Blast Equipment Parts

Showing 256–270 of 377 results

-

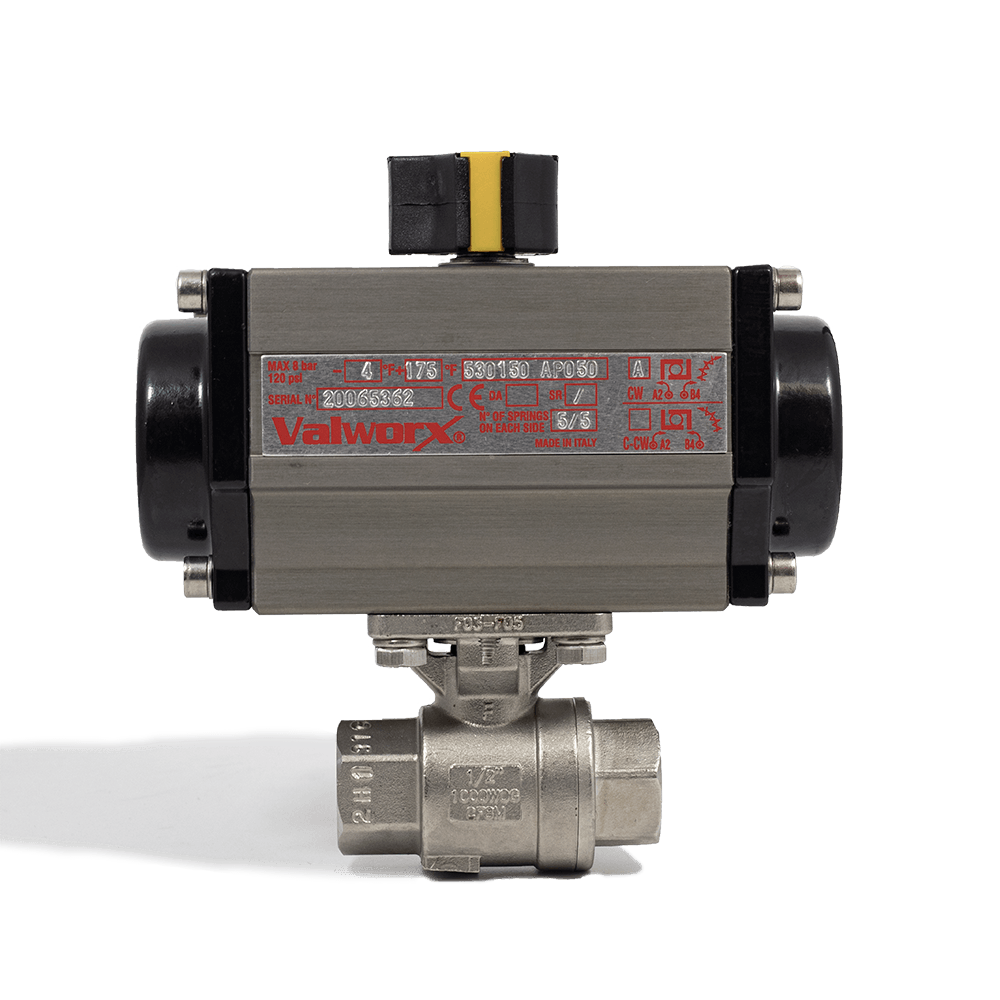

- Multi-purpose inline ball valves

- Plated brass corrosion-resistant body

- Full bore design for maximum airflow

- Rated for use up to 600 psi

- Female NPT threaded ports

- Sold individually

-

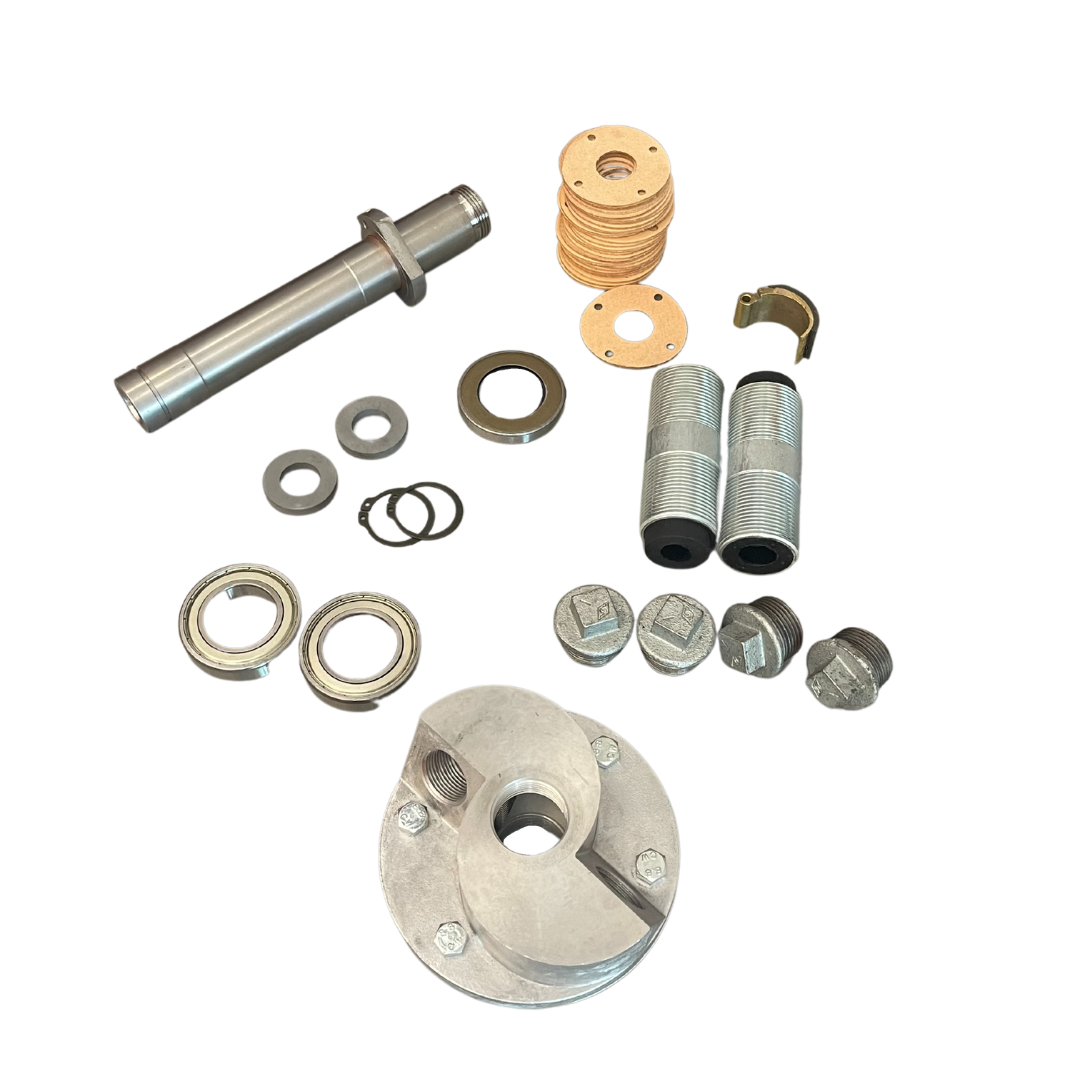

GV01247Clemco Manual Sand Valves are similar in concept to the larger Flat Sand Valve. The MSV abrasive metering valve is used exclusively on machines with ½" piping, such as the 0.5 and 1.0 CF Clemco blast machines. It is best used for expendable mineral and slag abrasives, and is not compatible with fine mesh or glass abrasive. MPN: 01247GV01247Clemco Manual Sand Valves are similar in concept to the larger Flat Sand Valve. The MSV abrasive metering valve is used exclusively on machines with ½" piping, such as the 0.5 and 1.0 CF Clemco blast machines. It is best used for expendable mineral and slag abrasives, and is not compatible with fine mesh or glass abrasive. MPN: 01247

-

GV01260The Clemco Manual Sand Valve (MSV) must be maintained to provide acceptable metering capability. When it needs rebuilt, these OEM Clemco gaskets are readily available at BlastOne. MPN: 01260GV01260The Clemco Manual Sand Valve (MSV) must be maintained to provide acceptable metering capability. When it needs rebuilt, these OEM Clemco gaskets are readily available at BlastOne. MPN: 01260

-

GV02433Clemco Flat Sand Valves (FSV) and Sentinel metering valves must be maintained to provide acceptable metering capability. When these valves need rebuilt, OEM replacement gauge unit indicators are readily available at BlastOne. MPN: 02433GV02433Clemco Flat Sand Valves (FSV) and Sentinel metering valves must be maintained to provide acceptable metering capability. When these valves need rebuilt, OEM replacement gauge unit indicators are readily available at BlastOne. MPN: 02433

-

GV02424The Clemco Flat Sand Valve (FSV) , and the similar LPV (Low profile version) must be maintained to provide acceptable metering capability. When it needs rebuilt, these OEM Clemco gaskets are readily available at BlastOne. Two are required. MPN: 02424GV02424The Clemco Flat Sand Valve (FSV) , and the similar LPV (Low profile version) must be maintained to provide acceptable metering capability. When it needs rebuilt, these OEM Clemco gaskets are readily available at BlastOne. Two are required. MPN: 02424

