window.

Showing all 12 results

-

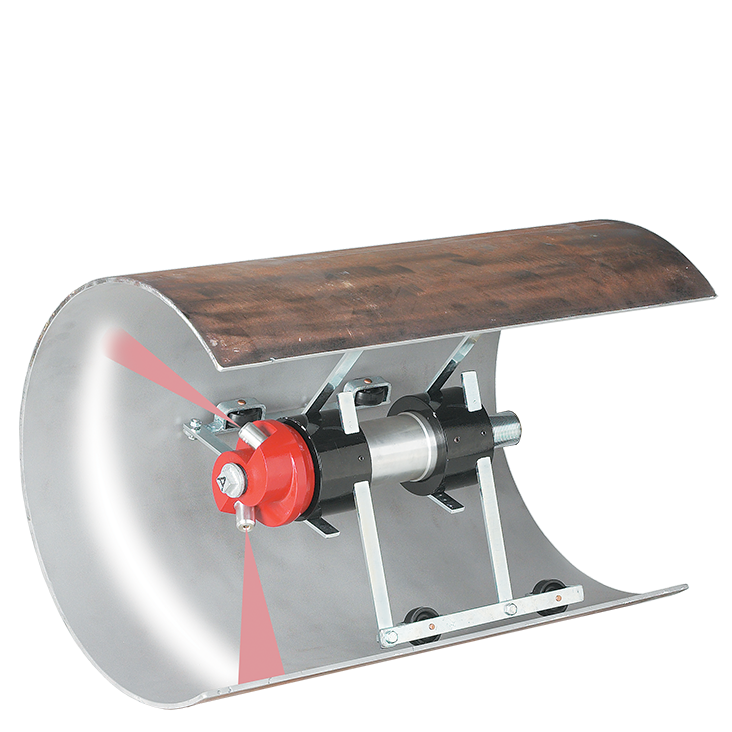

IPC1000The RotorBlast is the fastest way to blast the internals of pipes. This IPC1000 version is designed for pipes from 10" to 35" ID. Fast and effective blasting is ensured by the twin-nozzle spinning blast head. Additional details of this Internal Pipe Blaster are as follows:

- 360 degree blasting covers the entire ID of the pipe

- Speed is manually controlled. Optional electric winch is also available, helping to save labor and aid consistency in results.

- This IPC1000 pipe blasting tool works in pipes 10" to 35" ID

- Nozzles sold separately - details below:

- 2 nozzles are required for this unit.

- Use BNAT nozzles for pipes from 8" to 11" ID.

- Use BNASB nozzles for pipes from 12" to 36" ID.

- Centering carriage sold separately - details below:

- IPC1200 Centering Carriage is required and is adjustable to work in pipes from 8 to 36" in diameter.

- Note: ID blasting equipment requires significant maintenance. A Rotorblast Repair Parts Kit is available for convenience, or individual parts may be purchased under the Parts Tab. An operators manual is shown under the documents tab or you can contact us for further information.

IPC1000The RotorBlast is the fastest way to blast the internals of pipes. This IPC1000 version is designed for pipes from 10" to 35" ID. Fast and effective blasting is ensured by the twin-nozzle spinning blast head. Additional details of this Internal Pipe Blaster are as follows:- 360 degree blasting covers the entire ID of the pipe

- Speed is manually controlled. Optional electric winch is also available, helping to save labor and aid consistency in results.

- This IPC1000 pipe blasting tool works in pipes 10" to 35" ID

- Nozzles sold separately - details below:

- 2 nozzles are required for this unit.

- Use BNAT nozzles for pipes from 8" to 11" ID.

- Use BNASB nozzles for pipes from 12" to 36" ID.

- Centering carriage sold separately - details below:

- IPC1200 Centering Carriage is required and is adjustable to work in pipes from 8 to 36" in diameter.

- Note: ID blasting equipment requires significant maintenance. A Rotorblast Repair Parts Kit is available for convenience, or individual parts may be purchased under the Parts Tab. An operators manual is shown under the documents tab or you can contact us for further information.

