Blast Equipment Parts

Showing 196–210 of 367 results

-

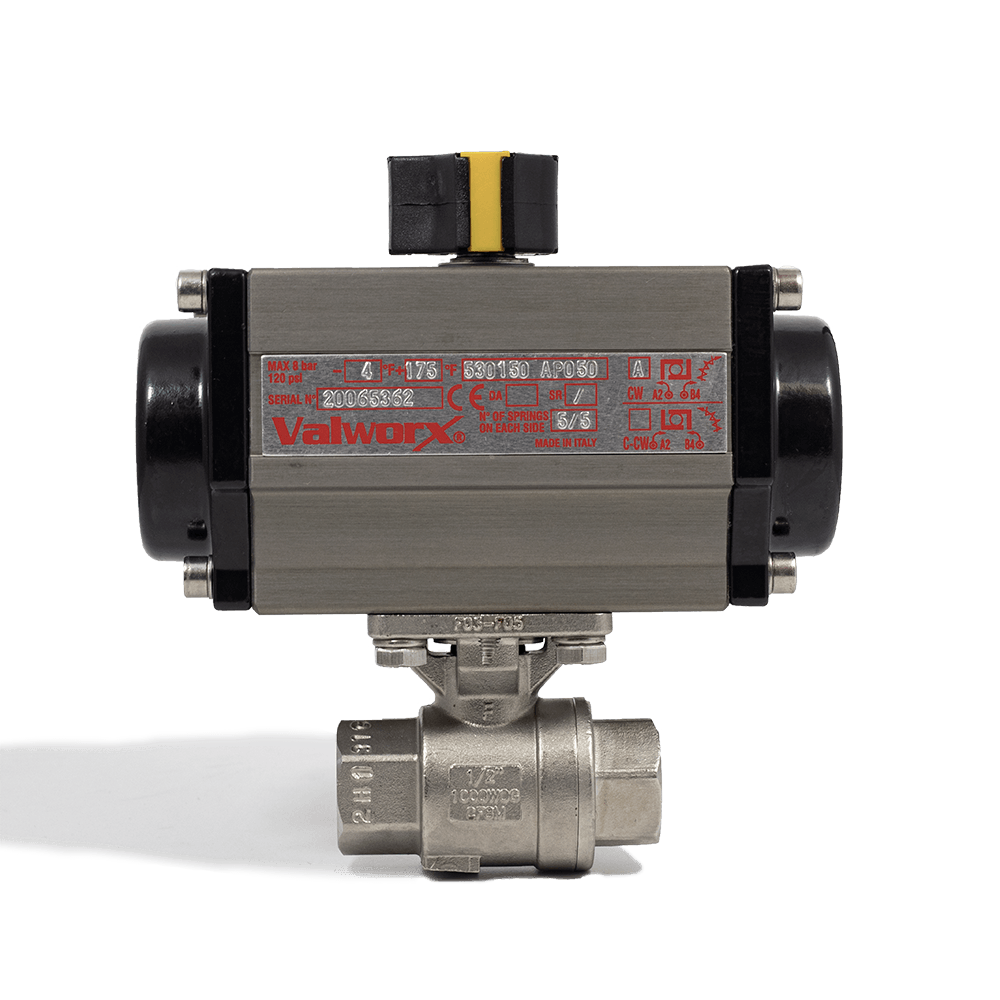

- Pressure-release deadman control valve i.e., blast machine depressurizes when the deadman handle is released.

- Used when an overhead hopper automatically feeds abrasive into a blast machine.

- Rugged stainless steel body, compact, isolated 2-bolt construction.

- Doubles blast machine refill cycle time.

- Virtual Position Indicator illustrates orifice size, giving the ability to set abrasive flow quickly and consistently.

- Set and forget – flow rates stay set where you put them.

- High wear, rugged plunger seal.

- Stainless steel body for long life.

- Improved urethane clean-out port enabling quick removal of obstructions while improving port and valve life.

- Fit a rebuild kit while the valve is still fitted to the blast machine.

- Sold individually.

