Blast Equipment

SANDBLASTING MACHINES, EQUIPMENT, WET BLAST SYSTEMS, POTS & ABRASIVE GRIT BLASTING EQUIPMENT

BlastOne has a complete range of sandblasting machines and equipment to suit all your projects & applications. Read our Article to help choose what is for you Blast Machine Equipment Buying Guide From Large to Small Bulk Pots, Mega Blasters, Wet, Slurry, Vapor, Wet, Soda, Standard Blast Pots, Hoppers, Sandblasting Systems & Equipment, Industrial, Ecoquip, Amphi-blasters, Ibix 25 & Ibix 40 Portable & Commercial Grit Equipment. Specialist sandblasting machines and equipment for blasting the internal & externals of pipes, Bulk Tanks for shipyards, and packaged abrasive blasting & air-driers for use on offshore oil & gas platforms, BlastOne has the complete solution, as a leading abrasive sandblasting equipment & grit abrasive supplier. BlastOne has what you need at a convenient location near you. When you need something from large or small, BlastOne is your partner.

Showing 1–15 of 84 results

-

The Clemco Power Gun H2O Portable Suction Wetblaster offers a lightweight, portable solution for wet abrasive blasting. Ideal for spot work and small projects, it is used on projects requiring dust mitigation. Its design eliminates the need for a blast pot, making it perfect for confined spaces and quick setups.

Key Features:

- Portable and lightweight design for easy maneuverability

- Operates without the need for a traditional blast pot

- Ideal for spot work and small-scale projects

- Wet blasting capability reduces dust for safer operation

- Quick setup with minimal equipment requirements

- Suitable for use in confined or hard-to-reach areas

-

SBMGSHeavy Duty Blast Room can be designed for use with any steel or heavy machinery manufacturers, refinishing facilities, for oil and gas components, or in job shops. The "General Purpose Custom Engineered Blast Rooms and Facilities" (SKU: SBMGS) are heavy-duty, long-term sandblasting solutions. Designed for diverse industrial needs, these rooms feature robust steel panels, advanced abrasive recovery systems, and extensive customizability. Ideal for consistent operations seeking a controlled blasting environment.SBMGSHeavy Duty Blast Room can be designed for use with any steel or heavy machinery manufacturers, refinishing facilities, for oil and gas components, or in job shops. The "General Purpose Custom Engineered Blast Rooms and Facilities" (SKU: SBMGS) are heavy-duty, long-term sandblasting solutions. Designed for diverse industrial needs, these rooms feature robust steel panels, advanced abrasive recovery systems, and extensive customizability. Ideal for consistent operations seeking a controlled blasting environment.

-

SBMGRDesigned to improve throughput and lower operating costs in Railcar Facilities, these Blast Rooms are suitable to railcar relining, refurb, or new build.SBMGRDesigned to improve throughput and lower operating costs in Railcar Facilities, these Blast Rooms are suitable to railcar relining, refurb, or new build.

-

Axxiom / Schmidt High Production work-horse for big dry-blast projects! Save time and money when doing large projects.

- Industrial Quality & Design - Manufactured by Schmidt to BlastOne specifications

- Long-life TeraValve metering valves - typically 4-outlets

- High-flow plumbing virtually eliminates pressure drop

- Huge abrasive capacity - Up to 160 cubic feet (aka 8-ton pot) holds half a truckload of garnet! Also available in 120cf, 60cf and 45cf sizes.

- Flexible configuration - Available with:

- Highway Trailer

- Yard Trailer

- Skid mount

- Shipping Legs (for mounting on your own equipment)

- Latest Latest-generation safety features

- HALOK® closure - impossible to open under pressure

- CEN muffler - reduces noise AND prevents freeze-up

- Anti-slip ladder rungs

- Available Performance Enhancing Options

- Bulk Bag Loading Rack - enhances safety while loading

- Hybrid - attached dryer saves space & setup time

- Vacuum loading - saves wait time for cranes where forklift loading of abrasive is prohibited

- Hour meters - management tool monitors nozzle time

- Industrial Quality & Design - Manufactured by Schmidt to BlastOne specifications

-

The Schmidt 3.5cf blast pot offers a perfect mid-sized solution for abrasive blasting projects that are too large for a 1.5cf machine but too tight for a full-size 6.5cf unit. Built with durable, industrial-grade construction, this portable system provides a full 150 PSI working pressure and a range of valve and control options to fit different blasting environments.