-

Clemco offers a wide range of equipment that provides high-efficiency 360-degree cleaning for pipe interiors. Suitable for industrial applications, these tools are capable of providing precise and effective surface preparation. The two Hollo-Blast unit versions function essentially as nozzles, and work by utilizing a deflection tip at the end of the orifice. The tip deflects the abrasive into a 360° pattern. They are designed for pipes ranging from only ¾" - 2" ID (Junior Series) to 2" to 12" ID (standard Hollo-Blast Series). Larger ID pipe can also be done, but with a different series of equipment. Optional centering carriages are also available, adding efficiency and consistency to the blast. Internal Pipe blasting is a specialized process involving high wear on certain components. BlastOne's technical staff is available to assist with your questions.

-

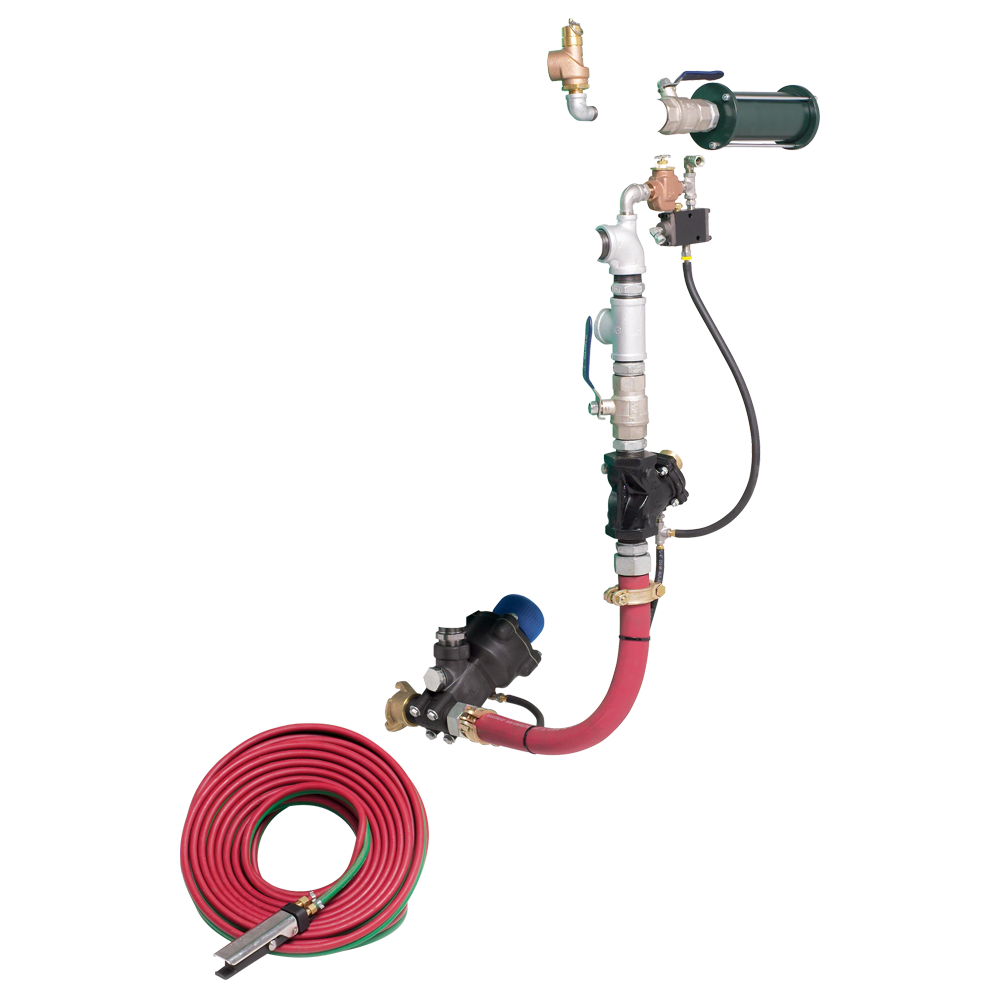

IPC3100

- Easy setup

- Tungsten carbide deflection head and throat nozzle

- For pipes 3/4" to 2" ID

- Includes 'hex collar' centering carriage set

- Requires 120 CFM air supply

- Adapts to customer supplied length of 3/8" threaded lance

- Compatible with standard blast machines

IPC3100- Easy setup

- Tungsten carbide deflection head and throat nozzle

- For pipes 3/4" to 2" ID

- Includes 'hex collar' centering carriage set

