Blast Machine Accessories

Our blast machine accessories are built to support the demanding requirements of industrial blasting. Featuring high-quality components from trusted manufacturers like Schmidt® and Axxiom Manufacturing, these accessories ensure durability and reliability. Products such as the CEN Muffler Retrofit Kit and the Schmidt BAABS Trigger Rail Deadman System provide enhanced safety and ease of use. For specialized needs like water supply pumps and timer pressure switches, our selection offers versatile solutions to keep your blasting operations running efficiently.

If you need personalized assistance or can’t find a specific accessory, contact BlastOne or use the live chat feature in the bottom right of your browser window.

Showing all 15 results

-

Convert your Pneumatic Blast Pots to 12v Electric Deadman Systems seamlessly with the Pneumatic to Electric Deadman Blast Pot Comprehensive Conversion Kit. Essential for setups with over 100ft of blast hose, electric controls are ideal for anyone who wants fast deadman deactivation. Kit includes connector box, battery cable, and more.

- Pneumatic to Electric Deadman Blast Pot Conversion Kit

- Used to convert Pneumatic Blast Pots over to Electric Deadman Systems

- Electric Deadman should be used on any set ups running over 100ft of blast hose

- Sold as a Conversion Kits including;

- Connector Box

- 16 feet battery cable with alligator clips

- Response G2 electric remote control handle

- 55 foot deadman cable

- TwistLok plug connectors

- Energy consumption rate of 8 watts per control valve

- Assembled by Qualified BlastOne Technicians

-

DM2152ACSThis kit includes all parts needed to change from blasting to blow-off at the flip of a switch at the deadman. Eliminates need for a separate air-hose or trekking back to the pot to shut off the abrasive. This version is for pots with an existing Thompson 2 valve and pneumatic controls.DM2152ACSThis kit includes all parts needed to change from blasting to blow-off at the flip of a switch at the deadman. Eliminates need for a separate air-hose or trekking back to the pot to shut off the abrasive. This version is for pots with an existing Thompson 2 valve and pneumatic controls.

-

DMASAPRK00

- ASAP Safety System Retrofit Kit for 12V DC Thompson® Valve system.

- This System changes the depressurization flow of the air in the blast hose

- Allows a 200ft blast hose to depressurize in less than 1 second

- Changes the depressurization flow to exit backwards through full porting vs having to exit out of the blast nozzle

- Saves Seconds - Saves Lives, if a blaster drops a hose every micro-second counts, it takes the energy out of the hose immediately.

- Sold as a complete kit to be added on to an Electric Controlled Thompson® Valve Blast Pot

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

DMASAPRK00- ASAP Safety System Retrofit Kit for 12V DC Thompson® Valve system.

- This System changes the depressurization flow of the air in the blast hose

- Allows a 200ft blast hose to depressurize in less than 1 second

- Changes the depressurization flow to exit backwards through full porting vs having to exit out of the blast nozzle

- Saves Seconds - Saves Lives, if a blaster drops a hose every micro-second counts, it takes the energy out of the hose immediately.

- Sold as a complete kit to be added on to an Electric Controlled Thompson® Valve Blast Pot

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

-

Enhance the performance of your Axxiom/Schmidt blast pot with high-quality lids and screens designed to protect your abrasive media from debris and moisture contamination. Available individually or in convenient sets, these durable accessories are offered in multiple sizes to fit your blast machine.

- Compatible with Axxiom/Schmidt blast machines as well as other brands with standard 12", 18", 24", and 36" diameters

- 1/4" mesh screen prevents large debris from entering the pot

- Lid helps shield media from moisture, rain, and site contaminants

- Available in individual components or bundled as a lid & screen set

- Color options: White, Black, or BlastOne Orange

-

DM201150190

- Industrial-Grade Muffler for Pressure-Release Blast Pots

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approx. 110 dB.

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Attaches to Combo Valve)

- Any required fittings

- Does not include a new Blow Down hose

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Note: This muffler comes standard on Schmidt combo-micro blast pots from BlastOne.

- Also available for Pressure-Hold systems here

DM201150190- Industrial-Grade Muffler for Pressure-Release Blast Pots

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approx. 110 dB.

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Attaches to Combo Valve)

- Any required fittings

- Does not include a new Blow Down hose

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Note: This muffler comes standard on Schmidt combo-micro blast pots from BlastOne.