- Genuine Products – Manufactured by Schmidt / Axxiom Manufacturing

-

Enhance your blasting efficiency with the Schmidt® MicroValve Abrasive Metering Valve. Designed for precise abrasive flow, this rugged valve ensures optimal sandblasting media use.

- The MicroValve™ changed the industry by providing accurate metering valve

- Most pressure-release Schmidt pots now use the newer MicroValve® 3

- Simple screw type metering through a low-wearing valve

- 1 ¼" (32 mm) thread abrasive inlet port

- Hardened steel threaded base nipple

- Sold Individually, Brass Coupling not included

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

- The MicroValve™ changed the industry by providing accurate metering valve

-

The Thompson Valve II XL™ showcases Axxiom's continuous improvement process. Adding XL™ technology to the legendary Thompson valve, this premium valve lasts up to 10 times longer than all previous Thompson valves, due to its unique engineering.

- Withstands aggressive medias (like steel grit or aluminum oxide) and high-wear dusty abrasives.

- Will support up to a #12 (3/4") blast nozzle

- Upgraded components and internal wipers to keep the critical areas protected

- Most universal of the Axxiom XL™ series of valves - supports robotic, high-volume blasting

- Sold Individually

- Many choices of sizes and tungsten sleeve configurations, as follows:

- 1" base, std. sleeve. MPN: 2153-006

- 1.25" base, std. sleeve. MPN: 2153-007

- 1.5" base, std. sleeve. MPN: 2153-008

- 1.25" base, slotted sleeve. MPN: 2153-217

- 1.5" base, slotted sleeve. MPN: 2153-218

- 1.25" base, multi-port sleeve. MPN: 2153-437

- 1.5" base, multi-port sleeve. MPN: 2153-438

- (slotted and multi-port sleeves are designed to limit the maximum abrasive flow, saving abrasive when the valve is opened too far.)

-

The Thompson I Valve was invented by Bob Schmidt and was instrumental in causing the popularity of pressure hold technology.

- Pressure-hold systems retain the pressure in the blast pot until the deadman handle is depressed. This reduces abrasive and energy waste.

- The Thompson I offers fine control for abrasive metering

- It comes in 3 nipple size configurations:

- 1 ¼” (32 mm) x 1 ¼” (32 mm)

- 1 ½" (38 mm) x 1 ½" (38 mm)

- 2" (50 mm) x 2" (50 mm)

- Threaded-plunger metering design with air actuated operation

- Fits most sand blast hoppers, blast pots or abrasive blasting machines

- Genuine Parts - Manufactured by Schmidt® / Axxiom Manufacturing

-

GV31158The Clemco GritWizard Metering Valve, 1.5" with Ball Valve (MPN: 31158) is a pneumatically operated, pressure-hold valve designed for maximum efficiency in abrasive blasting. Compatible with all common media types, it delivers consistent media flow, precise adjustments, and unmatched durability, making it the ultimate choice for contractors and industrial applications. Features:

- Universal Compatibility: Works with all common abrasive media out-of-the-box.

- Precision Metering: Adjustments calibrated to 20 turns per inch with a numbered gauge for accuracy.

- On-the-Fly Adjustments: Adjust media flow while the valve is actuated.

- Durable Design: 12x longer lifespan with 60% fewer wear parts.

- Weight: 18 lbs; Clearance: 13" (w/ shutoff valve), 10.5" (w/o shutoff valve).

- Pressure Range: Operates between 80–175 psi.

GV31158The Clemco GritWizard Metering Valve, 1.5" with Ball Valve (MPN: 31158) is a pneumatically operated, pressure-hold valve designed for maximum efficiency in abrasive blasting. Compatible with all common media types, it delivers consistent media flow, precise adjustments, and unmatched durability, making it the ultimate choice for contractors and industrial applications. Features:- Universal Compatibility: Works with all common abrasive media out-of-the-box.

- Precision Metering: Adjustments calibrated to 20 turns per inch with a numbered gauge for accuracy.

- On-the-Fly Adjustments: Adjust media flow while the valve is actuated.