- Requires 120 CFM air supply

- Adapts to customer supplied length of 3/8" threaded lance

- Compatible with standard blast machines

-

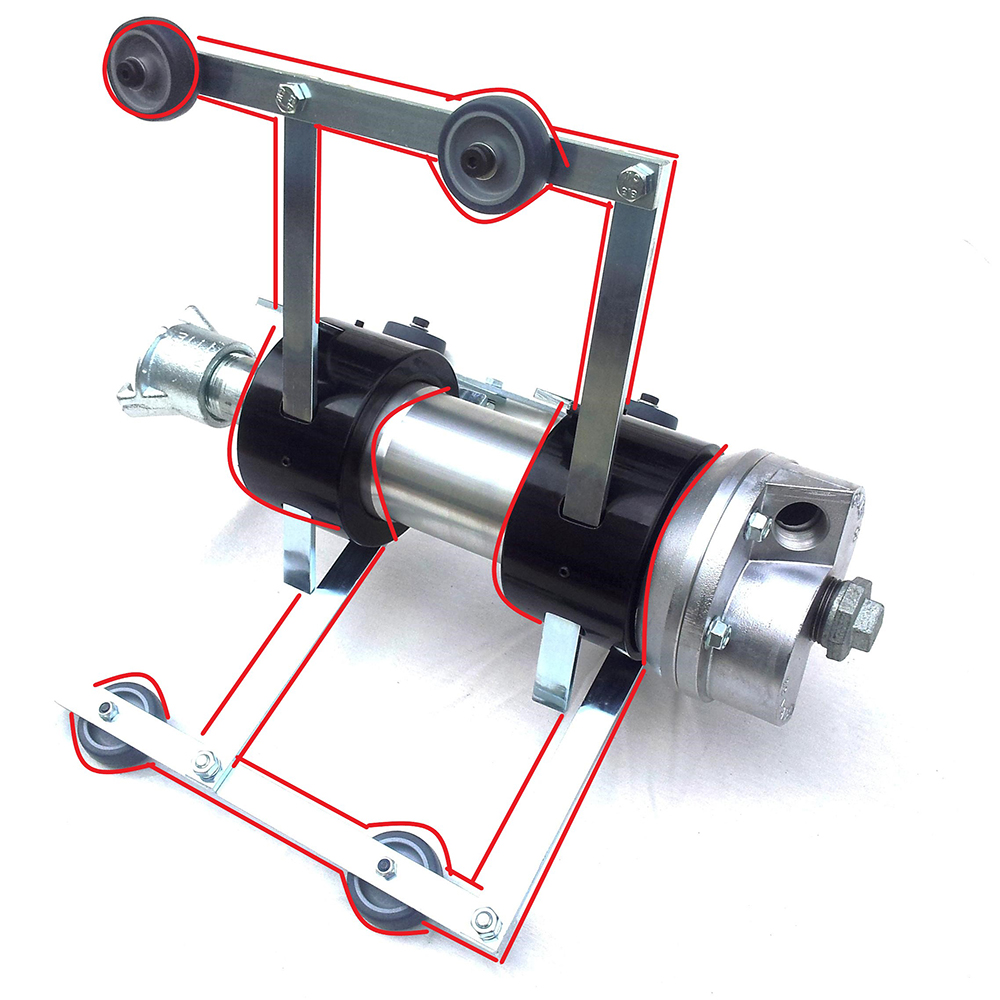

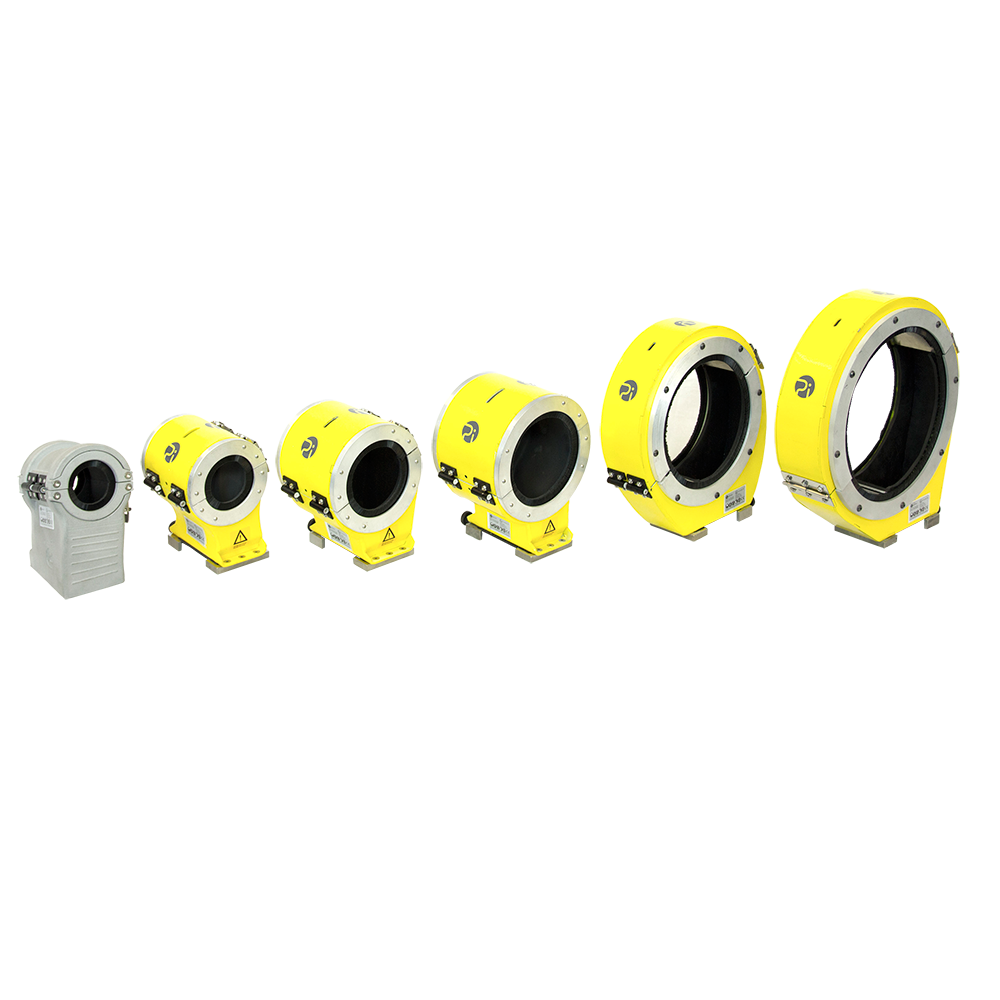

IPC1200

- Fits to IPC1000 as one assembly (outlined in red in image)

- Suitable for pipes between 10" and 35" in diameter

- Consists of 2 collars, 3 two-wheel roller bars and 4 sets of centering legs (6 legs per set)

IPC1200- Fits to IPC1000 as one assembly (outlined in red in image)

- Suitable for pipes between 10" and 35" in diameter

- Consists of 2 collars, 3 two-wheel roller bars and 4 sets of centering legs (6 legs per set)