- Also available for Pressure-Hold systems here

-

DM201150191

- Industrial-Grade Muffler for Manual Blow-Down (Pressure-hold) Blast Pots with Thompson valve or TeraValve

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approximately 110 dB

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Goes on blast pot leg)

- Blowdown Hose Assembly

- Ball Valve and required fittings

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Also available for Pressure-Release pots here

DM201150191- Industrial-Grade Muffler for Manual Blow-Down (Pressure-hold) Blast Pots with Thompson valve or TeraValve

- Safer and much longer lasting than 'throw-away' mufflers

- Reduces blow-down noise to approximately 110 dB

- Intercepts abrasive that may otherwise escape when depressurizing

- Sold as a Field-Installable Retrofit Kit including;

- VBS II Exhaust Muffler

- Mounting Bracket (Goes on blast pot leg)

- Blowdown Hose Assembly

- Ball Valve and required fittings

- Genuine Products - Manufactured by Axxiom Manufacturing/Schmidt

- Also available for Pressure-Release pots here

-

OEM Clemco blast machine lids and screens are useful accessories for many applications. Lids keep the pots from collecting debris - especially when used outdoors. Screens are highly recommended for preventing foreign matter out of the pot when refilling abrasive. They are standard with most new Clemco blast machine packages, but lids are optional. Both are available here in sizes to match any size blast pot from 0.5CF (10") to 20 CF (36").

-

-

The latest innovation in deadman safety technology from Axxiom is the BAABS (Blasting Accessories and Assist Bracket System). Intended to be the safest deadman on the market, it mechanically prevents inadvertent activation. The Schmidt BAABS deadman is such a leap forward in safety technology that Axxiom provides them as standard equipment with most new blast pot or valve retrofit purchases.*

All BAABS use the Axxiom G3 trigger deadman configurable as either electric or pneumatic.

All BAABS units are capable of being fitted with the BAABS blast light for improved vision in dim or dusty environments. (Note: When the light is used with the Subcompact BAABS, there is not room for the thrust brace.)

*The standard configuration provided with new equipment is the Compact size. See Product Description tab for all size options.

-

DM2152ACRK

- Pneumatic Complete Retrofit kit includes:

- Triple-line coupled remote control hose

- Control hose connections for air supply

- Auto air valve and Thompson Valve II metering valve

- Pneumatic push-pull abrasive on-off switch

- Response deadman handle

DM2152ACRK- Pneumatic Complete Retrofit kit includes:

- Triple-line coupled remote control hose

- Control hose connections for air supply

- Auto air valve and Thompson Valve II metering valve

- Pneumatic push-pull abrasive on-off switch

- Response deadman handle

-

- Compatible with a wide range of blast pots

- Digital display of actual blasting time for individual blast outlets

- Allows you to determine productivity, production rates, assisting project costings, job estimates and scheduling maintenance for common wear items

- System available to run off pneumatic and electric deadman controls

- Triggered instantly by the deadman signal, so you get actual blasting hours

- Options available for single and multiple outlets.