- 3.5 cubic foot capacity, ideal for mid-size blasting projects

- Heavy-duty construction with full 150 PSI working pressure

- Choice of abrasive metering valves: Combo/MicroValve III, Thompson II Valve, or TeraValve

- Available with pneumatic or electric control systems for project-specific needs

- Genuine Schmidt® product, manufactured by Axxiom Manufacturing

-

The Schmidt 6.5cf blast pot is the industry’s most popular contractor-sized abrasive blasting machine, designed for larger-scale surface preparation, industrial maintenance, and field service applications. Built with heavy-duty industrial-grade construction, it delivers full 150 PSI working pressure and is configurable with a range of abrasive metering valves and control options to fit demanding jobsite requirements.

- 6.5 cubic foot pot capacity for extended blasting time between refills (up to 950 lbs or 1.5 hours blast time when using a dense media like garnet)

- Heavy-duty construction built for full-shift industrial and contractor use

- Rated for full 150 PSI working pressure

- Choice of abrasive metering valves: Combo/MicroValve III, Thompson II Valve, or TeraValve

- Available with pneumatic or electric control systems and deadman handle options

- Genuine Schmidt® product, manufactured by Axxiom Manufacturing

- Blast Pot Deadman Control System with 50 feet of control line and handle

- Choice of inlet fitting in either 4-claw or Spud type. Spud will be supplied unless otherwise noted in Order Comments field

-

The Schmidt 1.5cf 'Handy Man' blast pot delivers industrial-grade performance in a compact, highly portable design, ideal for spot-work, small blasting projects, and areas where larger pots can't fit. Built with the same rugged construction as full-size models, it offers full 150 PSI working pressure and features precision abrasive metering valves.

- 1.5 cubic foot capacity for small projects and confined areas

- Durable, heavy-duty construction for reliable operation

- Rated for a full working pressure of 150 PSI (10.3 bar)

- Genuine Schmidt® product, manufactured by Axxiom Manufacturing

-

BMS09TERAA-USThe Schmidt 0.9cf MiniBlaster is a compact, portable abrasive blasting unit engineered for precision and mobility in industrial applications. Manufactured in the USA by Axxiom, this unit combines a small footprint with robust construction, making it ideal for spot repairs and projects requiring maneuverability. Selected Features:

- Compact 0.9 cubic foot capacity holds up to 2 bags of garnet

- Equipped with a pressure-hold TeraValve metering valve for precise media control

- Comes with a 25' blast hose and #2 ceramic nozzle

- Integrated screen prevents debris entry, maintaining system integrity

- Weighs 107 lbs and features wheels for easy transport

- SKU: BMS09TERAA-US | MPN: 8023-010

BMS09TERAA-USThe Schmidt 0.9cf MiniBlaster is a compact, portable abrasive blasting unit engineered for precision and mobility in industrial applications. Manufactured in the USA by Axxiom, this unit combines a small footprint with robust construction, making it ideal for spot repairs and projects requiring maneuverability. Selected Features:- Compact 0.9 cubic foot capacity holds up to 2 bags of garnet

- Equipped with a pressure-hold TeraValve metering valve for precise media control

- Comes with a 25' blast hose and #2 ceramic nozzle

- Integrated screen prevents debris entry, maintaining system integrity

- Weighs 107 lbs and features wheels for easy transport

- SKU: BMS09TERAA-US | MPN: 8023-010

-

SBMGT

- Permanent or temporary mounting systems

- Ideal for setting up temporary blasting/painting facilities

- Supplied in modular kit for simple, quick installation (under a week)