-

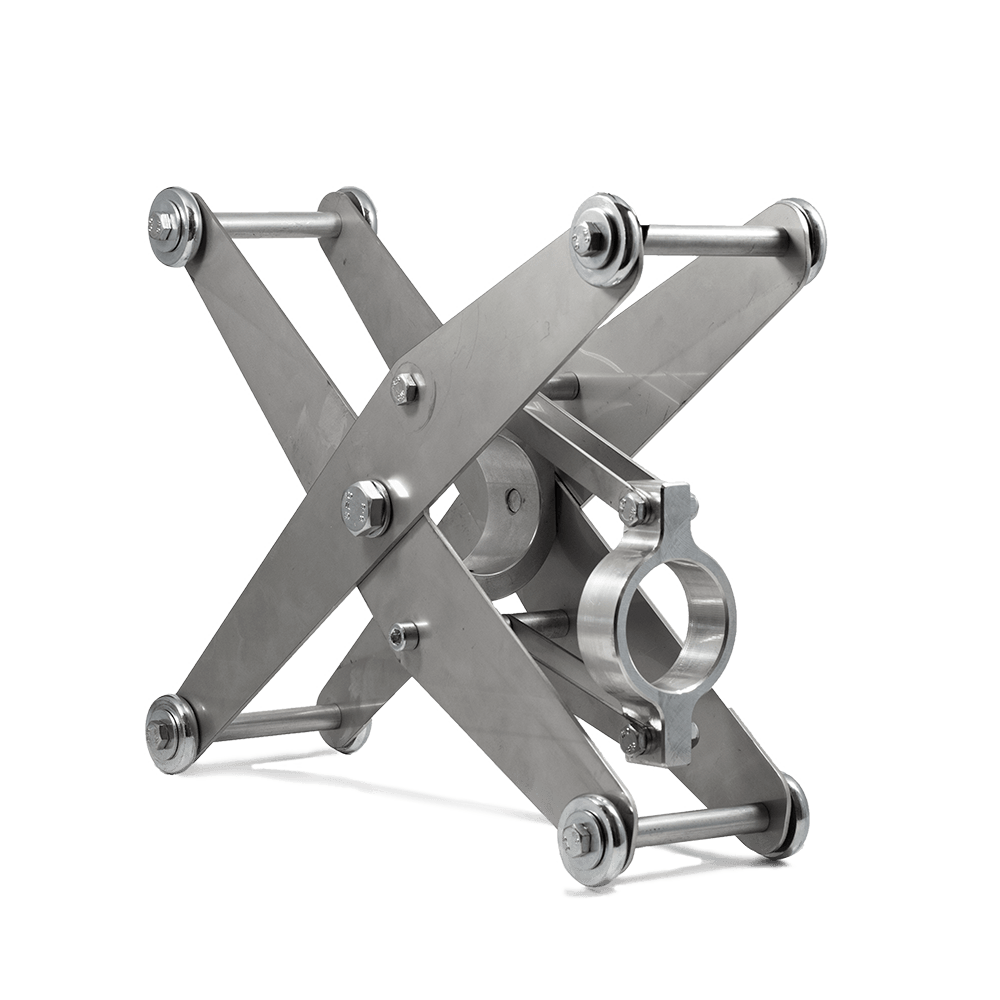

IPC4200

- Suits IPC4000 and IPC4500 ConeBlast Pipe Blasting System

- Ideal for blasting pipes between 5'' - 12'' internal diameter

- 'Scissor Type' Centering Carriage

- Sold Individually

IPC4200- Suits IPC4000 and IPC4500 ConeBlast Pipe Blasting System

- Ideal for blasting pipes between 5'' - 12'' internal diameter

- 'Scissor Type' Centering Carriage

- Sold Individually

-

BNATC360BOLT

- Replacement bolt for the Internal Pipe 360° Blast Nozzle

- Sold - individually

BNATC360BOLT- Replacement bolt for the Internal Pipe 360° Blast Nozzle