-

BA871098627

- Suits Blast Pot timer

- Pressure Switch to allow hour counter to count actual blasting hours

- Working PSI range of 10-150 PSI

- Sold Individually

BA871098627- Suits Blast Pot timer

- Pressure Switch to allow hour counter to count actual blasting hours

- Working PSI range of 10-150 PSI

- Sold Individually

-

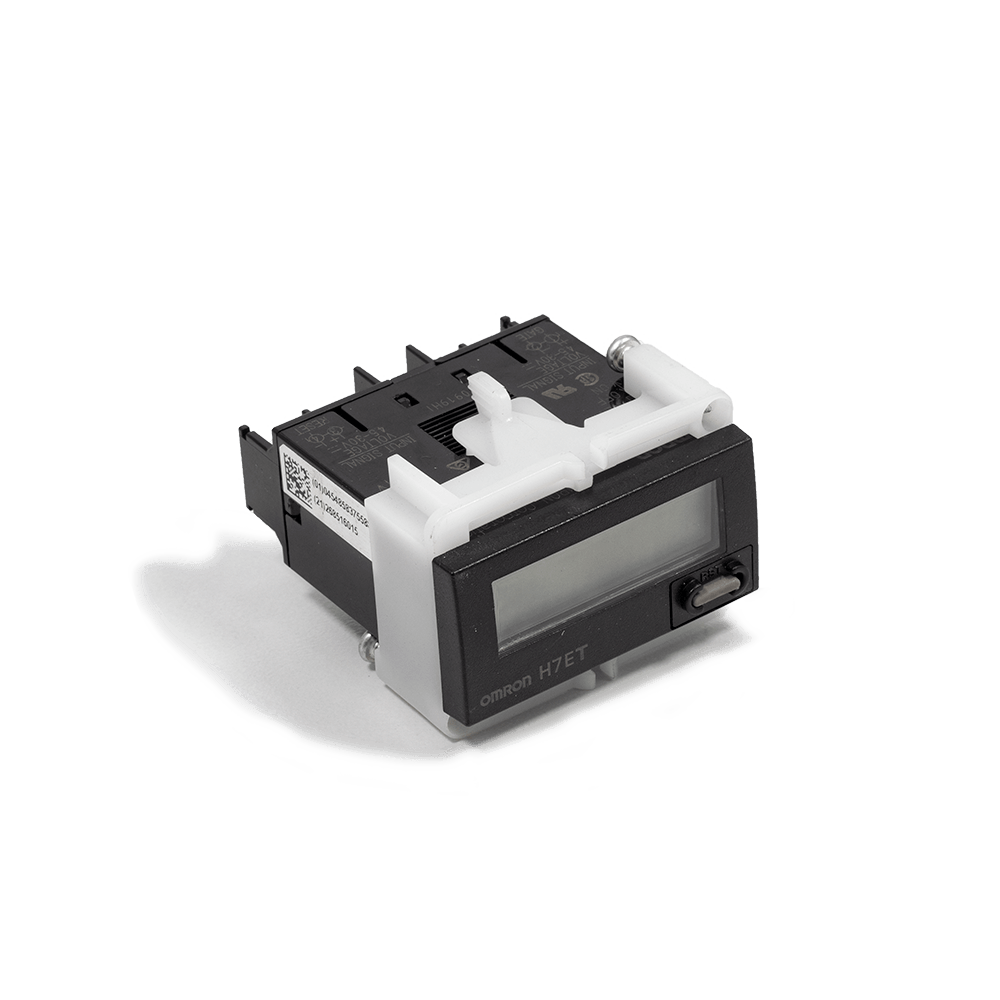

BA7124889

- Suits Blast Pot timer

- Suit No Voltage Applications

- Used to measure actual hours spent blasting

- LCD Timer with Built-In Battery

- Sold Individually

BA7124889- Suits Blast Pot timer

- Suit No Voltage Applications

- Used to measure actual hours spent blasting

- LCD Timer with Built-In Battery

- Sold Individually

-

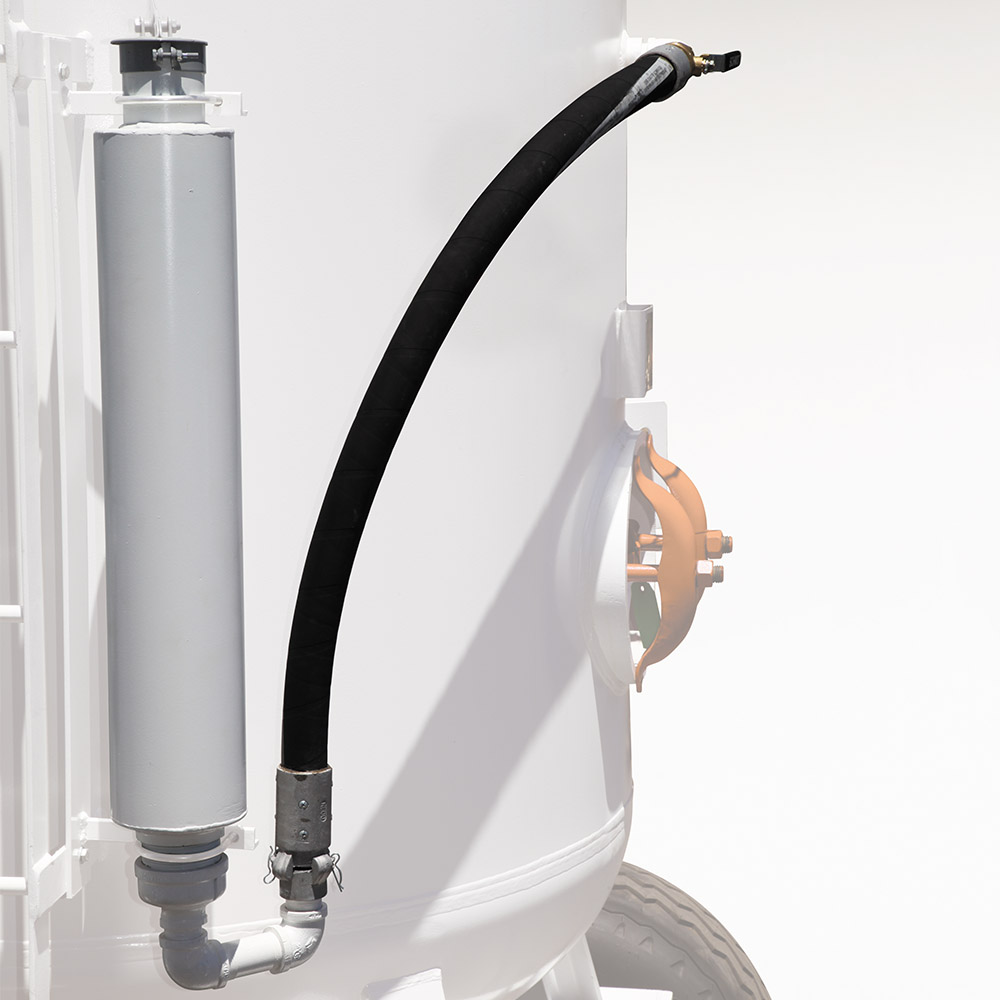

DMMEM100KIT

The Controlled Expansion Nozzle (CEN) Muffler Kit by Axxiom / Schmidt for Mega Pots significantly improves safety as well as reducing blowdown noise.

- Using a CEN muffler removes the risk of freeze-up at the vent. Without this muffler, dangerous pressure can remain in the pot due to vent freeze-up. Injury or death can result to an operator who removes the abrasive loading cover under pressure.

- In addition, noise levels during blowdown without a CEN can exceed 140db. With the CEN, the noise is reduced to 92db.

- The kit includes a 3" NPT thread connection. As mounting brackets are not included in the kit (due to the restriction on welding on a pressure vessel after certification), customer will need to decide best place for mounting, possibly using the ladder. BlastOne technicians are available - contact us if any questions.

DMMEM100KITThe Controlled Expansion Nozzle (CEN) Muffler Kit by Axxiom / Schmidt for Mega Pots significantly improves safety as well as reducing blowdown noise.

- Using a CEN muffler removes the risk of freeze-up at the vent. Without this muffler, dangerous pressure can remain in the pot due to vent freeze-up. Injury or death can result to an operator who removes the abrasive loading cover under pressure.