- Fully relocatable — easy to install and dismantle

- 100% Waterproof design

- Wind rating as per local requirements

- No concrete foundation necessary

- Compatible with optional abrasive recovery and dust collection equipment

SBMGT- Permanent or temporary mounting systems

- Ideal for setting up temporary blasting/painting facilities

- Supplied in modular kit for simple, quick installation (under a week)

- Fully relocatable — easy to install and dismantle

- 100% Waterproof design

- Wind rating as per local requirements

- No concrete foundation necessary

- Compatible with optional abrasive recovery and dust collection equipment

-

VELOCITYTechnology insertion to exponentially increase shipyard blast and coat production. COMPONENTS & FEATURES The individual technologies include, but are not limited to:

- Intelliblast Blast Pot Controls:

- Smart controls that optimize blasting parameters for maximum efficiency and effectiveness.

- Snakebite Blasting Nozzles

- High-performance nozzles designed for precise and powerful material removal, reducing blasting time and lowering process noise.

- Rapidly Deployable Containments

- Innovative containment systems that can be quickly deployed, ensuring a controlled environment, and minimizing the spread of contaminants.

- Vortex Airflow Movement

- Proprietary airflow design that lowers energy consumption, enhances ventilation, and ensures the efficient removal of particles from the blasting and painting areas.

- Combination Dual Air Plenums

- Dual air plenums that provide a uniform and controlled airflow, optimizing the blasting and painting processes.

- Energy Recovery System (ERS)

- An energy recovery system that captures and recycles heat energy, reducing overall energy consumption and operational costs

- Faster production cycles

- Reduced operational costs

- Enhanced environmental sustainability

- Improved worker safety

VELOCITYTechnology insertion to exponentially increase shipyard blast and coat production. COMPONENTS & FEATURES The individual technologies include, but are not limited to:- Intelliblast Blast Pot Controls:

- Smart controls that optimize blasting parameters for maximum efficiency and effectiveness.

- Snakebite Blasting Nozzles

- High-performance nozzles designed for precise and powerful material removal, reducing blasting time and lowering process noise.

- Rapidly Deployable Containments

- Innovative containment systems that can be quickly deployed, ensuring a controlled environment, and minimizing the spread of contaminants.

- Vortex Airflow Movement

- Proprietary airflow design that lowers energy consumption, enhances ventilation, and ensures the efficient removal of particles from the blasting and painting areas.

- Combination Dual Air Plenums

- Dual air plenums that provide a uniform and controlled airflow, optimizing the blasting and painting processes.

- Energy Recovery System (ERS)

- An energy recovery system that captures and recycles heat energy, reducing overall energy consumption and operational costs

- Faster production cycles

- Reduced operational costs

- Enhanced environmental sustainability

- Improved worker safety

- Intelliblast Blast Pot Controls:

-

The Schmidt® Bulk AmphiBlast™ is a high-capacity wet/dry blasting system (aka Dustless Mega Blaster or Dustless Bulk Pot) that features proven Schmidt controls and innovative moisture injection technology for precise air, abrasive, and water flow control. Available in multiple configurations with up to four independently controlled blast outlets, this system delivers maximum productivity, efficiency, and versatility. Key Features:

- Operate up to four nozzles simultaneously with individual mode settings

- Advanced abrasive metering technology with choice of either the Thompson II or the TeraValve

- Switch between wet blast, dry blast, Softwash™, and blowoff with ease

- Available in 45 cf, 120 cf, and 160 cf capacities

- HALOK® Closure Safety System for enhanced operator protection

- Ergo-Ladder® with anti-slip twisted rungs for safe access

- Mounting options include:

- Shipping Legs - use when mounting on existing customer equipment

- Custom Steel Skid w/forklift pockets

- Yard Trailer

- Highway Trailer

-

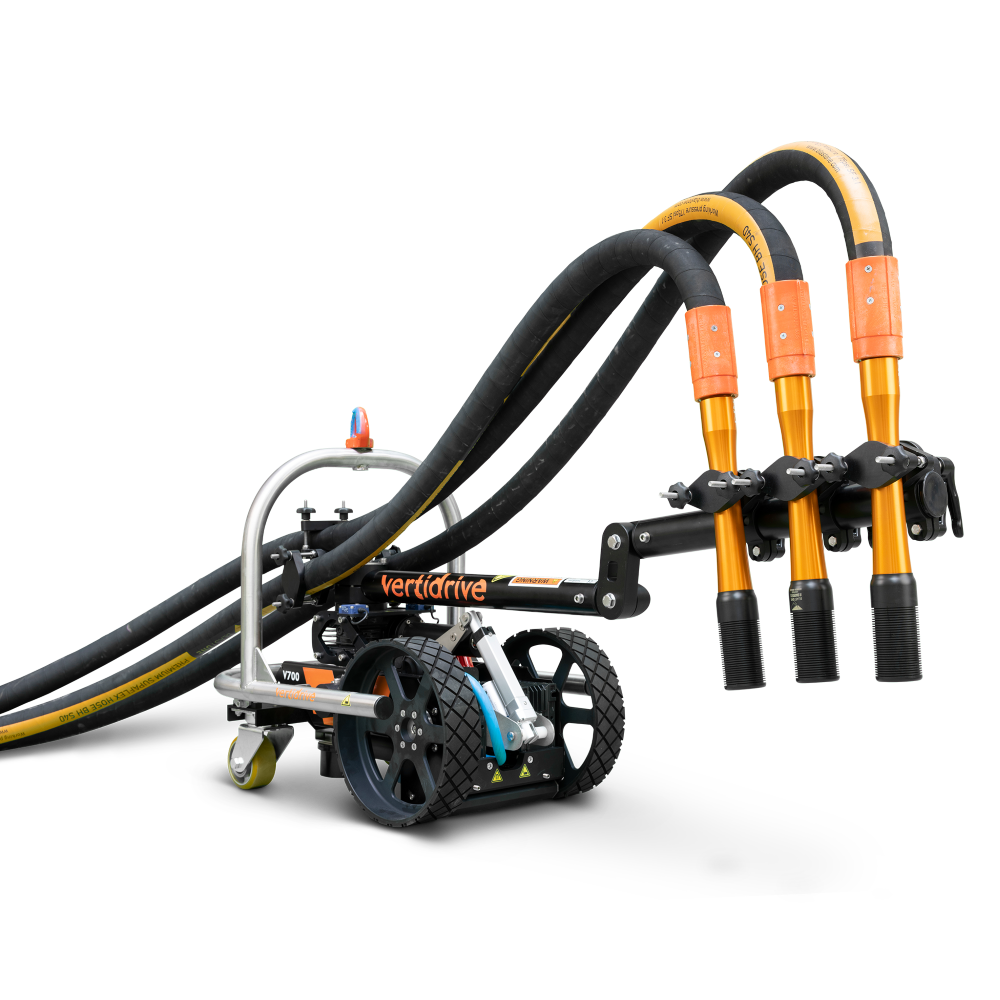

RUBVDV700BlastOne's VertiDrive V700 Blasting Robot represents the cutting edge in surface preparation technology, engineered to revolutionize large-scale blasting projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for performance, efficiency, and safety. RENT or PURCHASE this surface preparation work-horse! The next-generation V700 VertiDrive. Boosting performance and profits on large blasting projects. Purchase pricing is typically between $125,000 and $204,000, depending on configuration. BlastOne can provide on-site training and ongoing support to ensure maximum productivity from Day 1. Schedule a call with our SMEs to calculate and expected ROI for your next project.

- Faster Production. Now holds up to 3 nozzles and each nozzle is up to 30% faster than the best hand blasting. Highest productivity of any robotic blasting system!

- Cleaner Surface. Provides consistent blasting quality by adjustment of equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and now even upside-down!