- Durable Design: 12x longer lifespan with 60% fewer wear parts.

- Weight: 18 lbs; Clearance: 13" (w/ shutoff valve), 10.5" (w/o shutoff valve).

- Pressure Range: Operates between 80–175 psi.

-

GV02427

- The Flat Sand Valve is the classic Clemco abrasive metering valve used for sandblasting for nearly 100 years.

- Used in most new Classic blast machine pots

- The FSV is simple and economical and provides abrasive metering control for expendable mineral abrasives and slags (not recommended for steel grit or aluminum oxide).

- The valve uses a simple lever and keyslot to control the flow of abrasive from the blast pot into the blast hose

- It is good practice to keep a complete spare valve on hand to use when needed, repairing the worn valve at a convenient later time.

- Genuine Clemco Part Number 02427

GV02427- The Flat Sand Valve is the classic Clemco abrasive metering valve used for sandblasting for nearly 100 years.

- Used in most new Classic blast machine pots

- The FSV is simple and economical and provides abrasive metering control for expendable mineral abrasives and slags (not recommended for steel grit or aluminum oxide).

- The valve uses a simple lever and keyslot to control the flow of abrasive from the blast pot into the blast hose

- It is good practice to keep a complete spare valve on hand to use when needed, repairing the worn valve at a convenient later time.

- Genuine Clemco Part Number 02427

-

The Flat Sand Valve is legacy metering technology, where the metering is performed by sliding a lever to open and close the abrasive port. It is simple in design and relatively inexpensive, but has a few limitations. Details as follows:

- Slide-plate metering design, controlled by lever

- 1 1/4" (32 mm) ports

- Features side cleanout-inspection port

- Available with or without outlet nipple and Y-piece (Optional rubber lined nipple is available to extend nipple life.)

- The major limitations are:

- Not recommended for use with metallic abrasives

- The slide plate/lever design does not provide effective fine metering control. Typically this results in over consumption of media. For low-volume blasting using inexpensive media, this may not be an issue.