- Sold - individually

-

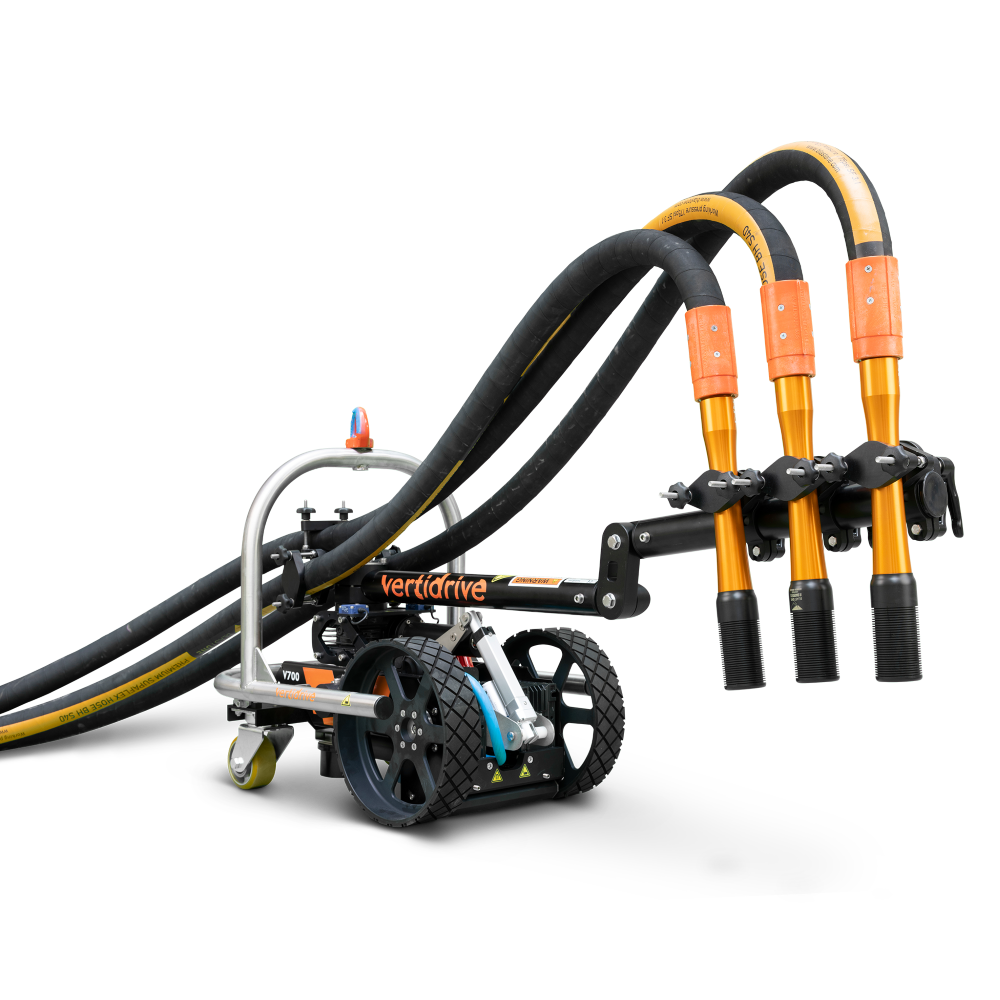

IPRIPTBFOR RENTAL OR PURCHASE

- Ideal for blasting penstocks, tunnels, pipelines, wind towers, etc.

- Offers full 360 degree coverage of pipe internals

- Self-propelled forward or reverse motion

- Can blast pipelines 3' - 32' in diameter

- Lowers labor costs as much as 75% compared with manual blast-pot operations

- Eliminates inconsistencies commonly found with manual blasting

IPRIPTBFOR RENTAL OR PURCHASE- Ideal for blasting penstocks, tunnels, pipelines, wind towers, etc.