-

GV03080Clemco Flat Sand Valves and Sentinel metering valves must be maintained to provide acceptable metering capability. When these valves need rebuilt, OEM replacement screws for use on the gauge units are available at BlastOne. MPN: 03080GV03080Clemco Flat Sand Valves and Sentinel metering valves must be maintained to provide acceptable metering capability. When these valves need rebuilt, OEM replacement screws for use on the gauge units are available at BlastOne. MPN: 03080

-

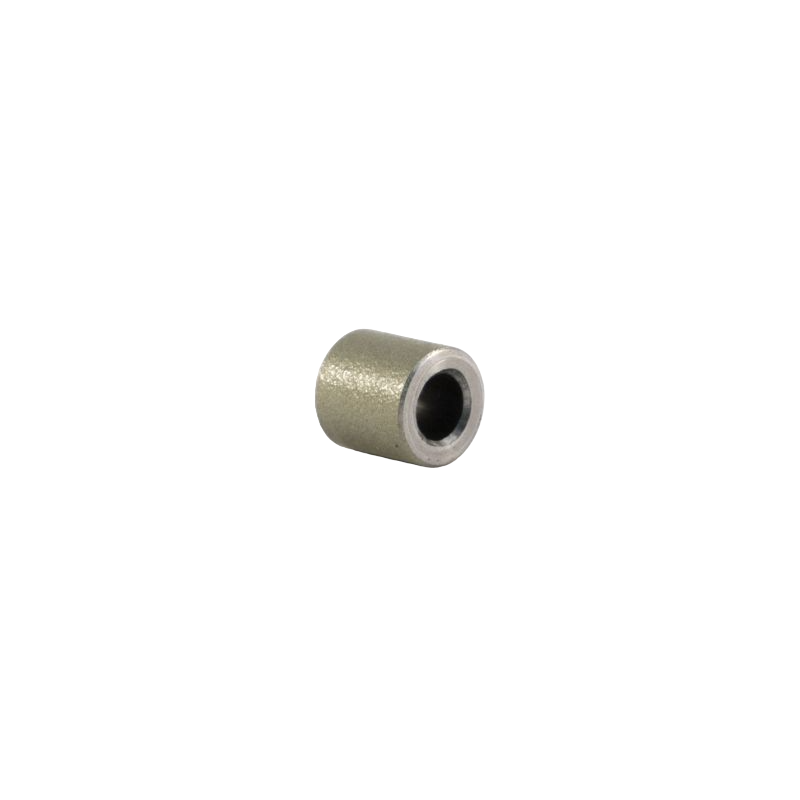

GV02431

The Clemco Flat Sand Valve (FSV) and the Sentinel valve must be maintained to provide acceptable metering capability. When it needs rebuilt, these OEM Clemco replacement handle bolt spacers are readily available at BlastOne.

MPN: 02424

GV02431The Clemco Flat Sand Valve (FSV) and the Sentinel valve must be maintained to provide acceptable metering capability. When it needs rebuilt, these OEM Clemco replacement handle bolt spacers are readily available at BlastOne.

MPN: 02424

-

BlastOne stocks the Axxiom replacement parts you need to keep your valves operating. These are the bottom base pipe nipples for the Thompson II metering valve:

- 1" x 1", MPN 2152-000-19

- 1-¼" x 1-¼", MPN 2152-000-15

- 1-½" x 1-½", MPN2152-000-11

-

BA2497706

- Installed in the riser tube below the pop up valve of the blast pot

- Used to stop backflow of air into the control lines and valves

- Typically used when blasting with fine or dusty abrasives

- Suits 1" riser tubes

- User will need to reduce current riser tube height to make this fit.

- Allows maximum pressure fluctuation without back flow of dust and abrasive.

- Sold individually

- Genuine Parts - Manufactured by Axxiom Manufacturing/Schmidt

BA2497706- Installed in the riser tube below the pop up valve of the blast pot

- Used to stop backflow of air into the control lines and valves

- Typically used when blasting with fine or dusty abrasives

- Suits 1" riser tubes

- User will need to reduce current riser tube height to make this fit.

- Allows maximum pressure fluctuation without back flow of dust and abrasive.