-

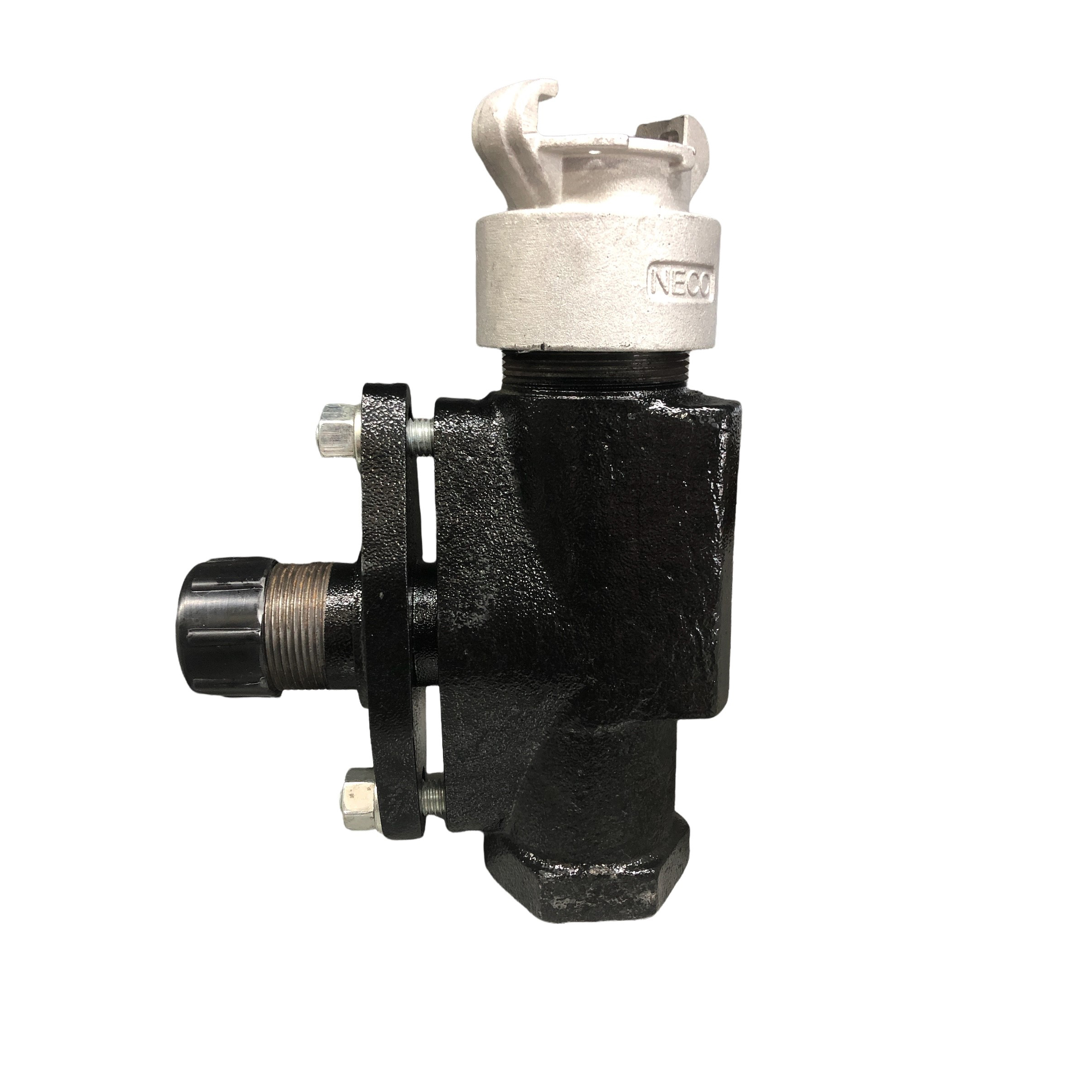

GVDNV100

- HFSTC3 blast coupling included

- Designed for use with coarse metallic abrasives

- Heavy cast iron construction

- Not recommended for use with fine abrasives

- 1 1/2" NPT female thread air connection

- Recommended upgrade: MicroValve 3

GVDNV100- HFSTC3 blast coupling included

- Designed for use with coarse metallic abrasives