- Offers full 360 degree coverage of pipe internals

- Self-propelled forward or reverse motion

- Can blast pipelines 3' - 32' in diameter

- Lowers labor costs as much as 75% compared with manual blast-pot operations

- Eliminates inconsistencies commonly found with manual blasting

-

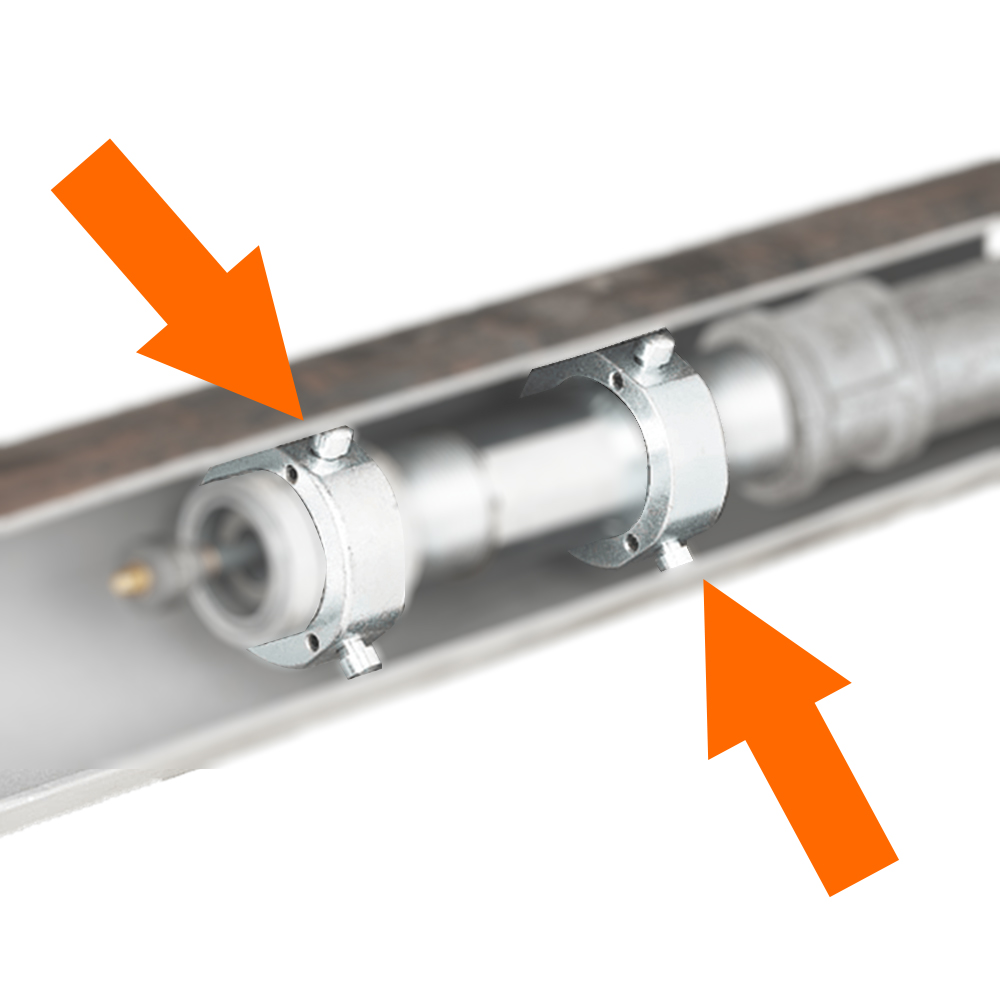

BAWH10110V

- Designed for use with the rotorblast and cone blasters when ID blasting

- Semi-automatically feeds the blast hose at a consistent rate through the pipe being blasted

- Ensures a consistent blast pattern vs manual handling of the hose

BAWH10110V- Designed for use with the rotorblast and cone blasters when ID blasting

- Semi-automatically feeds the blast hose at a consistent rate through the pipe being blasted

- Ensures a consistent blast pattern vs manual handling of the hose

Internal pipe (ID) systems are specialized tools designed to efficiently blast the interiors of pipes, ensuring thorough cleaning and preparation for further treatments. Our selection includes a variety of innovative solutions such as blast hose winches, centering carriages, and advanced robotic systems. These tools provide full 360-degree coverage, enabling consistent and effective blasting performance. Ideal for various pipe diameters, our internal pipe systems are essential for industries requiring precise and reliable internal pipe cleaning. Whether you need automated systems or manual tools, we offer the right equipment to meet your specific requirements.

My Account

My Account

Small Blast Pots

Small Blast Pots Contractor Blast Pots

Contractor Blast Pots Specialty Blast Pots

Specialty Blast Pots MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Mega Bulk Blasters

Mega Bulk Blasters Robotic / Vertidrive Equipment

Robotic / Vertidrive Equipment Track Blasters

Track Blasters Blast Machine Accessories

Blast Machine Accessories