- In addition, noise levels during blowdown without a CEN can exceed 140db. With the CEN, the noise is reduced to 92db.

- The kit includes a 3" NPT thread connection. As mounting brackets are not included in the kit (due to the restriction on welding on a pressure vessel after certification), customer will need to decide best place for mounting, possibly using the ladder. BlastOne technicians are available - contact us if any questions.

-

GRD32977MB

- Suits 50 gallon and 275 gallon water tanks

- Air Operated, Double Diaphragm, Pneumatic Pump - used to Pump water from a water tank to a MistBlaster

- Allows you to have a mixing tank for HoldTite mixture with water when Mist or Vapor Blasting

- Max Working Pressure 100psi

- Free Flow delivery of 7.0 gallons per minute

- Maximum suction height is 12ft

- Air consumption is only 6scfm

- Pump comes complete with water fittings and air fittings

- Genuine Parts - Manufactured by Graco

GRD32977MB- Suits 50 gallon and 275 gallon water tanks

- Air Operated, Double Diaphragm, Pneumatic Pump - used to Pump water from a water tank to a MistBlaster

- Allows you to have a mixing tank for HoldTite mixture with water when Mist or Vapor Blasting

- Max Working Pressure 100psi

- Free Flow delivery of 7.0 gallons per minute

- Maximum suction height is 12ft

- Air consumption is only 6scfm

- Pump comes complete with water fittings and air fittings

- Genuine Parts - Manufactured by Graco

Blast machine accessories enhance the performance, safety, and efficiency of your blasting operations. Our range includes conversion kits, remote control systems, mufflers, and deadman systems, designed to improve control, reduce noise, and increase safety. Whether you need to upgrade existing equipment or integrate new functionalities, our accessories cater to a variety of blasting needs. From pneumatic to electric conversions to advanced abrasive cut-off systems, these accessories are essential for optimizing your blasting setup, ensuring smoother operations and better results.

My Account

My Account