- Heavy cast iron construction

- Not recommended for use with fine abrasives

- 1 1/2" NPT female thread air connection

- Recommended upgrade: MicroValve 3

-

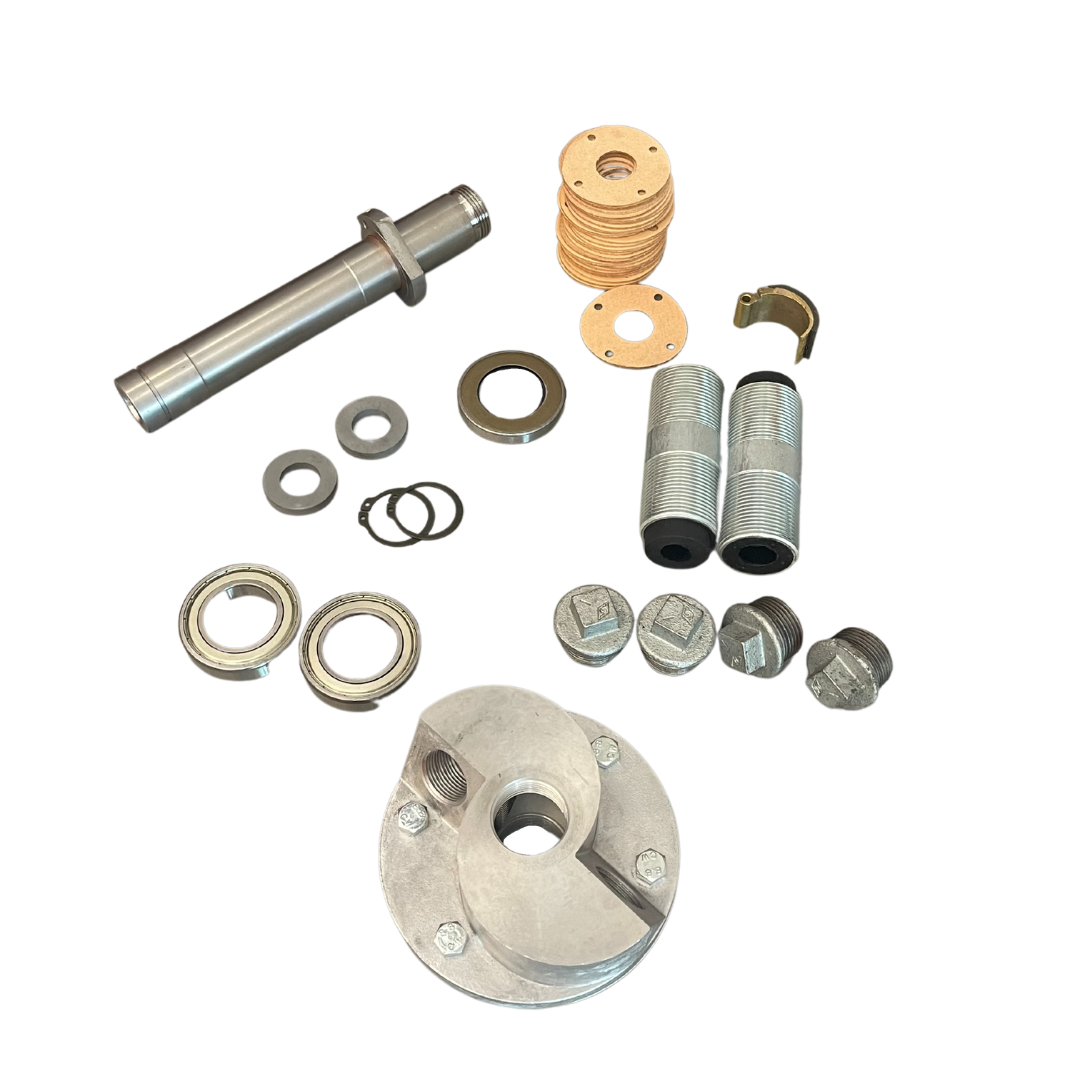

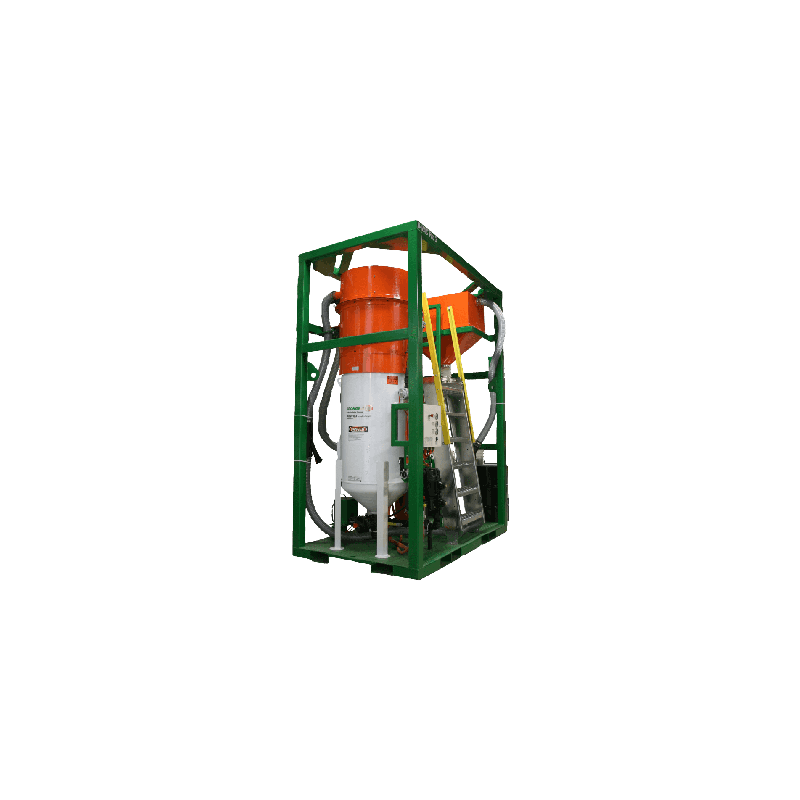

RUBVD422007BlastOne has the parts needed to keep your VertiDrive equipment running. This is the recommended spare parts kit for the V400 and includes the following:

- ESCON 70/10 Motor Controller CCB4.0

- V400 WCS with Connector

- Harting Han-Eco Locking Lever (2)

- Gearbox 050 with Flange

- V400 Motor Assembly

- Relay Module

- Carabine Hook (2)

- Lock Pin SS D10-L40 (2)

- Lock Pin SS D12-L70 (2)

- Wearplate (2)

- Spring (6)

- Spring Holder Nut (12)

- Vacuum Pan Skirt

RUBVD422007BlastOne has the parts needed to keep your VertiDrive equipment running. This is the recommended spare parts kit for the V400 and includes the following:- ESCON 70/10 Motor Controller CCB4.0

- V400 WCS with Connector

- Harting Han-Eco Locking Lever (2)

- Gearbox 050 with Flange

- V400 Motor Assembly

- Relay Module

- Carabine Hook (2)

- Lock Pin SS D10-L40 (2)

- Lock Pin SS D12-L70 (2)

- Wearplate (2)

- Spring (6)

- Spring Holder Nut (12)

- Vacuum Pan Skirt

-

RUBVD422009BlastOne has the parts needed to keep your VertiDrive equipment running. This is the recommended spare parts kit for the V700 and includes the following:

- ESCON 70/10 Motor Controller CB4.0

- Actuator 35.43 in with Connector

- V700 WCS with Connector

- Limit Switch with Connector

- Harting Han-Eco Locking Lever

- Swingarm Clamp with Shaft, includes key

- Gearbox 050 with Flange

- V700 Motor Assembly

- Relay Module

- Castor Wheel

RUBVD422009BlastOne has the parts needed to keep your VertiDrive equipment running. This is the recommended spare parts kit for the V700 and includes the following:- ESCON 70/10 Motor Controller CB4.0

- Actuator 35.43 in with Connector

- V700 WCS with Connector

- Limit Switch with Connector

- Harting Han-Eco Locking Lever

- Swingarm Clamp with Shaft, includes key

- Gearbox 050 with Flange

- V700 Motor Assembly

- Relay Module

- Castor Wheel

-

RUBVD223015BlastOne has the parts needed to keep your VertiDrive equipment running. This is the ESCON 70/10 Motor Controller CB4.0.RUBVD223015BlastOne has the parts needed to keep your VertiDrive equipment running. This is the ESCON 70/10 Motor Controller CB4.0.