- Versatile. The V700 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Ultra High Pressure (UHP) coating removal.

- Power Wash surface cleaning.

- Reduced Cost-of-Ownership. The VertiDrive V700 has the lowest maintenance cost of any blasting robot.

- Looking for more information? Click here to read more…

RUBVDV700BlastOne's VertiDrive V700 Blasting Robot represents the cutting edge in surface preparation technology, engineered to revolutionize large-scale blasting projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for performance, efficiency, and safety. RENT or PURCHASE this surface preparation work-horse! The next-generation V700 VertiDrive. Boosting performance and profits on large blasting projects. Purchase pricing is typically between $125,000 and $204,000, depending on configuration. BlastOne can provide on-site training and ongoing support to ensure maximum productivity from Day 1. Schedule a call with our SMEs to calculate and expected ROI for your next project.- Faster Production. Now holds up to 3 nozzles and each nozzle is up to 30% faster than the best hand blasting. Highest productivity of any robotic blasting system!

- Cleaner Surface. Provides consistent blasting quality by adjustment of equipment speed to the specific surface needs.

- Safer. Remote control operation removes the operator from harms way.

- Capable. Boosted magnetic performance allows standard operation on carbon steel surfaces that are horizontal, vertical, and now even upside-down!

- Versatile. The V700 can be configured in 3 ways:

- Abrasive Blasting. Can blast either wet or dry.

- Ultra High Pressure (UHP) coating removal.

- Power Wash surface cleaning.

- Reduced Cost-of-Ownership. The VertiDrive V700 has the lowest maintenance cost of any blasting robot.