- Sold individually

- Genuine Parts - Manufactured by Axxiom Manufacturing/Schmidt

-

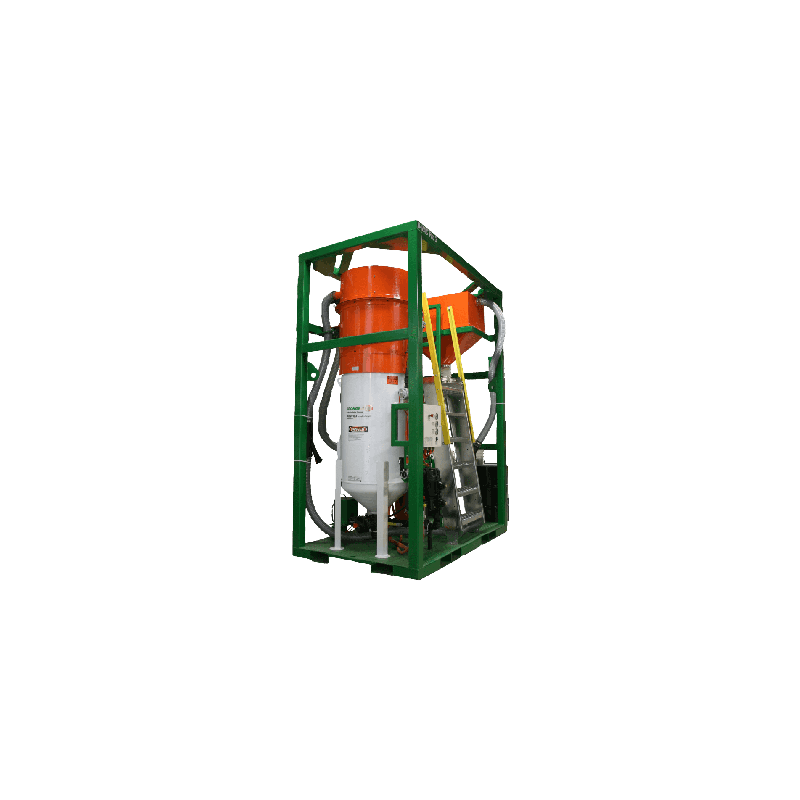

BA840800079

- Essential Safety Item for Megablaster Pot closures

- Designed and installed on all Schmidt Bulk Pots since release in 2010

- Able to be retrofitted to Schmidt Bulk Pots in any of BlastOne Locations

- Ensures that correct operating procedures are followed when opening the fill port.

- Fits over camlock bolts and ensures all bolts remain in the lugs until all cams are fully disengaged, ensuring that the lid can not blow open

- Genuine Parts - Manufactured by Schmidt - Axxiom Manufacturing

BA840800079- Essential Safety Item for Megablaster Pot closures

- Designed and installed on all Schmidt Bulk Pots since release in 2010

- Able to be retrofitted to Schmidt Bulk Pots in any of BlastOne Locations

- Ensures that correct operating procedures are followed when opening the fill port.

- Fits over camlock bolts and ensures all bolts remain in the lugs until all cams are fully disengaged, ensuring that the lid can not blow open

- Genuine Parts - Manufactured by Schmidt - Axxiom Manufacturing

-

GV212800020

- 1-1/4" Heavy Duty Media Inlet Nipple with increased abrasion resistance

- Connects Metering Valve to Blast Pot

- Suits all Schmidt Abrasive Blast Pots, and any other vessel with a 1 1/4" NPT Metering Valve Ports

GV212800020- 1-1/4" Heavy Duty Media Inlet Nipple with increased abrasion resistance

- Connects Metering Valve to Blast Pot

- Suits all Schmidt Abrasive Blast Pots, and any other vessel with a 1 1/4" NPT Metering Valve Ports

Explore our extensive range of blast equipment parts designed to enhance and maintain your blasting operations. From deadman control systems to high-pressure fittings, we provide everything you need to keep your equipment running smoothly and efficiently. Our selection includes durable components like hex pipe nipples, pop-up valves, and hose fittings, ensuring compatibility and high performance. Trust in our products to deliver reliability and safety across all your blasting projects.

My Account

My Account

Abrasive Metering Valves & Parts

Abrasive Metering Valves & Parts Air Control Valves & Related

Air Control Valves & Related Deadman / Control Systems

Deadman / Control Systems General Repair Parts for Blast Pots

General Repair Parts for Blast Pots Internal Pipe (ID) System Components

Internal Pipe (ID) System Components MistBlaster Specific Parts

MistBlaster Specific Parts Sponge Blast Equipment Parts

Sponge Blast Equipment Parts Vacuum Blaster Workheads, Parts & Related

Vacuum Blaster Workheads, Parts & Related VertiDrive Specific Parts

VertiDrive Specific Parts