-

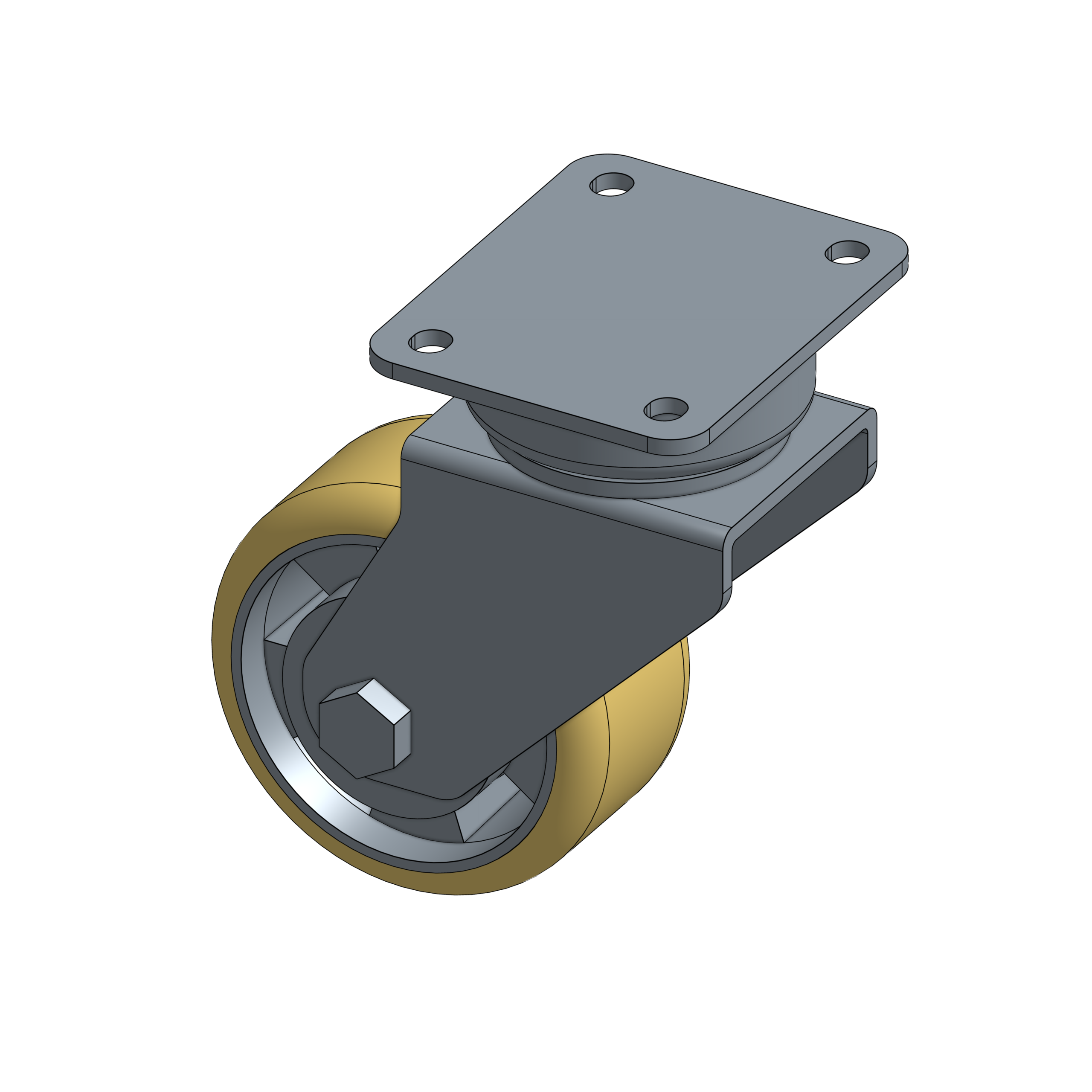

RUBVD113531BlastOne has the parts needed to keep your VertiDrive equipment running. This is the Castor Wheel.RUBVD113531BlastOne has the parts needed to keep your VertiDrive equipment running. This is the Castor Wheel.