- Looking for more information? Click here to read more…

-

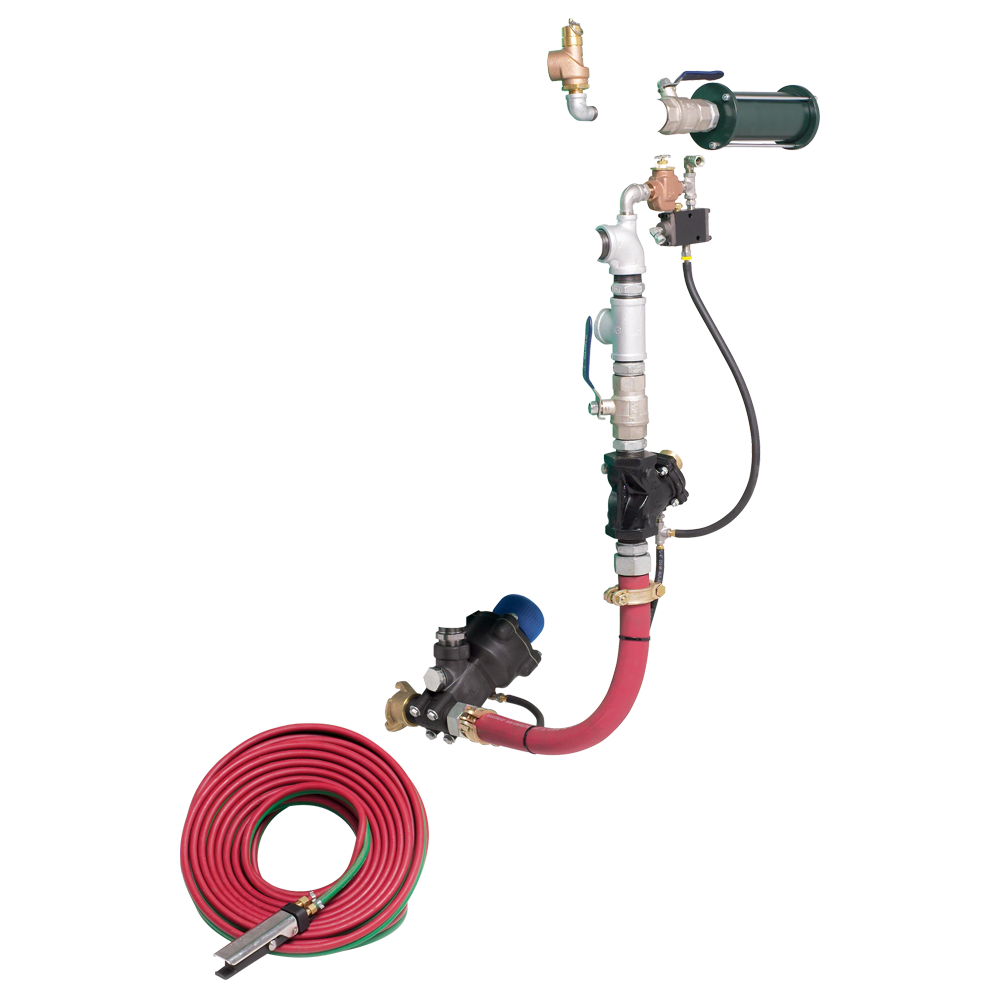

BlastOne's MistBlaster® Wet/Dry Blast Machine is a versatile solution designed to meet the diverse needs of professionals in the blasting industry. This innovative machine, exclusively developed by BlastOne, offers exceptional flexibility with both combo skid and portable configurations, ensuring reliable performance in various project settings. Features:

- Dual-mode blasting: seamless transition between wet and dry blasting.

- Combo skid options: integrate breathing air packages, air dryers, and more…

- … or Portable configuration: with wheels for easy transport and setup.

- Ultra-low water use: just 1 pint/minute in MistBlast mode.

- Enhanced control panel: 4 operational modes (Dry Blast, Wet Blast, Wash Down, Blow Down).

- Reliable TeraValve® abrasive metering system for consistent performance and pressure-hold technology.

- Compatible with most abrasives in dry mode; garnet or crushed glass recommended for wet mode.

- High-flow connections maintain optimal nozzle performance with very low pressure drop.

- 12v Electric Controls for the fastest and safest deadman action

-

BlastOne's 160 CF Mega MistBlaster is the ultimate solution for professionals seeking flexibility in surface preparation. This advanced blast machine, exclusively designed by BlastOne, offers both wet and dry blasting capabilities, making it ideal for large projects where efficiency and versatility are paramount.

- Versatility. 4 functions available at the flip of a switch:

- MistBlasting / Wet (slurry) Blasting

- Traditional Dry Blasting

- Wash-down mode

- Blow-off mode

- Each outlet is independently controlled, giving even greater versatility.

- Capability. With its 4 outlets, this workhorse can power up to 4 operators OR a VertiDrive robotic blaster and manual blasting simultaneously.

- Huge capacity - As typically configured with 160 cubic feet (aka 8 Ton), this bulk pot holds half a truckload of garnet.

- Mount Options as follows:

- Highway Trailer

- Skid Mount

- Shipping Legs (for mounting on your own equipment)

- Available Cost Saving Option - We can convert your existing Schmidt® Dry bulk pot with to our Mega MistBlaster with our retrofit package. Available as a Limited version (without metering / air valves, for new pots) or as a Full version (with all valves, for used pots).

- Versatility. 4 functions available at the flip of a switch:

Why Choose BlastOne’s Blast Equipment?

BlastOne’s blast equipment stands out for its reliability and innovation. Features like ergonomic designs, efficient media usage, and compatibility with various abrasives make our equipment a preferred choice. Our products are backed by expert support and comprehensive training resources, ensuring you get the most out of your investment.

Stay ahead in your projects with equipment that meets stringent industry standards and adapts to evolving needs. Trust BlastOne for solutions that enhance productivity and deliver consistent results.

My Account

My Account

Small Blast Pots

Small Blast Pots Contractor Blast Pots

Contractor Blast Pots Specialty Blast Pots

Specialty Blast Pots MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Mega Bulk Blasters

Mega Bulk Blasters Robotic / Vertidrive Equipment

Robotic / Vertidrive Equipment Track Blasters

Track Blasters Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Blast Machine Accessories

Blast Machine Accessories