-

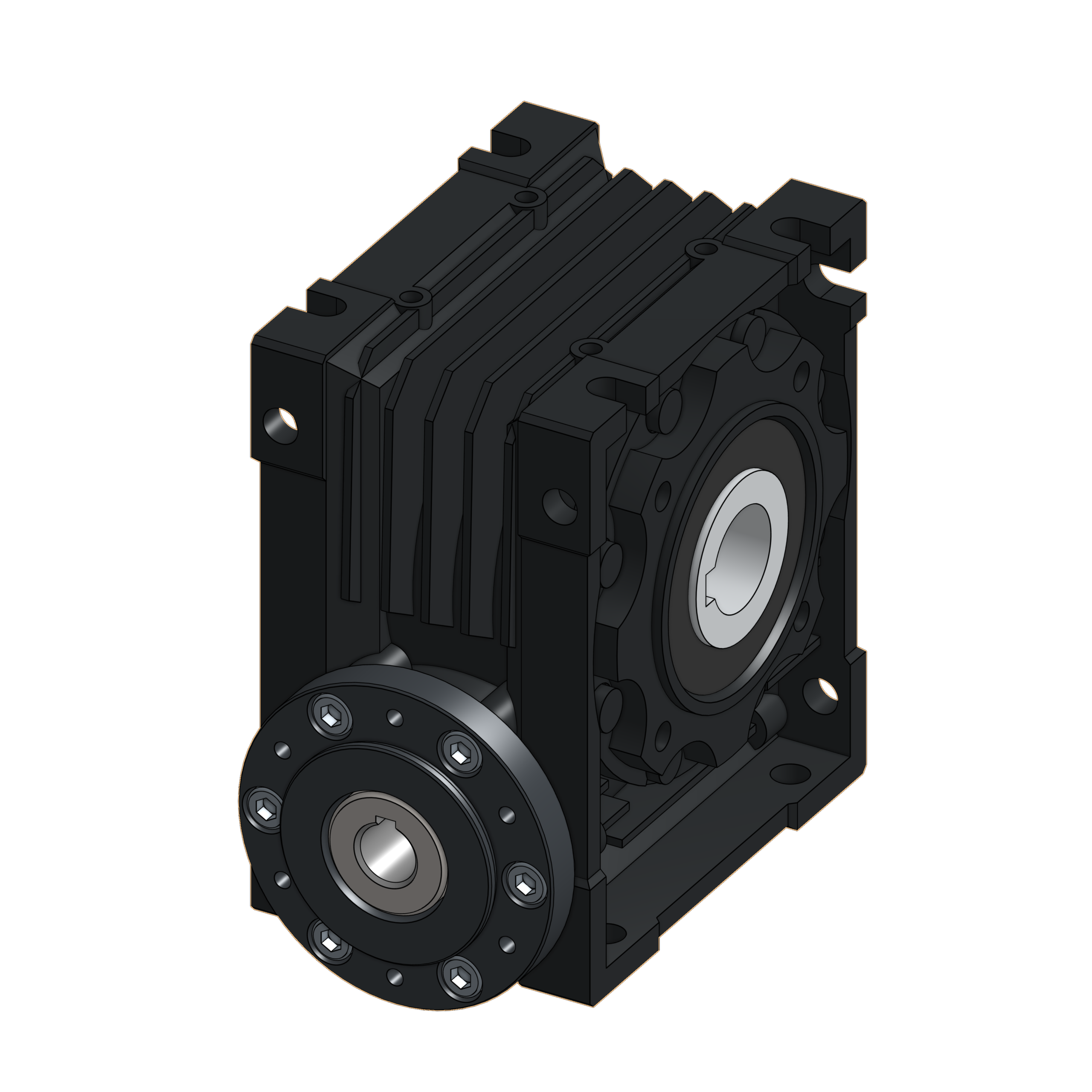

RUBVD322074BlastOne has the parts needed to keep your Vertidrive equipment running. This is the Gearbox 050 with Flange.RUBVD322074BlastOne has the parts needed to keep your Vertidrive equipment running. This is the Gearbox 050 with Flange.

-

RUBVD322010BlastOne has the parts needed to keep your VertiDrive equipment running. This is the Limit Switch with Connector.RUBVD322010BlastOne has the parts needed to keep your VertiDrive equipment running. This is the Limit Switch with Connector.

Explore our extensive range of blast equipment parts designed to enhance and maintain your blasting operations. From deadman control systems to high-pressure fittings, we provide everything you need to keep your equipment running smoothly and efficiently. Our selection includes durable components like hex pipe nipples, pop-up valves, and hose fittings, ensuring compatibility and high performance. Trust in our products to deliver reliability and safety across all your blasting projects.

My Account

My Account

Abrasive Metering Valves & Parts

Abrasive Metering Valves & Parts Air Control Valves & Related

Air Control Valves & Related Deadman / Control Systems

Deadman / Control Systems General Repair Parts for Blast Pots

General Repair Parts for Blast Pots Internal Pipe (ID) System Components

Internal Pipe (ID) System Components MistBlaster Specific Parts

MistBlaster Specific Parts Sponge Blast Equipment Parts

Sponge Blast Equipment Parts Vacuum Blaster Workheads, Parts & Related

Vacuum Blaster Workheads, Parts & Related VertiDrive Specific Parts

VertiDrive Specific Parts